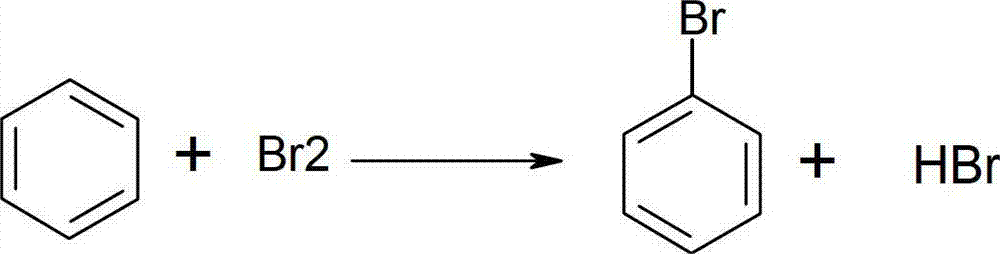

Method for producing by-product hydrobromic acid in synthesis of bromobenzene

A technology of hydrobromic acid and bromobenzene, applied in bromine/hydrogen bromide, chemical instruments and methods, preparation of halogenated hydrocarbons, etc., can solve problems such as deep appearance after being placed for a long time, and achieve the effect of normal appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a 1000L reactor equipped with stirring, with a 4m enamel packing tower and a partial condenser, put 468KG of benzene, and then put in 0.6KG of catalyst anhydrous ferric trichloride, and raise the temperature to 75°C. Drop into 480KG bromine in the bromine dropping tank. Open the top decondenser to feed in and out water, raise the temperature of the synthesis kettle to about 75°C, keep the reflux state in the tower, open the valve at the bottom of the bromine dropping tank in the reaction kettle to add bromine dropwise, and the dropping time is 8hr. During the process, the reaction temperature was gradually increased, and the system always maintained a slight reflux state in the tower. After the dropwise addition, the temperature was maintained at 95-105°C for 2 hours. Tail gas is absorbed by falling film water in three stages in series, adding 240kg of water to each stage, and the absorption temperature is 15~60°C. The synthetic solution is debenzene-removed and ref...

Embodiment 2

[0024] In a 1000L reactor equipped with stirring, with a 4m enamel packing tower and a partial condenser, put 312KG of benzene into it, then put in 0.6kg of iron powder, and raise the temperature to 75°C. Drop into 512KG bromine in the bromine dropping tank. Open the top decondenser to feed in and out water, raise the temperature of the synthesis kettle to about 75°C, keep the reflux state in the tower, open the valve at the bottom of the bromine dropping tank in the reaction kettle to add bromine dropwise, and the dropping time is 10hr. During the process, the reaction temperature is gradually increased, and the system always maintains a slight reflux state in the tower. After the dropwise addition, the reaction temperature is maintained at 100-110°C for 2 hours. Tail gas is absorbed by falling film water in three stages in series, adding 260kg of water to each stage, and the absorption temperature is 15~60°C. The synthetic solution is debenzene and refined to obtain 470.9KG...

Embodiment 3

[0026] In a 1000L reactor equipped with stirring, with a 4m enamel packing tower and a partial condenser, put 312KG of benzene into it, then put in 1.0kg of aluminum trichloride, and raise the temperature to 75°C. Drop into 512KG bromine in the bromine dropping tank. Open the top decondenser to feed in and out water, raise the temperature of the synthesis kettle to about 75°C, keep the reflux state in the tower, open the valve at the bottom of the bromine dropping tank in the reaction kettle to add bromine dropwise, and the dropping time is 10hr. During the process, the reaction temperature is gradually increased, and the system always maintains a slight reflux state in the tower. After the dropwise addition, the reaction temperature is maintained at 100-110°C for 2 hours. Tail gas is absorbed by falling film water in three stages in series, adding 260kg of water to each stage, and the absorption temperature is 15~60°C. The synthetic solution is debenzene and refined to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com