A clean fuel engine powder metallurgy high-speed steel valve seat and its preparation process

A powder metallurgy and high-speed steel technology is applied in the field of powder metallurgy high-speed steel valve seats for clean fuel engines and their preparation. Effect of Seat Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

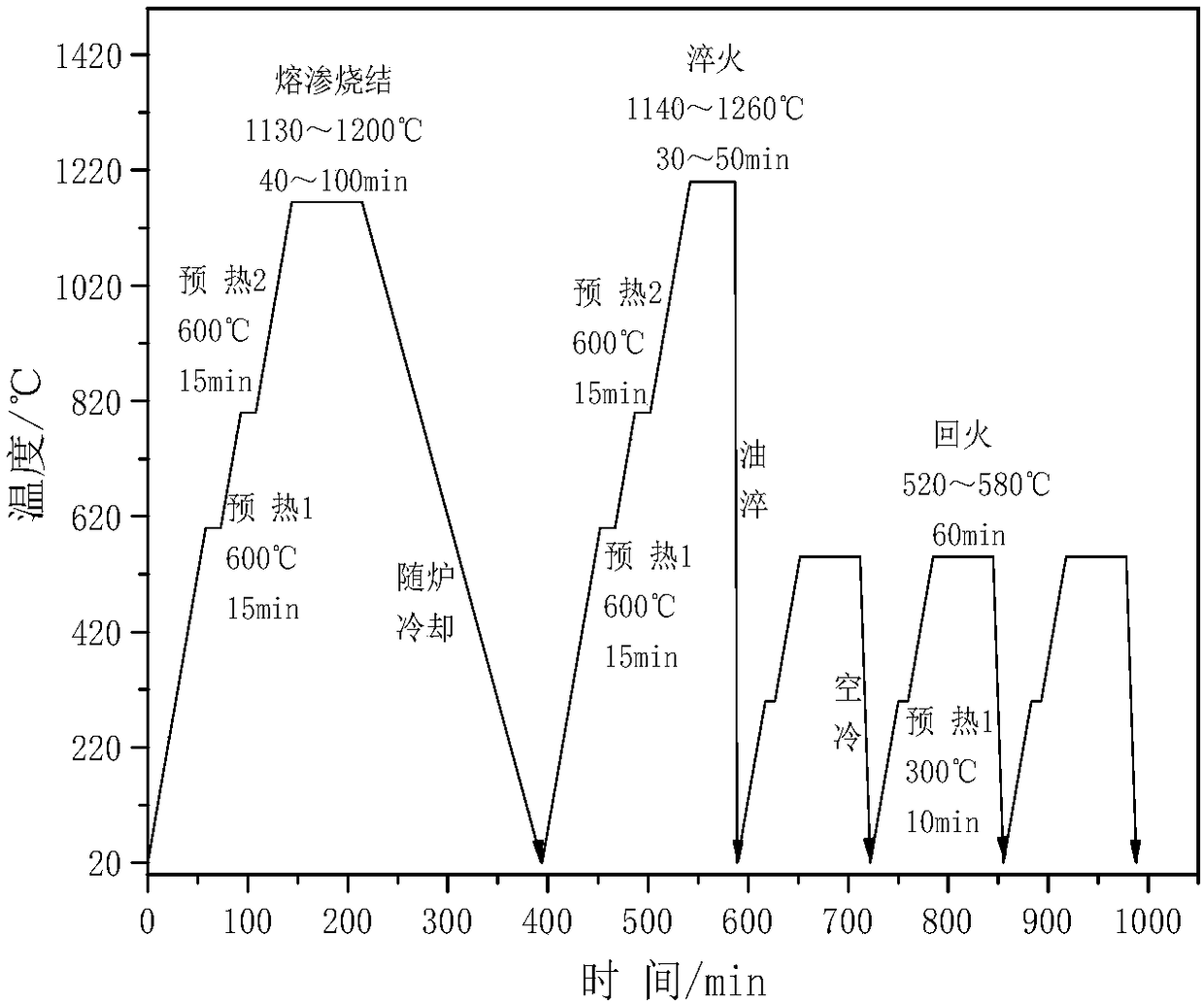

[0036] (1) Carry out direct infiltration sintering in a vacuum sintering furnace, heat preservation at 600°C and 800°C for 15 minutes, heat preservation at 1165°C for 40-100 minutes, and a heating rate of 10°C / min, and cool with the furnace after infiltration sintering is completed.

[0037] (2) Heat to 1140°C in a vacuum quenching furnace, keep it warm for 30-50 minutes, and the heating rate is 10°C / min, quench it in warm oil (about 50°C), then heat it to 300°C for 10 minutes, and keep it at 520°C for 60 minutes. Tempering treatment 3 times.

