Catalytic hydrogenation method and catalytic hydrogenation apparatus for coal tar

A technology for catalytic hydrogenation and coal tar, applied in the field of coal chemical industry, can solve problems such as increased processing cost, environmental damage, and reduced yield of final products, and achieves the effects of saving equipment investment, prolonging the start-up period, and reducing operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

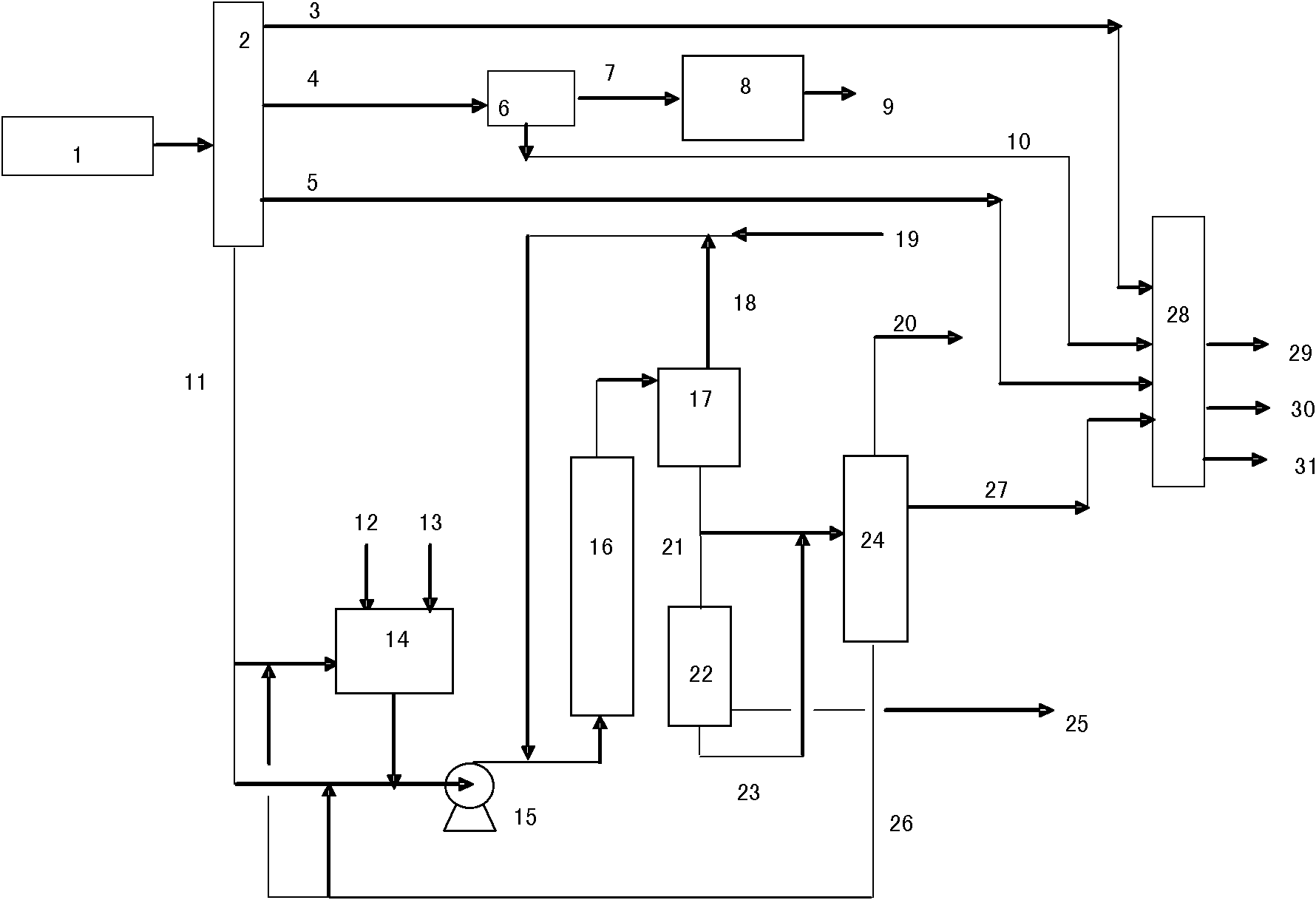

Method used

Image

Examples

preparation example Construction

[0038] Preparation of catalyst oil slurry. The function of the catalyst oil slurry is to add an appropriate amount of catalyst 12 and additive 13 to the heavy oil fraction to prepare for catalytic hydrocracking reaction. There are three ways to prepare catalyst slurry. The first way is to separate a small part from the heavy oil fraction 11, and add catalyst and additives to this part of the heavy oil fraction; the second way is to add catalysts and additives to all or part of the circulating tail oil. The third way is to separate a small part from the heavy oil fraction and mix it with all or part of the circulating tail oil and add catalysts and additives; then fully mix under normal pressure and temperature conditions of 80°C-200°C to make catalyst oil slurry. The weight percentage of solid matter in the catalyst oil slurry is 20-45%, preferably 25-40%.

