Preparation method of back passivated crystalline silicon solar cell

A solar cell and backside passivation technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems that are not suitable for large-scale production, silicon wafers are easily polluted, and the process flow is too many, so as to improve the conversion efficiency of cells and save energy. Process time, avoid process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A method for preparing a backside passivated crystalline silicon solar cell, comprising the following steps:

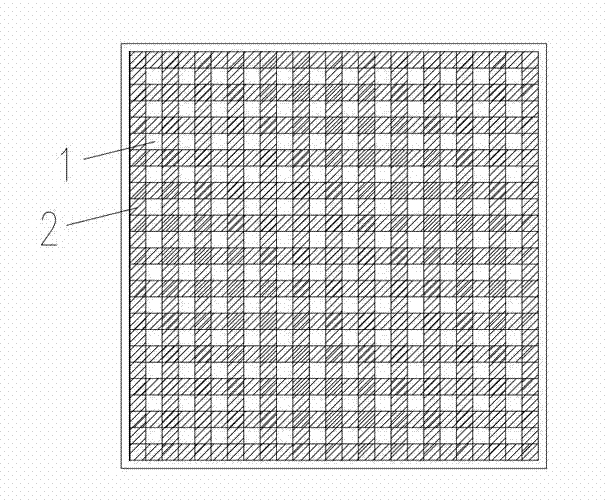

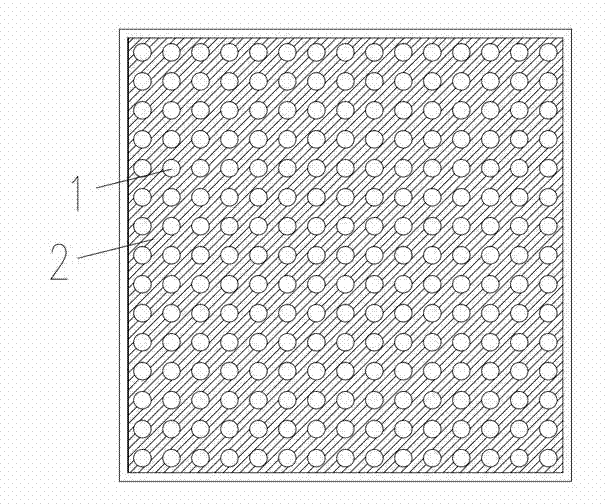

[0021] (1) Process the graphite baffle in the graphite boat to form a hollowed-out mesh structure;

[0022] (2) Put the silicon wafer in the silicon wafer flower basket and wait for coating after texturing, diffusion to make PN junction, peripheral etching, and removal of phospho-silicate glass; the steps described in this step are all existing technologies, and will not be expanded here in detail .

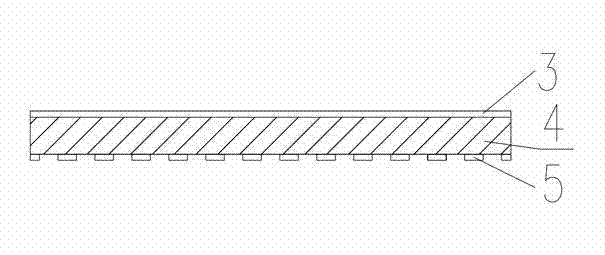

[0023] (3) Put the silicon wafer processed in step (2) into the graphite boat processed in step (1), so that the back of the silicon wafer is close to the graphite baffle, and use the coating equipment to cover the unobstructed area and the front of the silicon wafer At the same time, a silicon nitride film is deposited. The coating equipment is also called PECVD equipment.

[0024] (4) Screen-print the back electrode, back electric field and front electrode on...

specific Embodiment 1

[0026] Specific embodiment one: a kind of preparation method of rear passivation crystalline silicon solar cell, comprises the following steps:

[0027] (1) Process the graphite baffle in the graphite boat to form a figure 1 In the network structure shown, the hollow part is a square with a side length of 6mm, and a total of 144 squares are evenly arranged on the graphite baffle. Then put the graphite baffle into the graphite boat and fix it;

[0028] (2) After the silicon wafer is textured, diffused to make a PN junction, the periphery is etched, and the phospho-silicate glass is removed, it is placed in a silicon wafer flower basket and waits for coating;

[0029] (3) Put the silicon wafer processed in step (2) in the graphite boat, so that the back of the silicon wafer is close to the graphite baffle, and use PECVD equipment to coat the silicon nitride film on the front and back of the silicon wafer at the same time;

[0030] (4) Screen-print the back electrode, back elec...

specific Embodiment 2

[0031] Specific embodiment two: a kind of preparation method of rear passivation crystalline silicon solar cell, comprises the following steps:

[0032] (1) Process the graphite baffle in the graphite boat to form a figure 2 In the network structure shown, the hollow part is a circle with a diameter of 6 mm, and a total of 225 circles are evenly arranged on the graphite baffle. Then put the graphite baffle into the graphite boat and fix it;

[0033] (2) After the silicon wafer is textured, diffused to make a PN junction, the periphery is etched, and the phospho-silicate glass is removed, it is placed in a silicon wafer flower basket and waits for coating;

[0034] (3) Put the silicon wafer processed in step (2) in the graphite boat, so that the back of the silicon wafer is close to the graphite baffle, and use PECVD equipment to coat the silicon nitride film on the front and back of the silicon wafer at the same time;

[0035] (4) Screen-print the back electrode, the back e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com