Solvent-free resin composition for vacuum impregnation

A solvent-free resin, vacuum impregnation technology, applied in the field of solvent-free impregnating resin, high-voltage motor vacuum pressure impregnation with solvent-free impregnating resin, can solve the problems of high toxicity and volatility, and achieve high curing degree, slow viscosity growth, expansion rate small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

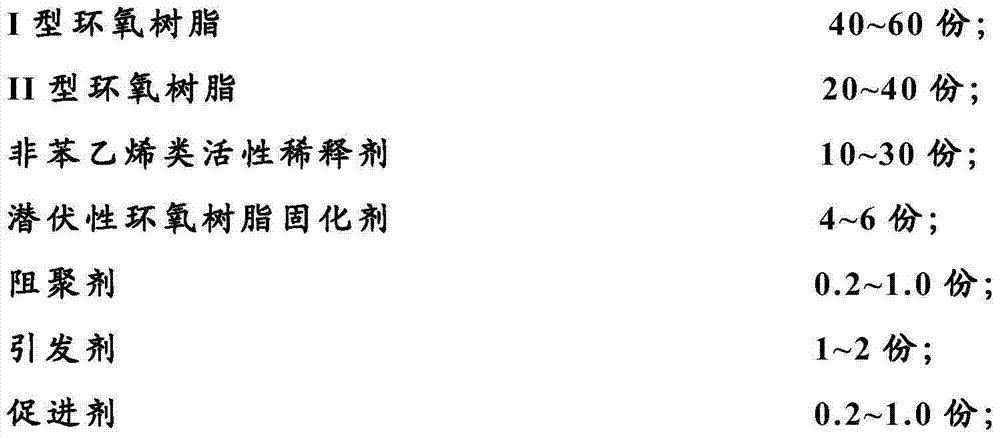

[0036] A solvent-free resin composition for vacuum impregnation, the raw material formula is as follows:

[0037]Resin components: 30 parts molecular distillation low viscosity bisphenol A epoxy resin (DER332, 4000-6000mPas), 10 parts low viscosity bisphenol F epoxy resin (DER354, 3500-5700mPas), 20 parts hydrogenated bisphenol A epoxy Resin (EPALLOY5000, 1300-2500mPas), 10 parts of ethylene glycol diglycidyl ether, 10 parts of bisglycidyl ether;

[0038] Reactive diluent: 10 parts of glycidyl methacrylate, 10 parts of 2-vinylphenyl glycidyl ether;

[0039] Curing agent: 4 parts 2E4MZ-CN;

[0040] Inhibitor: 0.2 parts of hydroquinone;

[0041] Initiator: 1 part dicumyl peroxide;

[0042] Accelerator: 0.2 parts of aluminum acetylacetonate.

