Step-by-step low-temperature carbonization system of brown coal

A step-by-step, air inlet system technology, applied in special forms of dry distillation, direct heating dry distillation, petroleum industry, etc., can solve the problems of poor environmental protection, many impurities, large amount of waste water, etc., and achieve good stability and high calorific value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

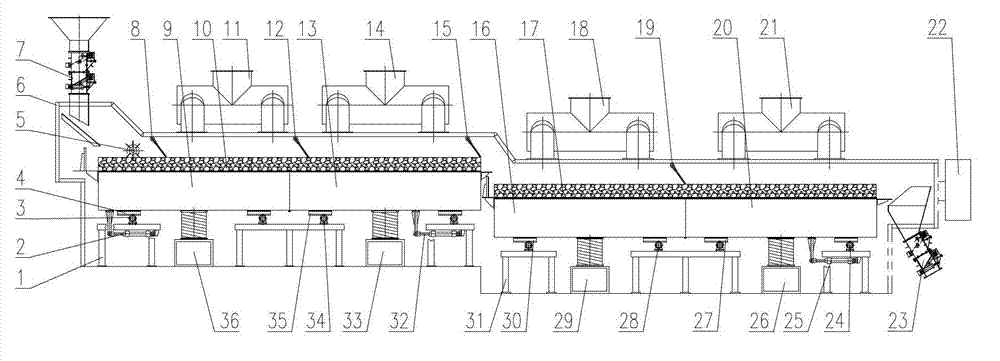

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] Referring to the accompanying drawings, a step-by-step lignite low-temperature carbonization system includes a shell 6. The interior of the shell 6 is divided into a drying section, a dry distillation section, a waste heat recovery section, and a cooling section that communicate with each other. The front end of the shell 6 is equipped with a feeding device 7. The coal material 10 enters the interior of the casing 6 through the feeding device 7 and falls onto the conveying assembly 9 of the drying section. The pneumatic system of the feeding device 7 can be adjusted to adjust the feeding amount, and the feeding device 7 also has a feeding sealing function, which can prevent the gas inside the casing 6 from overflowing and the outside air from entering.

[0025] The drying section is equipped with a drying section conveying assembly 9, and the drying section conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com