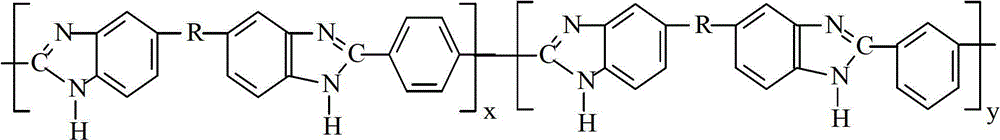

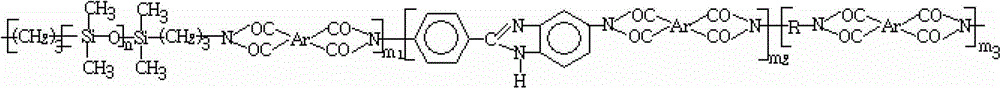

Organosilicon polyimide benzimidazole photoconductive fiber coating layer and preparation method thereof

A technology of silicon polyimide and benzimidazole, which is applied in the field of optical fiber coating layer and its preparation, can solve the problems of application limitation, low temperature resistance level, poor resistance to cold and heat alternating cycle, etc. Fewer types, easy to recycle, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] At room temperature, put 7.7 g (0.01 mol) of organosilicon diamine (YASI), 2000 g of N-ethyl-2-pyrrolidone (NMP) and 300 g of tetrahydrofuran (THF) into the reaction kettle, stir and dissolve, then add 344.1 g (1.11 moles) of 3,3',4,4'-tetracarboxydiphenyl ether dianhydride (ODPA), and after stirring for 1 hour, 22.4 g (0.1 moles) of 2-(4-aminophenyl)-5 -Aminobenzimidazole (APABI) and 200.0 g (1.0 mole) 4,4'-diaminodiphenyl ether (DADPE), after stirring for 5 hours, 2874.2 g of homogeneous transparent viscous silicone polyamic acid phenyl And imidazole resin solution, the solid content is 20%, recorded as PSIMZ-20.

Embodiment 2

[0057] At room temperature, put 76.6 g (0.1 mole) of organosilicon diamine (YASI), 5800 g of N,N-methylacetamide (DMAc) and 700 g of methyltetrahydrofuran (MTHF) into the reaction kettle, stir and dissolve, Add 322.2 g (1.0 mol) of 3,3',4,4'-tetracarboxybenzophenone dianhydride (BTDA), 87.2 g (0.4 mol) of pyromellitic dianhydride (PMDA), and stir for 2 hours , add 22.4 g (0.1 mole) 2-(4-aminophenyl)-5-aminobenzimidazole (APABI) and 20.0 g (0.1 mole) 3,4'-diaminodiphenyl ether (34DADPE), 51.8 g (0.1 mol) 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane (BAPFP), 200.0 g (1.0 mol) 4,4'-diaminodiphenyl ether (DADPE), After stirring and reacting for 4 hours, 7280.2 g of a homogeneous transparent and viscous organosilicon polyamic acid benzimidazole resin solution with a solid content of 10.7% was obtained, designated as PSIMZ-10.

Embodiment 3

[0059] At room temperature, mix 76.6 g (0.1 mol) of silicone diamine (YASI), 1000 g of N-methyl-2-pyrrolidone (NMP), 1000 g of N,N-methylacetamide (DMAc) and 400 g of methyl Put tetrahydrofuran (MTHF) into the reaction kettle, stir and dissolve, add 156.0 g (0.3 moles) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propanedianhydride (BPADA), 218.0 grams (1.0 moles) of pyromellitic dianhydride (PMDA), after stirring for 1 hour, add 22.4 grams (0.1 moles) of 2-(4-aminophenyl)-5-aminobenzimidazole (APABI) and 51.8 g (0.1 mole) 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane (BAPFP), 200.0 g (1.0 mole) 4,4'-diaminodiphenyl ether (DADPE) After stirring and reacting for 5 hours, 2874.2 grams of homogeneous transparent and viscous organosilicon polyamic acid benzimidazole resin solution was obtained, with a solid content of 23.2%, which was designated as PSIMZ-23.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com