Polyvinylamine composite membrane and preparation method and application thereof

A technology of polyvinylamine and polyvinylamine layer, which is applied in the field of CO2 gas separation membrane and its preparation, can solve problems such as difficult to improve, achieve good separation performance, and increase the effect of carrier concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

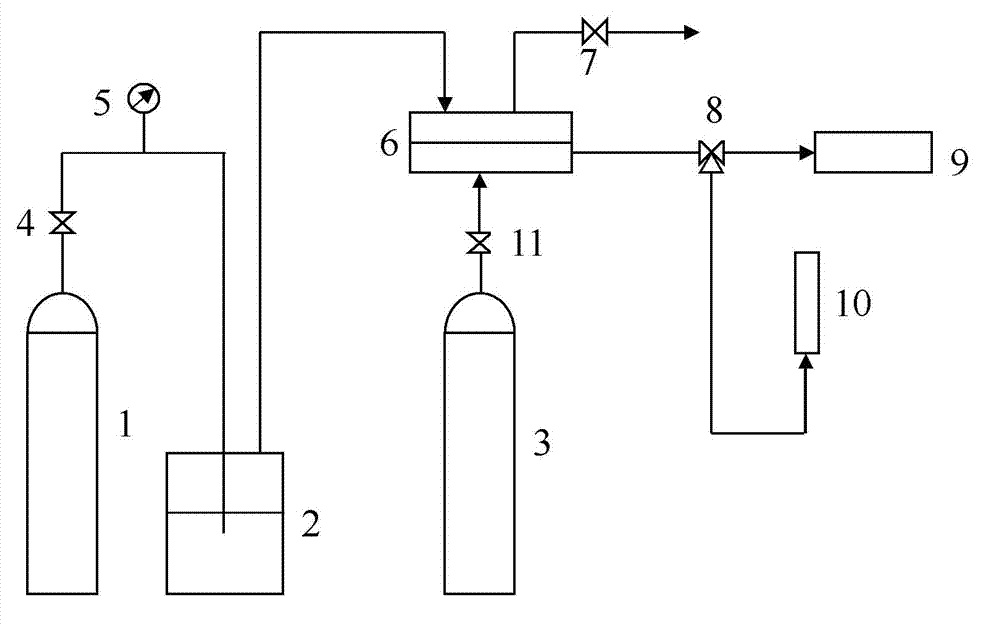

Method used

Image

Examples

preparation example Construction

[0042] In one embodiment of the present invention, the preparation method of the present invention comprises the following steps:

[0043] 1. Basement membrane pretreatment: use a flat membrane made of polysulfone, polyethersulfone, polyacrylonitrile, polyimide, polyetherimide and other materials with a molecular weight cut-off of 5000-50,000 as the basement membrane, and cut the membrane into 130×150mm, immersed in pure water, soaked at room temperature for 20-24 hours, then dried at a temperature of 20°C-60°C and a relative humidity of 10%-70%, for 10h-15h, and set aside.

[0044] 2. Preparation of coating solution: Dissolve PVAm in pure water at a concentration of 1wt%-9wt%, and at the same time add fluorine-containing water-soluble salts (such as sodium fluoride, silver fluoride, ammonium fluoride, potassium fluoride, fluorine Cesium chloride, etc. are made into an aqueous solution at a concentration of 1wt%-30wt%, and the two are mixed according to the molar ratio of amin...

Embodiment 1

[0060] Prepare an aqueous solution of PVAm (for the synthesis process, refer to Fan Hui, Wang Jintang, Synthesis and Application of Polyvinylamine, Chemical Times, 2005, 19(10): 45), and make the mass concentration 2%. An aqueous solution of cesium fluoride CsF (Tianjin Guangfu Fine Chemical Research Institute) was blended therein, and mixed according to PVAm:CsF=1:1 (based on the molar ratio of amine group:fluorine). After magnetic stirring for 4 hours, it was filtered as a coating solution. Vacuumize the prepared coating solution in a vacuum oven for 24 hours for defoaming. Soak a 130×150mm polysulfone flat membrane (molecular weight cut-off 20,000) in pure water for 24 hours, then dry it in a constant temperature and humidity box (40°C, 30% relative humidity, dry for 6 hours), and fix it on a special aluminum plate with medical tape Then place it on the bottom plate of the manual film scraping machine, adjust the height of the scraper to 100 μm, use a dropper to evenly dro...

Embodiment 2

[0064]The aqueous solution of PVAm was prepared as in Example 1, and the mass concentration was 2%. An aqueous solution of cesium fluoride CsF was added thereto, and mixed so that PVAm:CsF=1:2 (in terms of molar ratio of amine group:fluorine). After magnetic stirring for 4 hours, it was filtered as a coating solution. Vacuumize the prepared coating solution in a vacuum oven for 24 hours for defoaming. Soak a 130×150mm polysulfone flat membrane (molecular weight cut off 20,000) in pure water for 24 hours, then dry it in a constant temperature and humidity chamber (40°C, 30% relative humidity, dry for 6 hours) and fix it on a special aluminum plate with medical tape Then place it on the bottom plate of the manual film scraping machine, adjust the height of the scraper to 100 μm, use a dropper to evenly drop the coating solution on the film surface, and push the scraper holder to move from one end of the flat film to the other end to complete the film scraping. The composite fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com