Starch-containing biodegradable barrier-property film as well as preparation method and application thereof

A biodegradable and barrier technology, used in biological packaging, flexible covering, transportation and packaging, etc., can solve the problems of difficult degradation, difficult recycling, and the lack of barrier properties of biodegradable materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

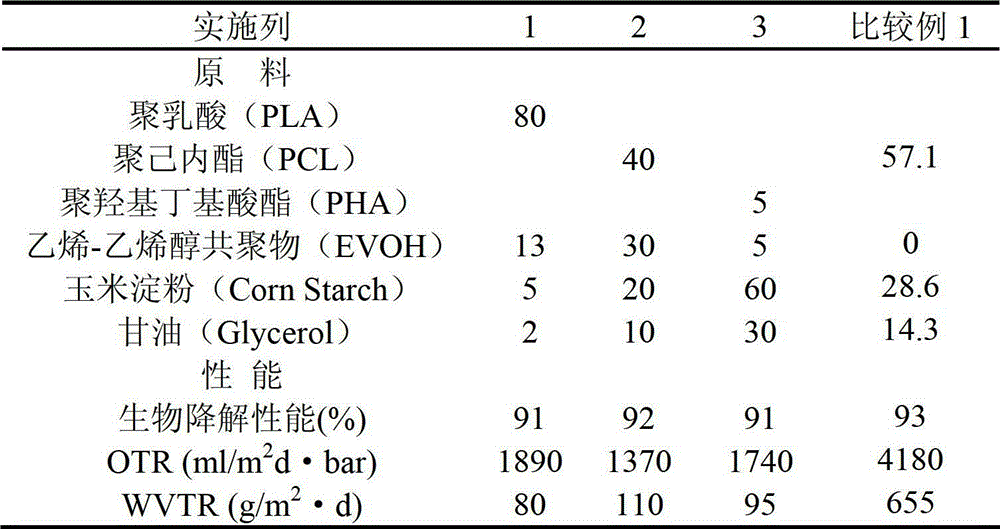

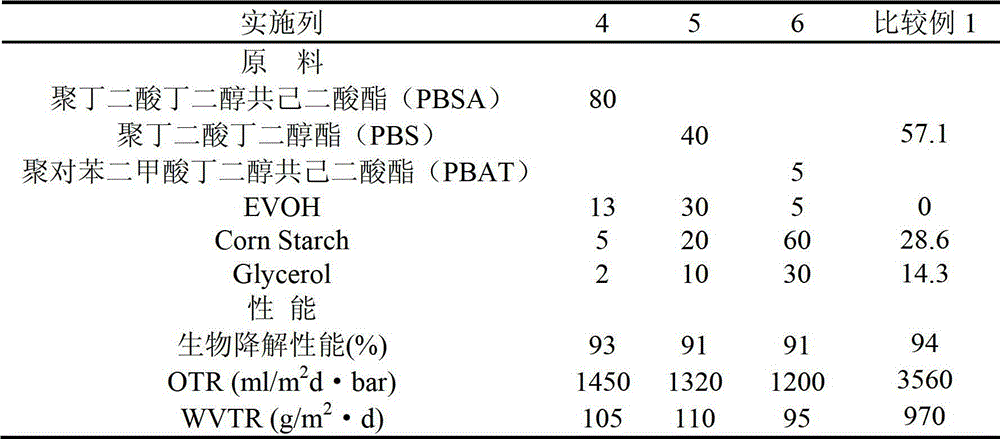

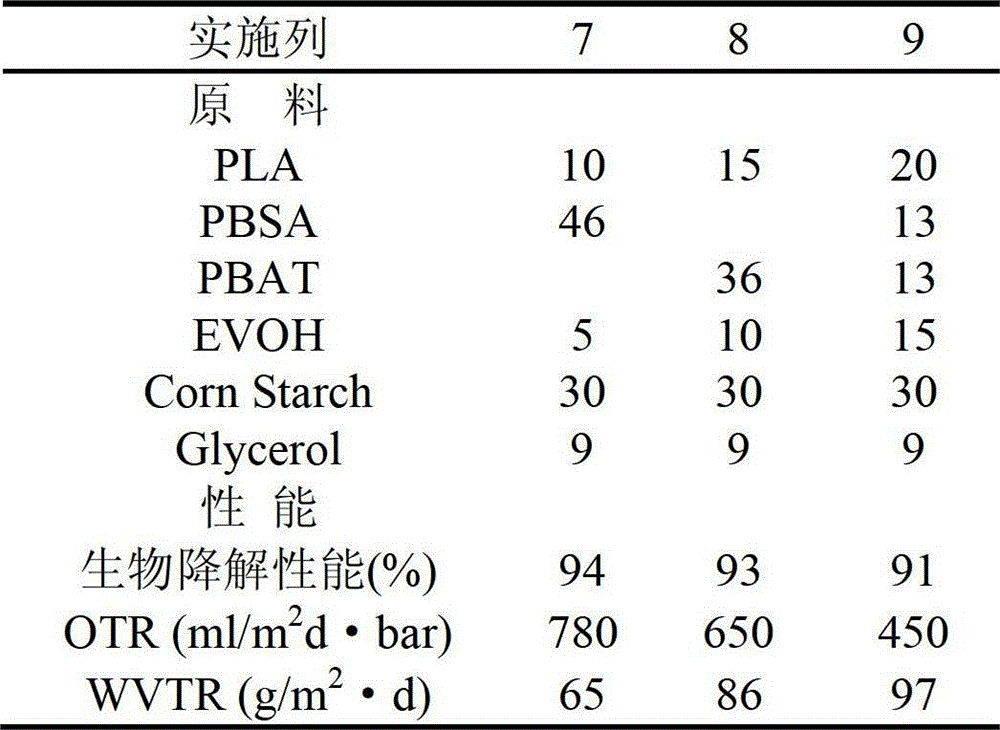

[0037] A starch-containing biodegradable barrier film, the raw materials of which are shown in Table 1-3 (in Table 1-3, the unit of the amount of raw materials is mass percentage), and its preparation method includes the following steps:

[0038] (1) Dry each raw material in an oven at 80°C for 5 hours;

[0039] (2) Add the dried raw materials into the high mixer, first stir at low speed for 5 minutes, then stir at high speed for 3 minutes;

[0040] (3) Put the uniformly mixed materials into the twin-screw extruder. The diameter of the extruder is 40mm, the ratio of length to diameter is 36:1, and there are 9 heating zones and a vacuum exhaust device. The extrusion process selects the following operating conditions:

[0041] Temperature setting: 80 / 150 / 190 / 190 / 190 / 190 / 190 / 190 / 170℃

[0042] Feeding speed: 100kg / h

[0043] Screw speed: 300rpm

[0044] Vacuum pressure: 0.4 atmosphere;

[0045] After the strips of the extruder are made into granules by underwater hot cutting,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com