Sensing film ion selective electrode prepared by film dropping method

A technology of ion-selective electrodes and sensing membranes, applied in the direction of material analysis, measuring devices, and instruments through electromagnetic means, can solve problems such as high assembly process requirements, affecting electrode performance, and membrane deformation and arching, so as to improve economic benefits , Electrode performance is reliable and stable, and the effect of saving film making time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

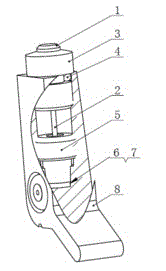

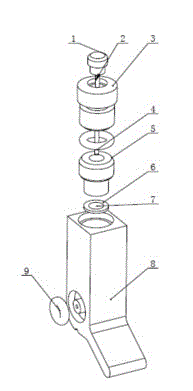

[0028] Example 1~6, such as Figure 1~4 As shown, the preparation of the drop film method induction membrane ion selective electrode:

[0029] 1. Membrane dripping: drip the prepared ionic membrane liquid into the PVC ring 6 under the condition of the fume hood. After the solvent in the previous film liquid is evaporated to dryness, another layer of film liquid is dropped, and the film is dripped repeatedly in this way to form a K, Cl, Ca or other ion-sensitive film 7 with the same thickness as the PVC ring 6 .

[0030] 2. Make the electrode core: Weld the contact 1 with the Ag / AgCl wire 2, and then bond the contact 1 with the mounting head 3 with epoxy resin, and insert the O-ring a4 into the groove of the mounting head 3.

[0031] 3. Electrode chamber: Put the PVC ring 6 that has been filmed into the inner cavity of the electrode body 8 (the surface of the last layer of film faces down), then put the pressure ring 5 into the electrode body 8, and press the pressure ring 5...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap