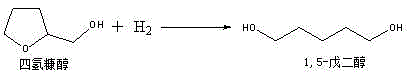

Method for continuously preparing 1, 5-pentanediol from tetrahydrofurfuryl alcohol

A technology for tetrahydrofurfuryl alcohol and pentanediol, which is applied in the field of continuous preparation of 1,5-pentanediol, can solve the problems of low selectivity of 1,5-pentanediol, dependence on petroleum resources for raw materials, difficulty in separation and purification, and the like, Achieving the effect of wide concentration range, simple process and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Thoroughly mix 30.0 grams of zirconium hydroxide and 4.15 grams of ammonium metatungstate, add 20 ml of distilled water to adjust the rheological state, and carry out rheological phase reaction at 80~90 °C for 24 hours, then dry at 110 °C and dry at 700 °C Calcining at low temperature for 2-4 hours to obtain tungsten-zirconium composite oxide. Take 10 grams of tungsten-zirconium composite oxide, impregnate it with 6.8 ml of chloroplatinic acid aqueous solution containing 30.0 mg platinum / ml for 10-12 hours, dry it at 110 °C, and roast it at 450 °C for 3 hours to obtain the metal element platinum: tungsten: Catalyst with zirconium molar ratio=0.19:1.0:13.0.

[0026] A tubular fixed-bed reactor with a length of 60 cm and an inner diameter of 10 mm was used. Load 5 grams of catalyst with a particle size of 20-40 mesh, and conduct hydrogen reduction activation at 200°C for 1 hour. , 2 MPa, the mass flow rate of tetrahydrofurfuryl alcohol is 0.75 g / hour, and the hydrogen / t...

Embodiment 2

[0028] Reaction raw material is the tetrahydrofurfuryl alcohol aqueous solution of mass concentration 80%, and other conditions are all identical with embodiment 1. The product obtained from the reaction was analyzed by gas chromatography. The conversion rate of tetrahydrofurfuryl alcohol was 65.1%, the selectivity of the target product 1,5-pentanediol was 86.1%, the selectivity of the by-product n-pentanol was 10.5%, and the selectivity of other by-products was 3.4%.

Embodiment 3

[0030] Reaction raw material is mass concentration 60% tetrahydrofurfuryl alcohol aqueous solution, other conditions are all identical with embodiment 1. The product obtained from the reaction was analyzed by gas chromatography. The conversion rate of tetrahydrofurfuryl alcohol was 81.5%, the selectivity of the target product 1,5-pentanediol was 88.0%, the selectivity of the by-product n-pentanol was 10.9%, and the selectivity of other by-products was 1.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com