Method for manufacturing flexible pyramid array GaN-based semiconductor light-emitting diode

A technology of light-emitting diodes and pyramids, which is applied to semiconductor devices, electrical components, circuits, etc., and can solve problems such as reliability aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The key of the present invention is to wet-etch the stripped nitrogen-polar GaN layer into a separated micron-scale pyramid vertical structure LED array, separate the prepared graphene from the mother substrate, and deposit it on the pyramid-etched vertical structure LED array. On, a transparent conductive film is formed. The flexible split pyramid array vertical structure LED produced by this method can effectively improve the light efficiency of the LED and reduce the reverse leakage current of the LED. The manufactured LED device can be bent within a certain mechanical strength without any impact on the entire device structure, making flexible LED devices possible.

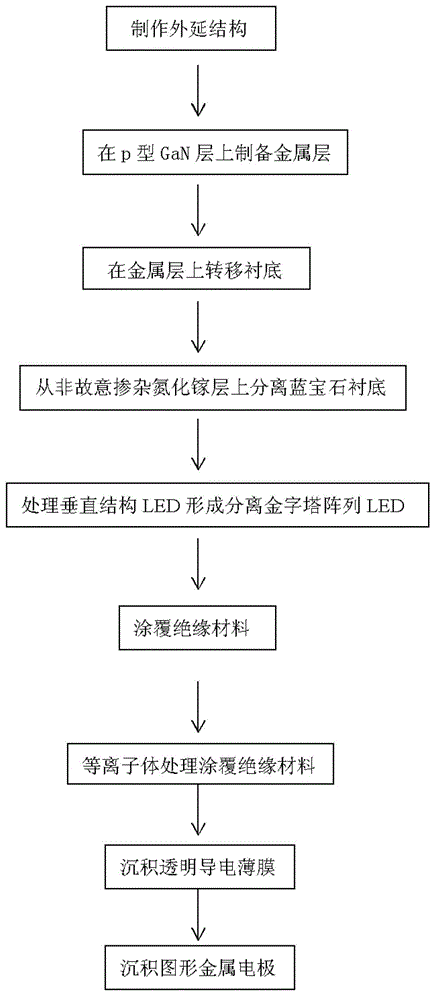

[0022] see Figure 1-Figure 6 As shown, the present invention provides a kind of method of making flexible pyramid array GaN-based semiconductor light-emitting diode, comprising:

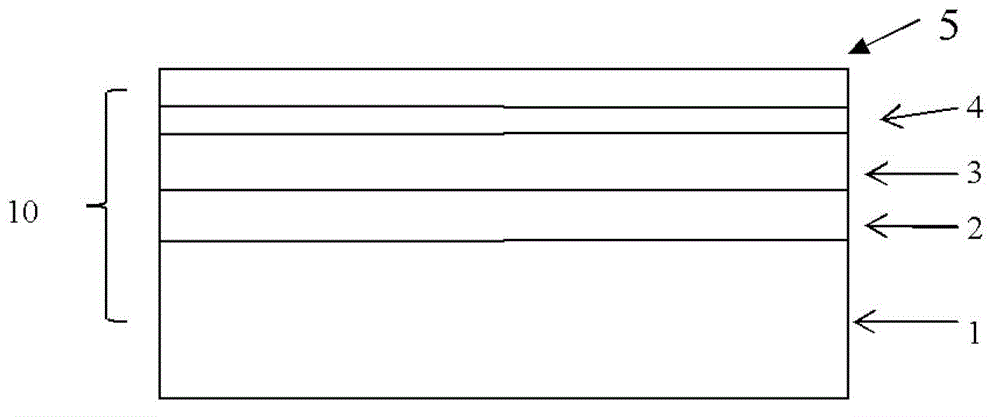

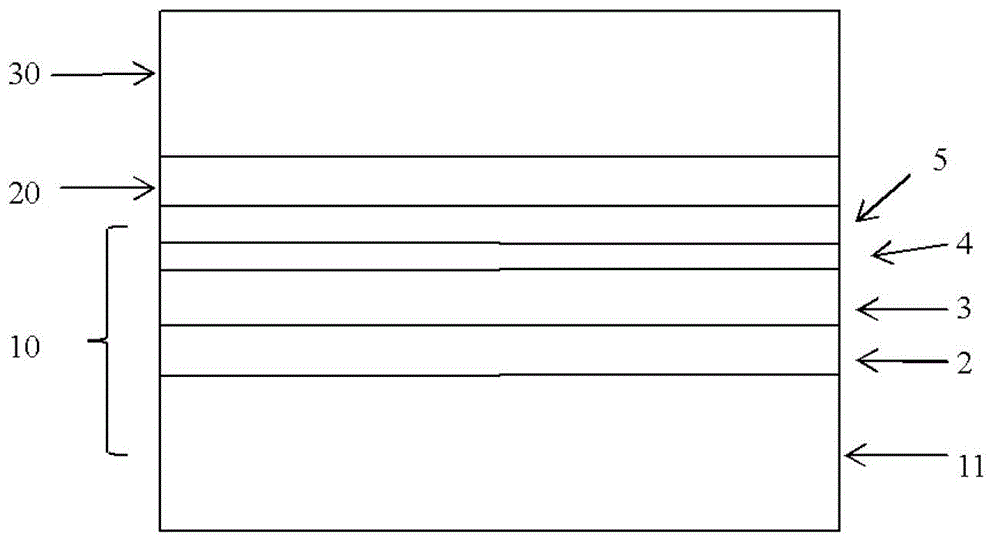

[0023] Step 1: Select an LED epitaxial structure 10 (see figure 2 ), including a sapphire substrate 1 and an unintention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com