Preparation device of isobutyl vinyl ether and preparation method thereof

A technology for isobutyl vinyl ether and preparation equipment, which is applied in ether preparation, ether preparation by addition of unsaturated compounds, organic chemistry, etc., and can solve the problems of high reactor manufacturing cost, low gas-liquid mass transfer efficiency, and poor safety and reliability and other problems, to achieve the effect of simple structure, avoiding amplification effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

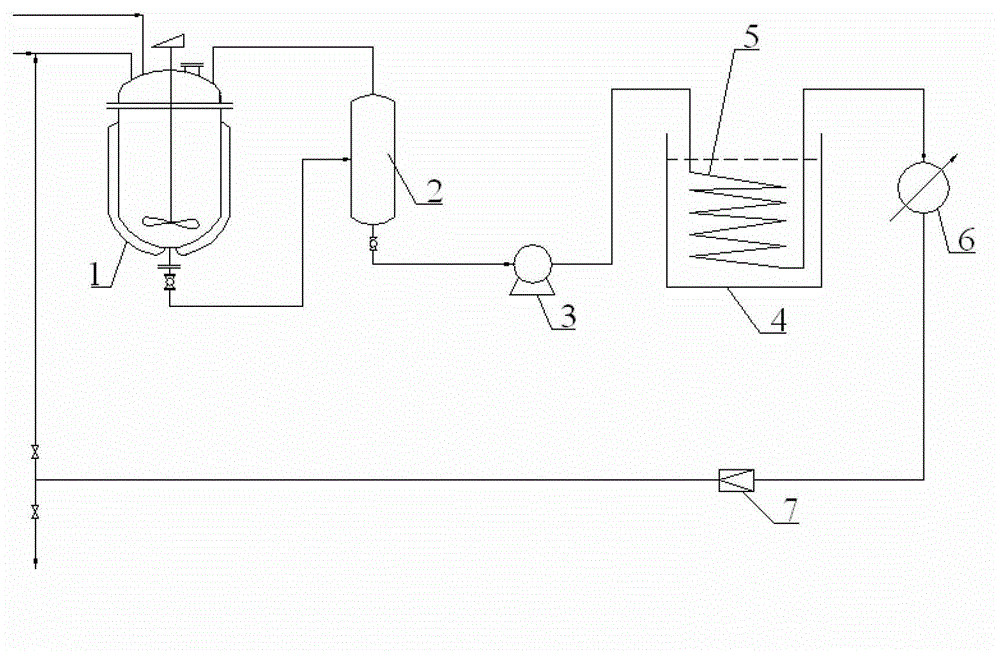

[0026] The reaction of acetylene and isobutanol uses figure 1 The shown circulation reaction device is composed of absorber 1, gas-liquid separator 2, metering pump 3, constant temperature oil bath 4, tubular reactor 5, condenser 6 and pressure reducing valve 7, etc. The tubular reactor 5 is a stainless steel tube with an inner diameter of 2 mm and a length of 32 m, and the volume of the reactor is about 100 ml. The process operating conditions are as follows:

[0027] Catalyst dosage: 1.5% of the total mass of isobutanol;

[0028] Feed flow: 200g / h;

[0029] Absorber temperature: 25°C;

[0030] Absorber pressure: 0.105MPa;

[0031] Reactor temperature: 150°C;

[0032] Reactor pressure: 4MPa;

[0033] Circulation rate: 3.6L / h.

[0034] After about 3 hours of operation, the cyclic reaction system reached a steady state. The discharge rate of the reaction product was 241 g / h, the conversion rate of isobutanol was 65%, and the selectivity of the reaction to isobutyl vinyl...

Embodiment 2

[0036] The reaction of acetylene and isobutanol uses figure 1 The cyclic reaction apparatus shown. The tubular reactor is a stainless steel tube with an inner diameter of 2mm and a length of 32m. The reactor volume is about 100ml. The process operating conditions are as follows:

[0037] Catalyst dosage: 2% of the total mass of isobutanol;

[0038] Feed flow: 200g / h;

[0039] Absorber temperature: 25°C;

[0040] Absorber pressure: 0.105MPa;

[0041] Reactor temperature: 160°C;

[0042] Reactor pressure: 4MPa;

[0043] Circulation rate: 3.6L / h.

[0044] After 3 hours of operation, the cyclic reaction system reached a steady state. The discharge rate of the reaction product was 248g / h, the conversion rate of isobutanol was 75%, and the selectivity of the reaction to isobutyl vinyl ether was 96.5%.

Embodiment 3

[0046] The reaction of acetylene and isobutanol uses figure 1 The cyclic reaction apparatus shown. The tubular reactor is a stainless steel tube with an inner diameter of 2mm and a length of 32m, and the volume of the reactor is about 100ml. The process operating conditions are as follows:

[0047] Catalyst content: 1% of the total mass of isobutanol;

[0048] Feed flow: 200g / h;

[0049] Absorber temperature: 15°C;

[0050] Absorber pressure: 0.105MPa;

[0051] Reactor temperature: 140°C;

[0052] Reactor pressure: 3MPa;

[0053] Circulation rate: 3.6L / h.

[0054] After 3 hours of operation, the cyclic reaction system reached a steady state. The discharge rate of the reaction product was 231 g / h, the conversion rate of isobutanol was 55%, and the selectivity of the reaction to isobutyl vinyl ether was 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com