Electrodialysis device applicable to treatment on high-salinity wastewater from industries such as coal chemical industry

A high-salt wastewater, electrodialysis technology, applied in general water supply saving, dispersed particle separation, separation methods, etc., can solve the problems of low freshwater recovery rate, difficult long-term stable operation, low concentration ratio, etc., to overcome the low freshwater recovery rate. , The effect of promoting engineering application and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Simulation of electrodialysis treatment of high-salt wastewater in industries such as coal chemical industry

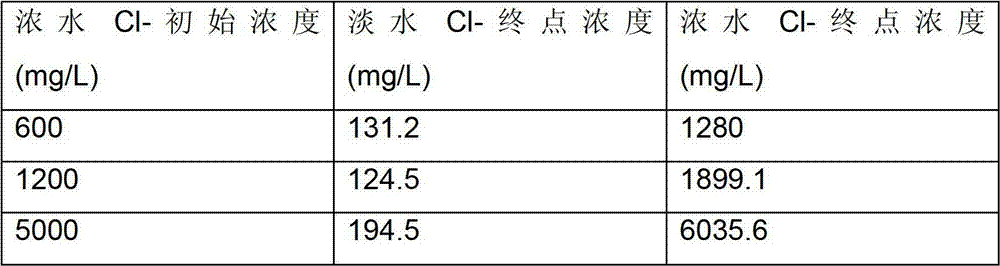

[0035] Simulate the conventional electrodialysis treatment of high-salt wastewater sampling in coal chemical industry and other industries, and carry out in the small membrane stack in the laboratory. Adopt constant pressure, constant temperature, cycle intermittent operation. Initial conditions: The simulated coal chemical high-salt wastewater is prepared with NaCl, and the Cl in the fresh water - Ion is 1200mg / L, Cl in concentrated water - The ions are 600, 1200, 5000mg / L, and the circulating flow rate of fresh water and concentrated water is 60L / h; the polar water uses analytical pure Na 2 SO 4 Preparation, the concentration is about 20g / L, and its circulation flow is 30L / h.

[0036] Experimental results: When the initial concentration of Cl- in fresh water is 1200mg / L, the results after continuous treatment with conventional electrodialysis fo...

Embodiment 2

[0040] Example 2 Electrodialysis treatment of real coal chemical high-salt wastewater

