Instant yolk powder and preparation method thereof

An egg yolk powder and instant technology, which is applied in the field of egg yolk powder production and preparation of instant egg yolk powder, can solve problems such as lack of competitiveness of products, and achieve the effects of not easy exposure and good emulsifying performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

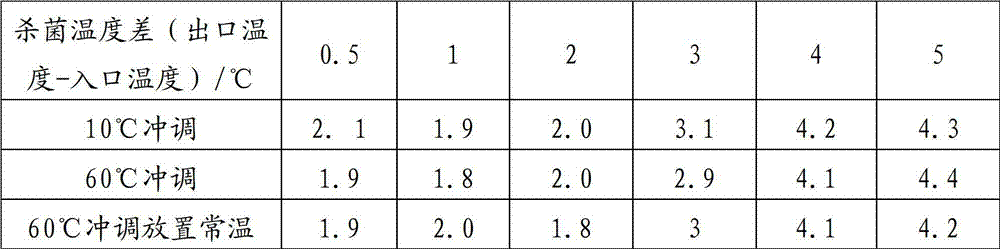

[0091] Take 2.5kg of beaten egg yolk, send it into a homogenizer for homogenization, and adjust the homogenization pressure to 20MPa; weigh 20.5ml of phospholipase A, add it to the homogenized egg yolk, and then heat it at 4°C Stir for 16 hours; pasteurize the egg yolk after stirring and heat preservation, the sterilization temperature is 60°C, the pasteurization temperature is 59°C, and the sterilization time is 210s; the pasteurized egg yolk is spray-dried, and the centrifugal spraying is carried out. The wind temperature is 160°C, and the outlet air temperature is 78°C, and 1040g of egg yolk powder is obtained; the egg yolk powder is boiled and granulated to obtain 930g of egg yolk powder.

[0092] The obtained egg yolk powder can be quickly dispersed in water, the upper layer has no lumps, and forms a uniform and stable solution.

Embodiment 2

[0094] Take 2.5kg of beaten egg yolk, use a colloid mill for preliminary emulsification, and send it to a homogenizer for homogenization treatment, adjusting the homogenization pressure to 10MPa; weigh 20.3ml of phospholipase A, add it to the homogenized egg yolk and then stirred at 0° C. for 18 hours; the stirred egg yolk liquid was spray-dried, the inlet air temperature of the centrifugal spray was 170° C., and the outlet air temperature was 80° C. to obtain egg yolk powder.

Embodiment 3

[0096] Take 3.0kg of beaten egg yolk, emulsify it with a colloid mill at a low speed, then homogenize it with a homogenizer, and adjust the homogenization pressure to 15MPa; weigh 20.7ml of phospholipase A, add it to the homogenized egg yolk Then stir at 10°C for 13 hours; pasteurize the egg yolk liquid after stirring and heat preservation, the sterilization temperature is 65°C, the pasteurization temperature is 64°C, and the sterilization time is 120s; pasteurize the egg yolk liquid after pasteurization Spray drying, the inlet air temperature of the centrifugal spray is 180°C, and the outlet air temperature is 75°C to obtain egg yolk powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com