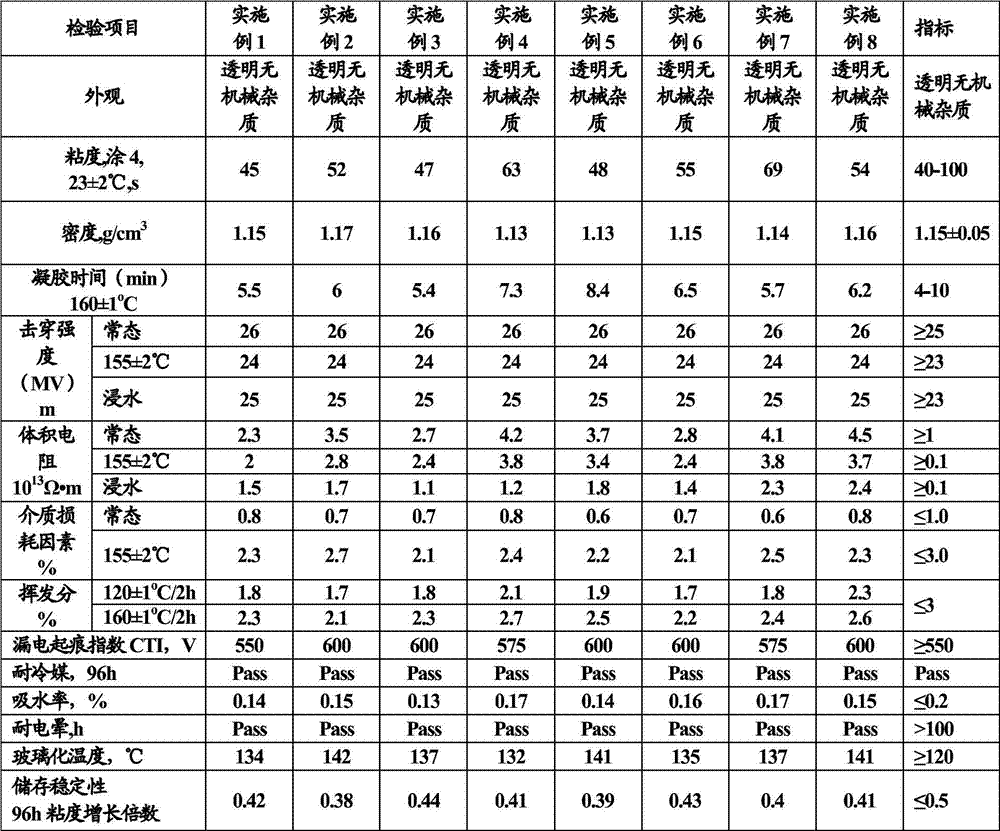

[0043] Before use, the above-mentioned raw materials were accurately weighed and thoroughly mixed uniformly to form a solvent-free resin composition for vacuum impregnation, and its performance parameters are shown in Table 1.

Embodiment 2

[0045] A solvent-free resin composition for vacuum impregnation, the raw material formula is as follows:

[0046] Resin components: 20 parts of molecular distillation low viscosity bisphenol A epoxy resin (DER332, 4000-6000mPas), 20 parts of low viscosity bisphenol F epoxy resin (DER354, 3500-5700mPas), 10 parts of low viscosity novolac epoxy Resin (DEN431, 1100-1700mPas), 10 parts of ethylene glycol diglycidyl ether, 10 parts of glycerin epoxy resin;

[0047] Reactive diluent: 10 parts of allyl glycidyl ether, 10 parts of 2-vinylphenyl glycidyl ether, 10 parts of 4-methyl 2-ethylphenyl glycidyl ether;

[0048] Curing agent: 5.2 parts of 2E4MZ-CN;

[0049] Inhibitor: 0.4 part p-benzoquinone;

[0050] Initiator: 2 parts of di-tert-butyl peroxide;

[0051] Accelerator: 1 part chromium acetylacetonate.

[0052] Before use, the above-mentioned raw materials were thoroughly mixed evenly to form a solvent-free resin composition for vacuum impregnation, and its performance parame...

Embodiment 3

[0054] A solvent-free resin composition for vacuum impregnation, the raw material formula is as follows:

[0055] Resin components: 30 parts molecular distillation low viscosity bisphenol A epoxy resin (DER332, 4000-6000mPas), 10 parts low viscosity novolac epoxy resin (DEN431, 1100-1700mPas), 10 parts hydrogenated bisphenol A epoxy resin (EPALLOY5000, 1300-2500mPas), 10 parts of bisglycidyl ether, 10 parts of resorcinol bisglycidyl ether;

[0056] Reactive diluent: 10 parts glycidyl methacrylate, 10 parts allyl glycidyl ether, 10 parts diallyl bisphenol A glycidyl ether;

[0057] Curing agent: 4.8 parts of 2E4MZ-CN;

[0058] Inhibitor: 0.6 parts of tert-butylhydroquinone;

[0059] Initiator: 1 part of tert-butylperoxycumene;

[0060] Accelerator: 0.8 parts of aluminum acetylacetonate.

[0061] Before use, the above-mentioned raw materials were thoroughly mixed evenly to form a solvent-free resin composition for vacuum impregnation, and its performance parameters are shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com