A kind of polypropylene composite material and its preparation method and application

A composite material and polypropylene technology, applied in the field of polypropylene composite materials and its preparation, can solve the problems of poor gasoline resistance and achieve excellent injection molding performance, strong operability and normal appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

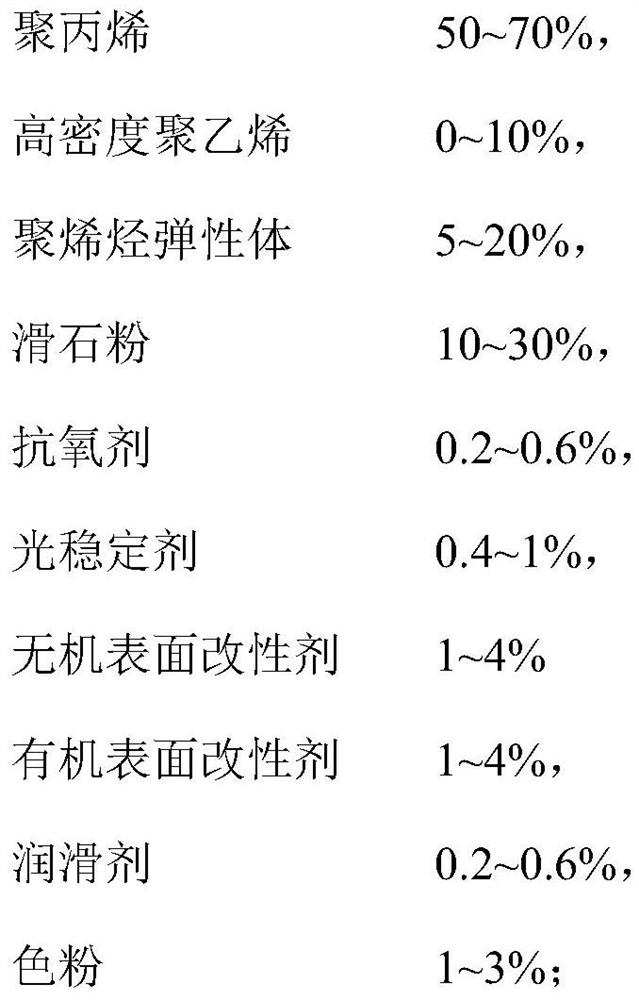

Method used

Image

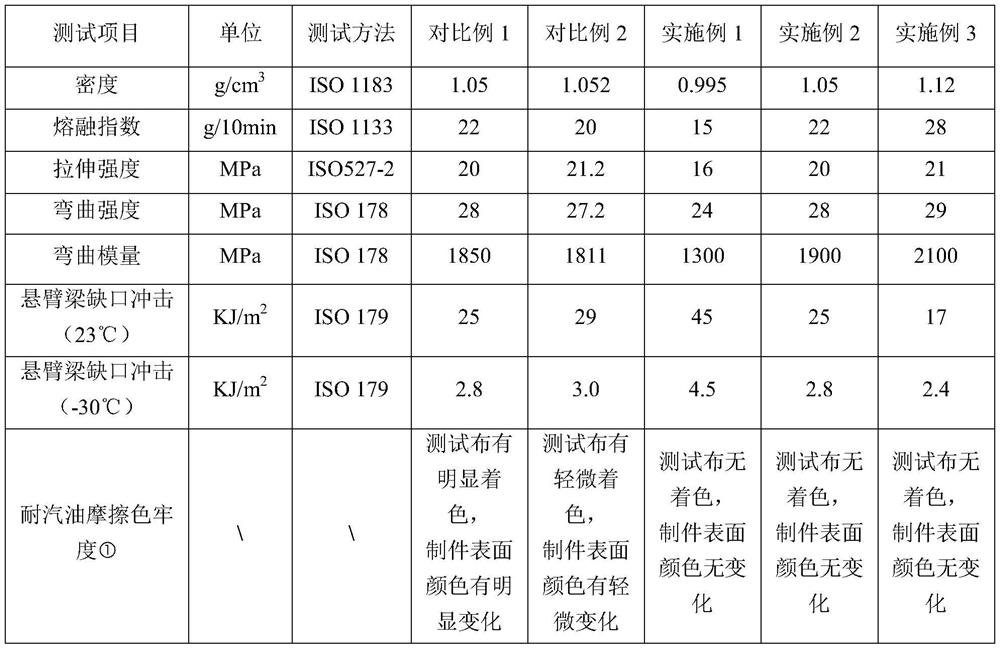

Examples

Embodiment 1

[0041] The preparation method of composite material in the present embodiment is:

[0042] (1) Polypropylene, high-density polyethylene, polyolefin elastomer, talcum powder, antioxidant, light stabilizer, inorganic surface modifier, organic surface modifier, lubricant, The toner is mixed evenly at high speed to make a mixed material;

[0043] (2) Put the mixed material into a twin-screw extruder to obtain a polypropylene composite material through melting, extrusion, granulation, and drying, wherein the barrel temperature of the twin-screw extruder is 200° C., and the screw speed is 500r / min, the vacuum degree is -0.06MPa.

[0044]Among them, the polypropylene used is BX-3920, the high-density polyethylene is HDPE8008, the polyolefin elastomer is EPDM, the antioxidant is antioxidant 1010 and antioxidant 168, the light stabilizer is light stabilizer 622, and the inorganic surface The modifying agent is montmorillonite grafted with maleic anhydride, the organic surface modifyi...

Embodiment 2

[0046] The preparation method of composite material in the present embodiment is:

[0047] (1) Polypropylene, high-density polyethylene, polyolefin elastomer, talcum powder, antioxidant, light stabilizer, inorganic surface modifier, organic surface modifier, lubricant, The toner is mixed evenly at high speed to make a mixed material;

[0048] (2) Put the mixed material into a twin-screw extruder to obtain a polypropylene composite material through melting, extrusion, granulation, and drying, wherein the barrel temperature of the twin-screw extruder is 190° C., and the screw speed is 300r / min, the vacuum degree is -0.04MPa.

[0049] Among them, the polypropylene used is BX-3920 and M60RHC, the high-density polyethylene is HDPE8008, the polyolefin elastomer is POE8730, the antioxidant is antioxidant 1010 and antioxidant 168, the light stabilizer is 3808PP5, and the organic surface modification The neutralizer is maleic anhydride grafted montmorillonite, and the lubricant is ca...

Embodiment 3

[0051] The preparation method of composite material in the present embodiment is:

[0052] (1) Polypropylene, high-density polyethylene, polyolefin elastomer, talcum powder, antioxidant, light stabilizer, inorganic surface modifier, organic surface modifier, lubricant, The toner is mixed evenly at high speed to make a mixed material;

[0053] (2) Add the mixed materials into a twin-screw extruder to obtain a polypropylene composite material through melting, extrusion, granulation, and drying, wherein the barrel temperature of the twin-screw extruder is 220° C., and the screw speed is 400r / min, the vacuum degree is -0.1MPa.

[0054] Among them, the polypropylene used is M60RHC, the high-density polyethylene is HDPE8008, the polyolefin elastomer HDPE, the antioxidant is antioxidant 1010 and antioxidant 168, the light stabilizer is 3808PP5, and the inorganic surface modifier is Malay Acid anhydride grafted montmorillonite, organic surface modifier is maleic anhydride grafted po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com