Preparation method and application for heterogeneous olefin polymerization catalyst

A technology for olefin polymerization and catalyst, applied in the field of olefin polymerization catalyst and its preparation, can solve problems such as no reports, and achieve the effects of easy separation and purification, high activity, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a heterogeneous olefin polymerization catalyst, using a magnesium-containing compound as a carrier, and using a sulfonylamine compound as an internal electron donor, the preparation steps are as follows:

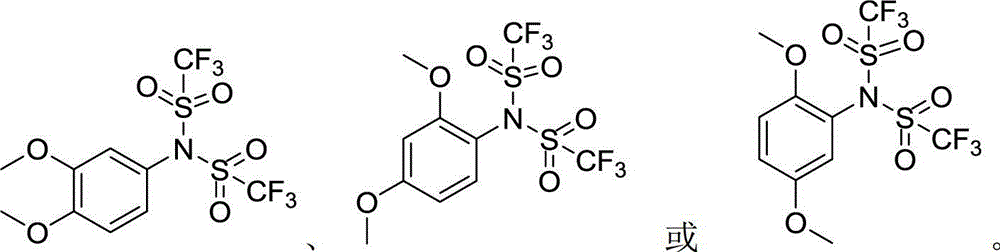

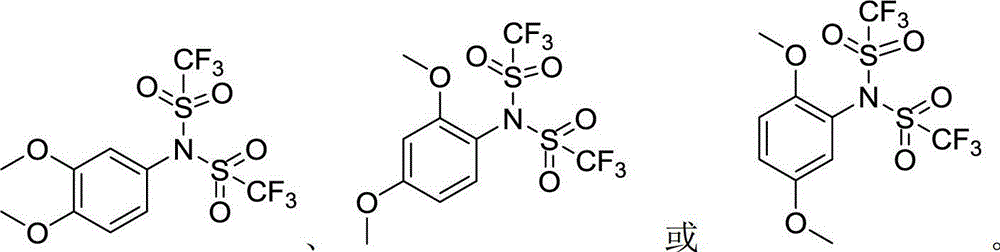

[0025] 1) Preparation of sulfonylamine compounds:

[0026] Add 10mmol 3,4-dimethoxyaniline and 20mmol triethylamine into a 100ml schlenk bottle, add 40ml dichloromethane under a nitrogen atmosphere, stir and dissolve thoroughly, then place it in a DFY-80 low temperature reaction bath to -78 ℃, dropwise add 10ml of dichloromethane solution with a concentration of 2mmol / ml trifluoromethanesulfonic anhydride, the reaction mixture is fully stirred during the dropwise addition, rise to room temperature after the dropwise addition, and stir at room temperature or heated to solvent reflux for 2h to The reaction is sufficient, the reaction mixture is washed twice with distilled water, each time with one volume of distilled water, after the above two was...

Embodiment 2

[0035] A preparation method of a heterogeneous olefin polymerization catalyst, the preparation steps are as follows:

[0036] 1) Preparation of sulfonylamine compounds: the same as in Example 1;

[0037] 2) Preparation of heterogeneous olefin polymerization catalyst:

[0038] Pre-cool 60ml of titanium tetrachloride to -15°C, then add 2g of magnesium alkoxide MgCl 2 (EtOH) 2.5 Add the pre-cooled titanium tetrachloride to carry out the first titanium loading reaction, then raise the temperature to 0°C at a heating rate of 1°C / 5min, and then heat it to 40°C after naturally rising to room temperature, and add 0.099g of the above-mentioned sulfur Acyl amine compounds, at the same time, 0.067g dibutyl phthalate (a commonly used internal electron donor) was added to investigate the effect of compound use. After half an hour of reaction, it was raised to reflux temperature, stirred and heated for 2 hours, and the reaction solution was brownish black, the upper layer liquid is brown...

Embodiment 3

[0042] A preparation method of a heterogeneous olefin polymerization catalyst, the steps are as follows:

[0043] 1) Preparation of sulfonylamine compounds:

[0044] Add 10mmol 2,4-dimethoxyaniline and 20mmol triethylamine to a 100ml schlenk bottle, add 40ml dichloromethane under a nitrogen atmosphere, stir and dissolve thoroughly, and place it in a DFY--80 low-temperature reaction bath to -78 ℃, dropwise add 10ml of dichloromethane solution with a concentration of 2mmol / ml trifluoromethanesulfonic anhydride, the reaction mixture is fully stirred during the dropwise addition, rise to room temperature after the dropwise addition, and stir at room temperature or heated to solvent reflux for 2h to The reaction is sufficient, the reaction mixture is washed twice with distilled water, each time with one volume of distilled water, after the above two washings and liquid separation, the organic phase is collected, fully dried with anhydrous magnesium sulfate, and the solvent is evapo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com