[0038] (3) Machining into finished products

Embodiment 2

[0040] (1) Carry out direct infiltration sintering in a vacuum sintering furnace, heat preservation at 600°C and 800°C for 15 minutes, heat preservation at 1165°C for 40-100 minutes, and a heating rate of 10°C / min, and cool with the furnace after infiltration sintering is completed.

[0041] (2) Heat to 1180°C in a vacuum quenching furnace, keep it warm for 30-50min, and the heating rate is 10°C / min, quench it in warm oil (about 50°C), then heat it to 300°C and keep it for 10min, and keep it at 580°C for 60min, Tempering treatment 3 times.

[0042] (3) Machining into finished products

Embodiment 3

[0044] (1) Carry out direct infiltration sintering in a vacuum sintering furnace, heat preservation at 600°C and 800°C for 15 minutes, heat preservation at 1165°C for 40-100 minutes, and a heating rate of 10°C / min, and cool with the furnace after infiltration sintering is completed.

[0045] (2) Heat to 1220°C in a vacuum quenching furnace, keep it warm for 30-50 minutes, and the heating rate is 10°C / min, quench in warm oil (about 50°C), then heat to 300°C and keep it for 10 minutes, and keep it at 520°C for 60 minutes, Tempering treatment 3 times.

[0046] (3) Machining into finished products

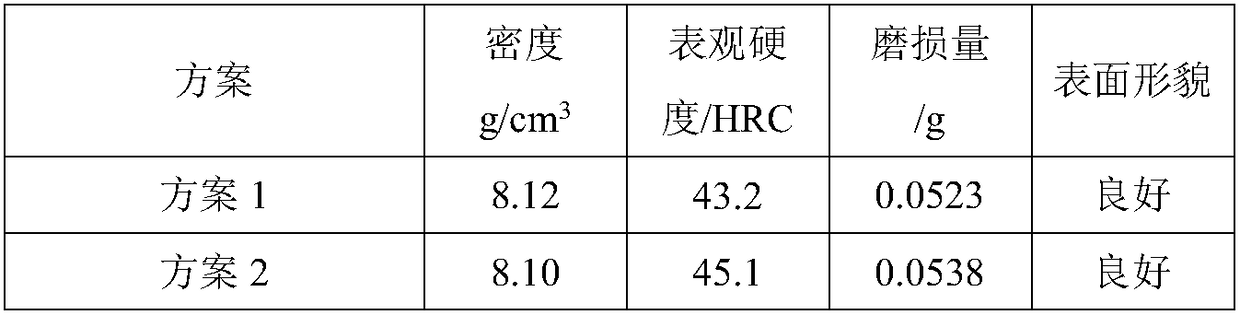

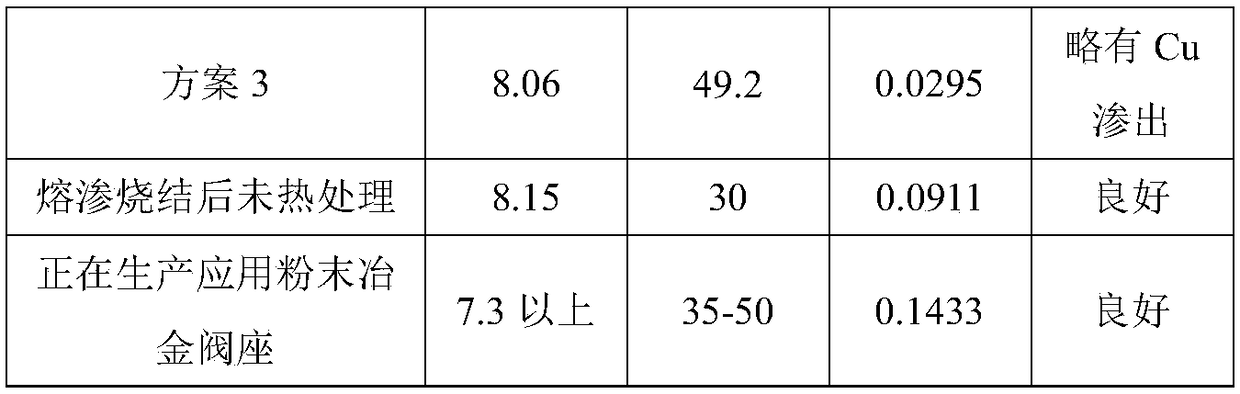

[0047] Abrasion resistance test. Test conditions: The wear test is carried out on the M-2000 friction and wear testing machine, using disc-pin wear, resin alumina material as the abrasive, the load is 120N, the friction speed is 200r / min, and the wear time is 30min.

[0048] The specific index of the powder metallurgy high-speed steel valve seat prepared by the technical solution of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com