[0039] Mix the catalyst oil slurry with the remaining heavy oil fraction (if the catalyst oil slurry obtained by way two...

example 1

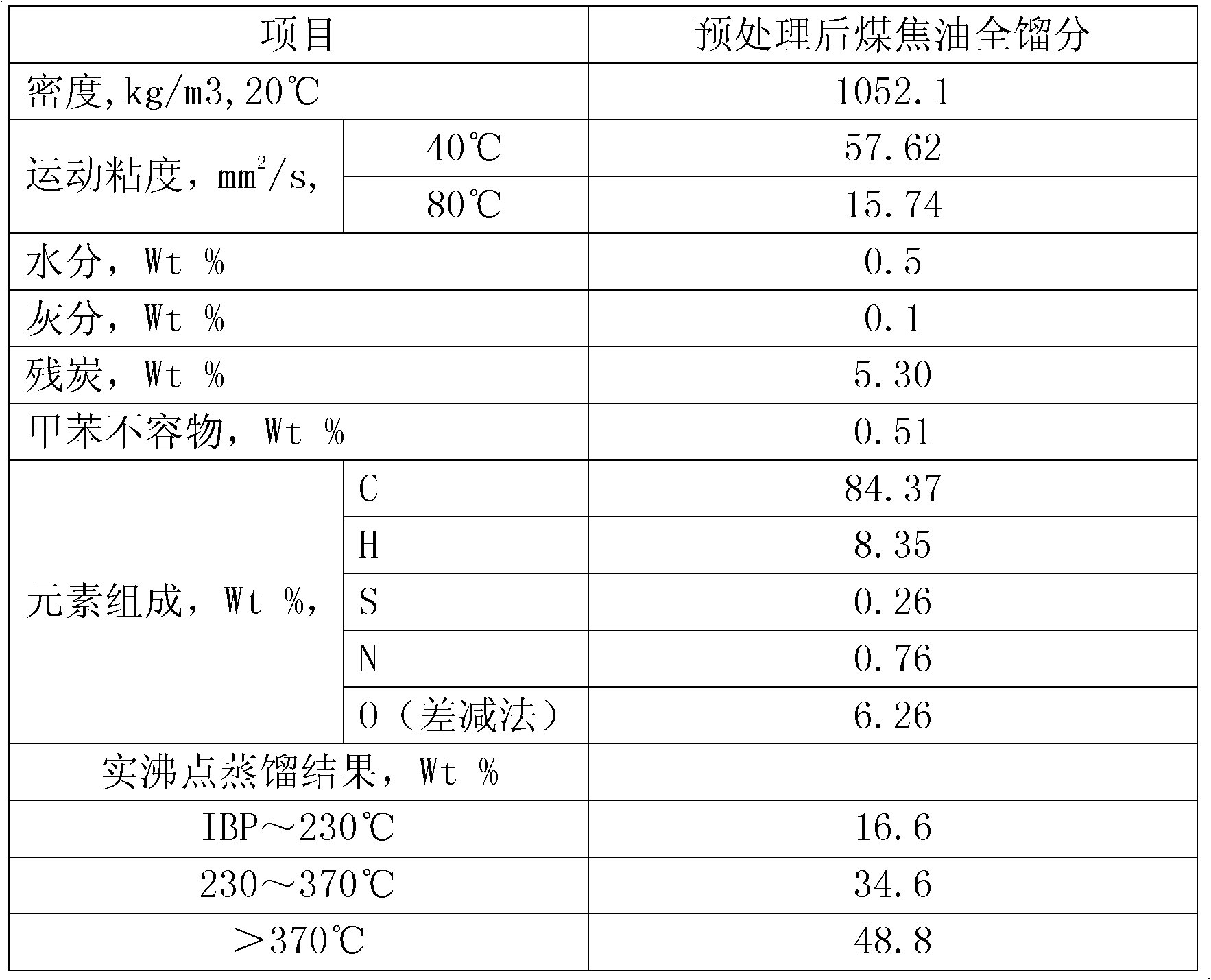

[0047] Select a kind of typical coal tar as test raw material, test scale is 100.0 kilograms of coal tar / day, carry out pretreatment and distillation according to step 1, product situation is as shown in the following table:

[0048]

[0049] The pretreated coal tar is distilled and separated into IBP~230°C, 230~370°C and heavy fractions greater than 370°C, and the heavy fractions greater than 370°C are used as the raw material of the suspended bed hydrogenation reactor for lightening reaction.