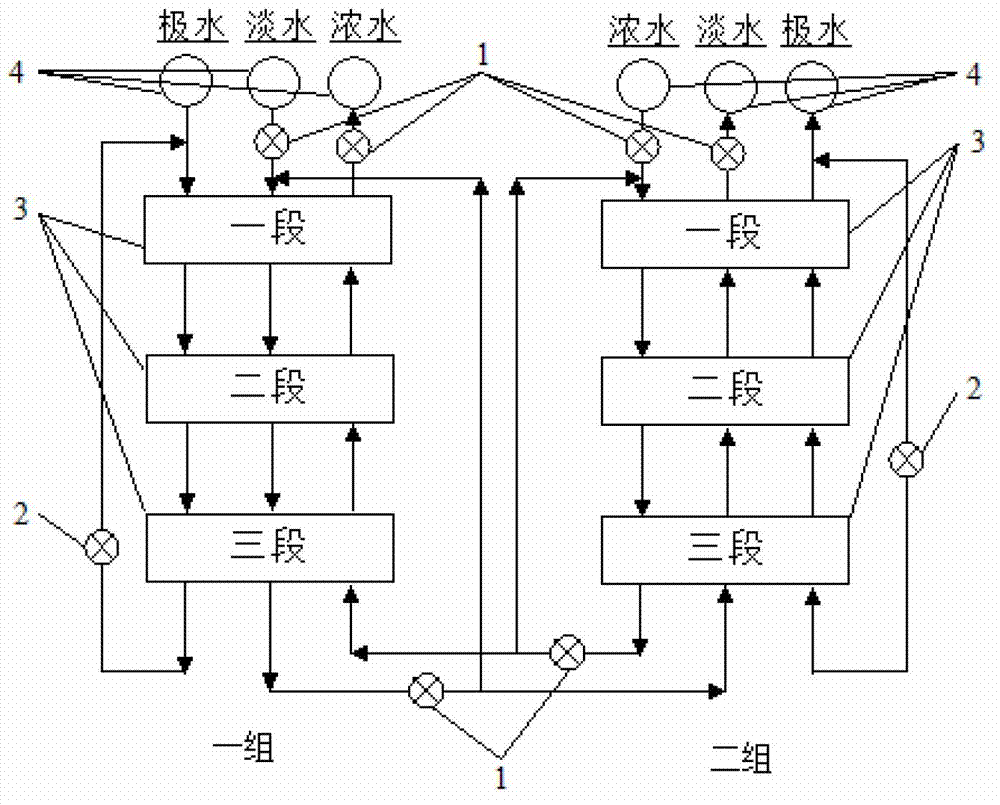

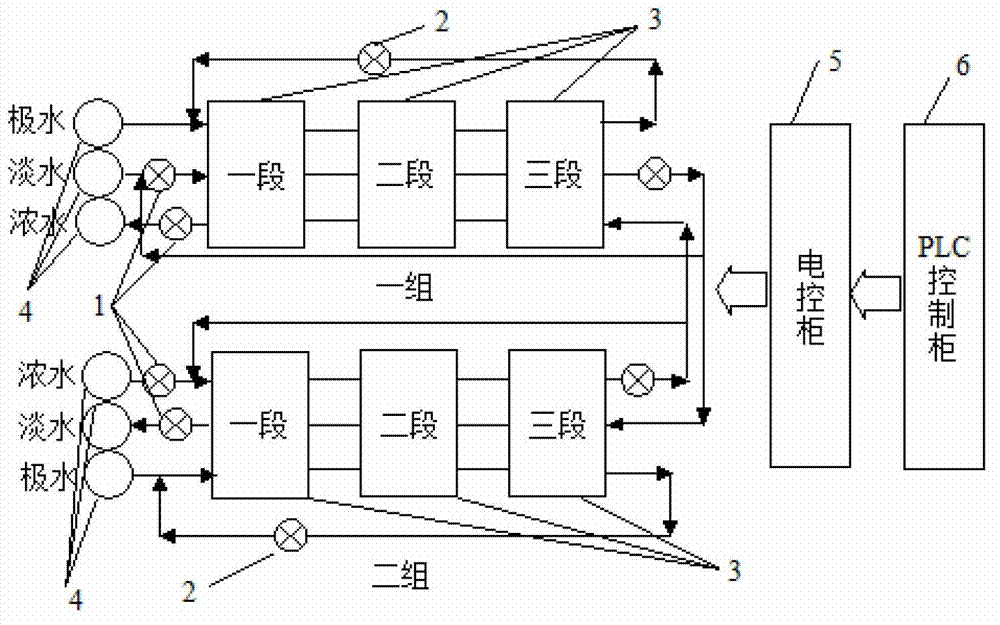

[0041] A test of treating real coal chemical high-salt wastewater by using the multi-stage / countercurrent / inversion electrodialysis device of the present invention. The operating conditions are: control constant pressure 22V, flow rate 300L / h, number of membrane pairs for each membrane stack is 20 pairs, 6 membrane stacks in series (divided into 2 groups, of which 3 membrane stacks are in a group), each group of membrane stacks The inner pole water circulates in the three membrane stacks, and the flow direction of fresh water and concentrated water is opposite. According to the desalination rate or the concentration multiple, the fresh water or concentrated water of each group of membrane stacks enters the next group of membrane stacks for further treatment or is directly discharged; frequent pole reversal is controlled by PLC units, solenoid valves and rectifiers. The influent of the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com