Method for detecting washed surface of optical substrate used for laser thin film element

A technology for surface detection and substrate detection, applied in color/spectral characteristic measurement, measuring devices, scientific instruments, etc., can solve problems affecting component damage thresholds, surface scratches, pitting, etc., and achieve intuitive detection results and high detection accuracy Effects of high and high damage thresholds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Detection after cleaning with BK7 optical substrate:

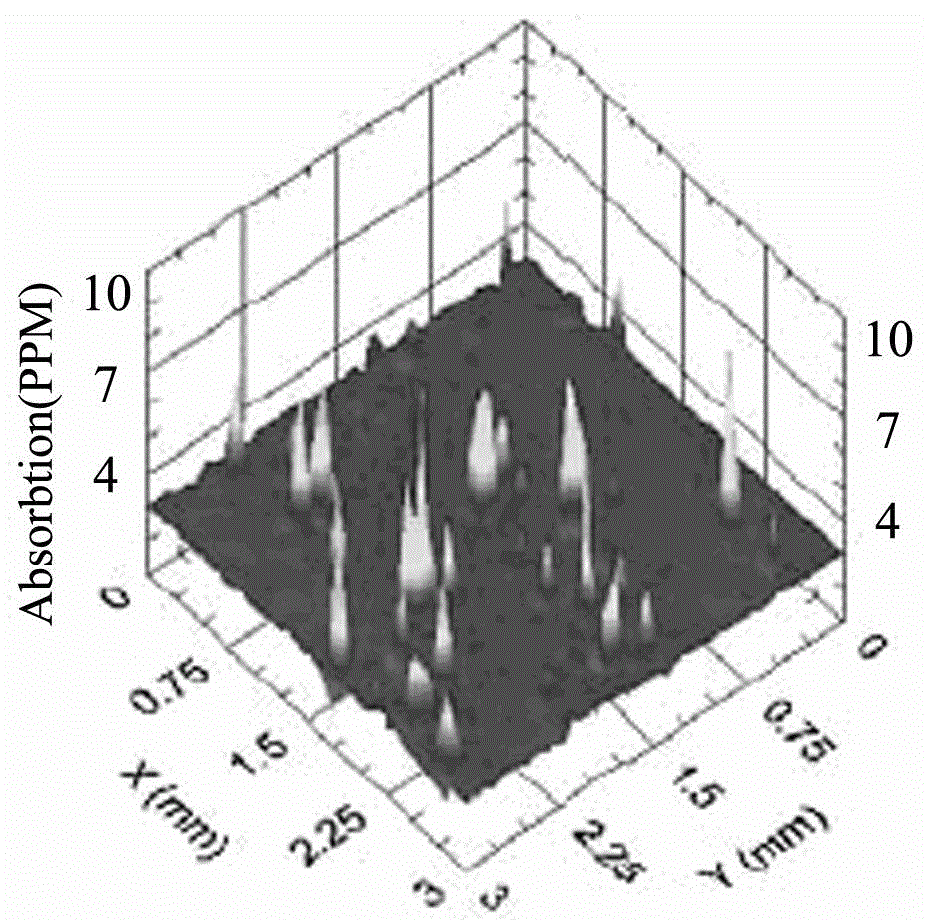

[0024] Spin-coat small balls with uniform size of 10 μm and 5 μm on a clean φ30mm fused silica optical substrate, and control the distribution density of the small balls at 10-20 pieces / mm 2 , as a standard film after drying. Use a bright field microscope with a magnification of 50 times to calibrate the size and distribution density of the beads, as shown in the attached Figure 1 shown. Before starting to inspect the substrate, turn on the white light surface detection lamp, and after 5 minutes of warm-up, use 10 μm, 5 μm balls to observe under the detection lamp to confirm that the beads adsorbed on the substrate surface can be seen, and the scales of the two can be distinguished , so as to confirm that the visibility state of the detection lamp is normal, and the particle detection of the cleaned optical substrate can be started.

[0025] During the substrate detection process, when the inspector observes the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical damage threshold | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com