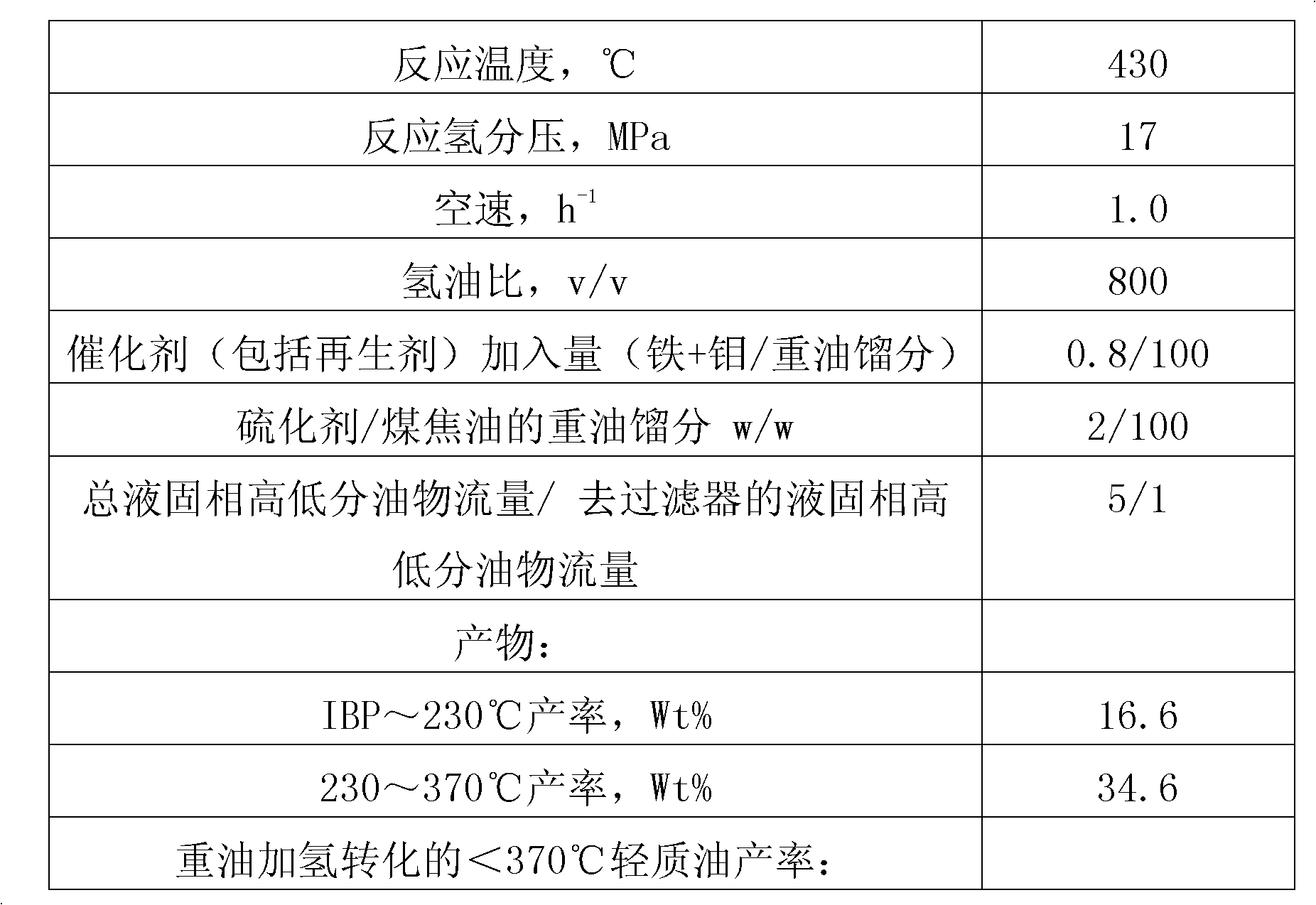

[0050] According to the above-mentioned step 2, a small part of the circulating tail oil and a small part of the heavy oil fraction are prepared together with the catalyst and the vulcanizing agent under the stirring condition of 80 ℃ to prepare the catalyst oil slurry, and the solid concentration of the catalyst oil slurry is about 25%. . The catalyst used is a powdered molybdenum-iron composite catalyst with a particle size of less than 100 μm, and molybdenum: iron is equal to 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com