Efficient two-phase anaerobic fermentation device

An anaerobic fermentation and high-efficiency technology, which is applied in biochemical instruments, biological sludge treatment, waste fuel, etc., can solve the problems of reduced degree of phase separation in the reactor, low substrate degradation rate, and limited biogas production, and achieves a reasonable structure. , to ensure continuous and stable operation, to avoid the effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

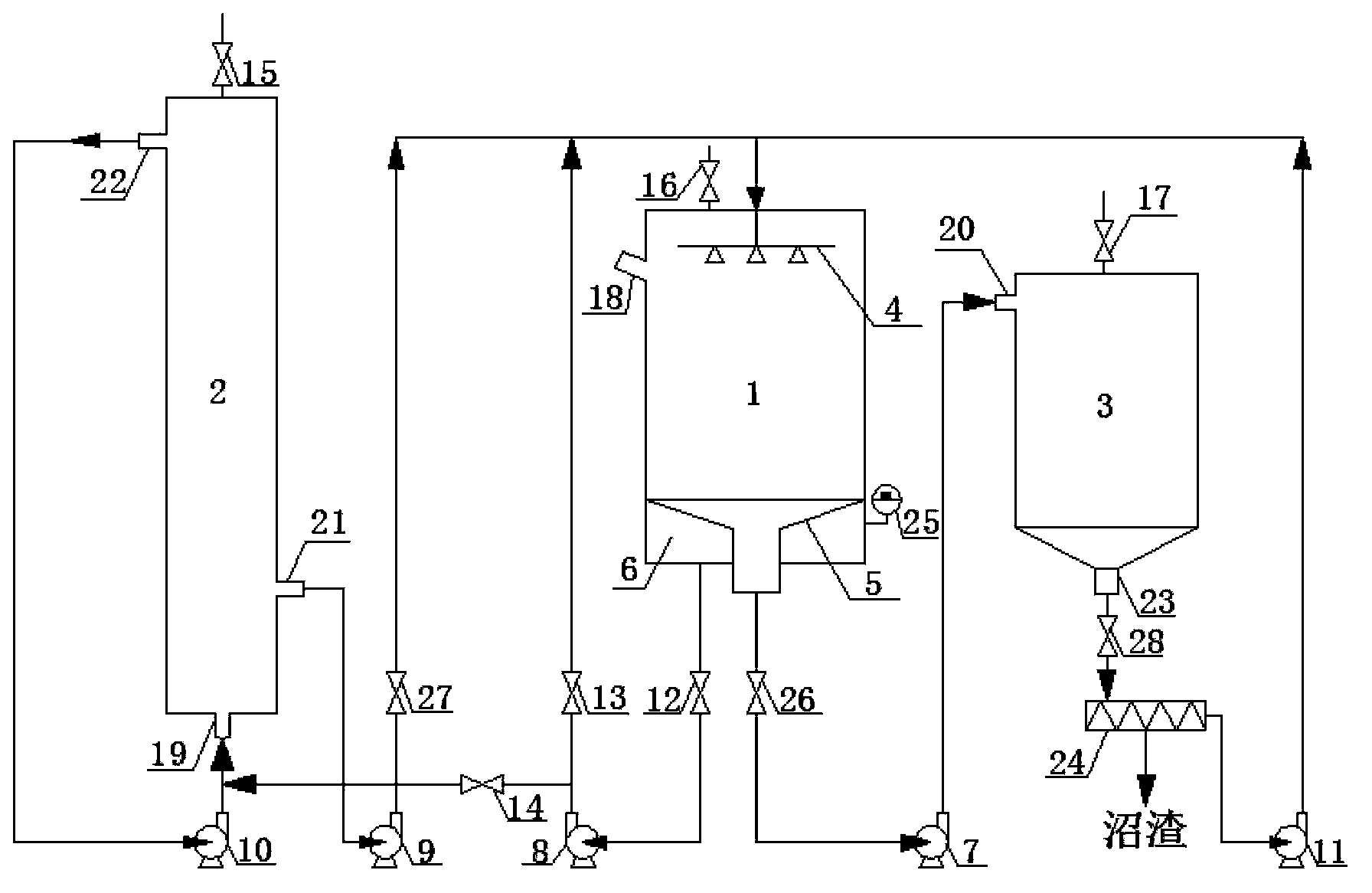

[0026] like figure 1 As shown, a high-efficiency two-phase anaerobic fermentation device includes a hydrolysis acid production reactor 1, a high-temperature hydrolysis device 3, and at least one methane production reactor 2;

[0027] The top of the hydrolysis acid production reactor 1 is provided with a biogas collection port 16 of the hydrolysis acid production device, and the upper part of the side is provided with a hydrolysis acid production reactor feed port 18; the top of the hydrolysis acid production reactor is provided with a rotary nozzle 4, so that The middle and lower part of the hydrolysis acid production reactor is provided with a conical support 5, and the airtight cavity formed between the conical support 5 and the bottom of the hydrolysis acid production reactor 1 is the permeate storage chamber 6, and the side of the permeate storage chamber 6 is Set level gauge 25.

[0028] The side of the high-temperature hydrolysis device 3 is provided with a high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com