Method for synthesizing light aromatic hydrocarbon and liquefied petroleum gas from low carbon number oxygen-containing compound mixed raw material

A technology of liquefied petroleum gas and mixed raw materials, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, petroleum industry, fuel, etc., to achieve the effect of simple preparation method and reduced dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

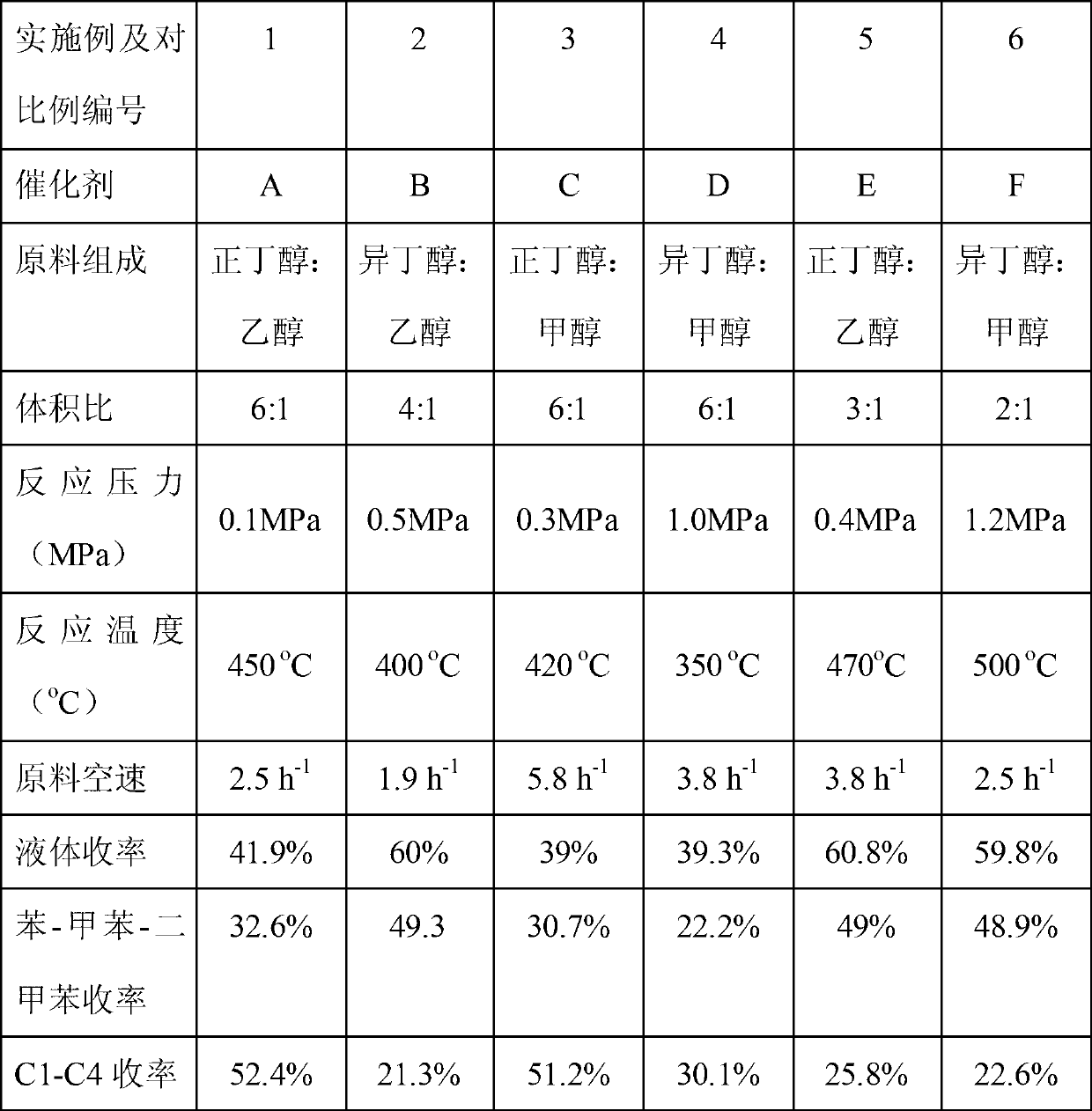

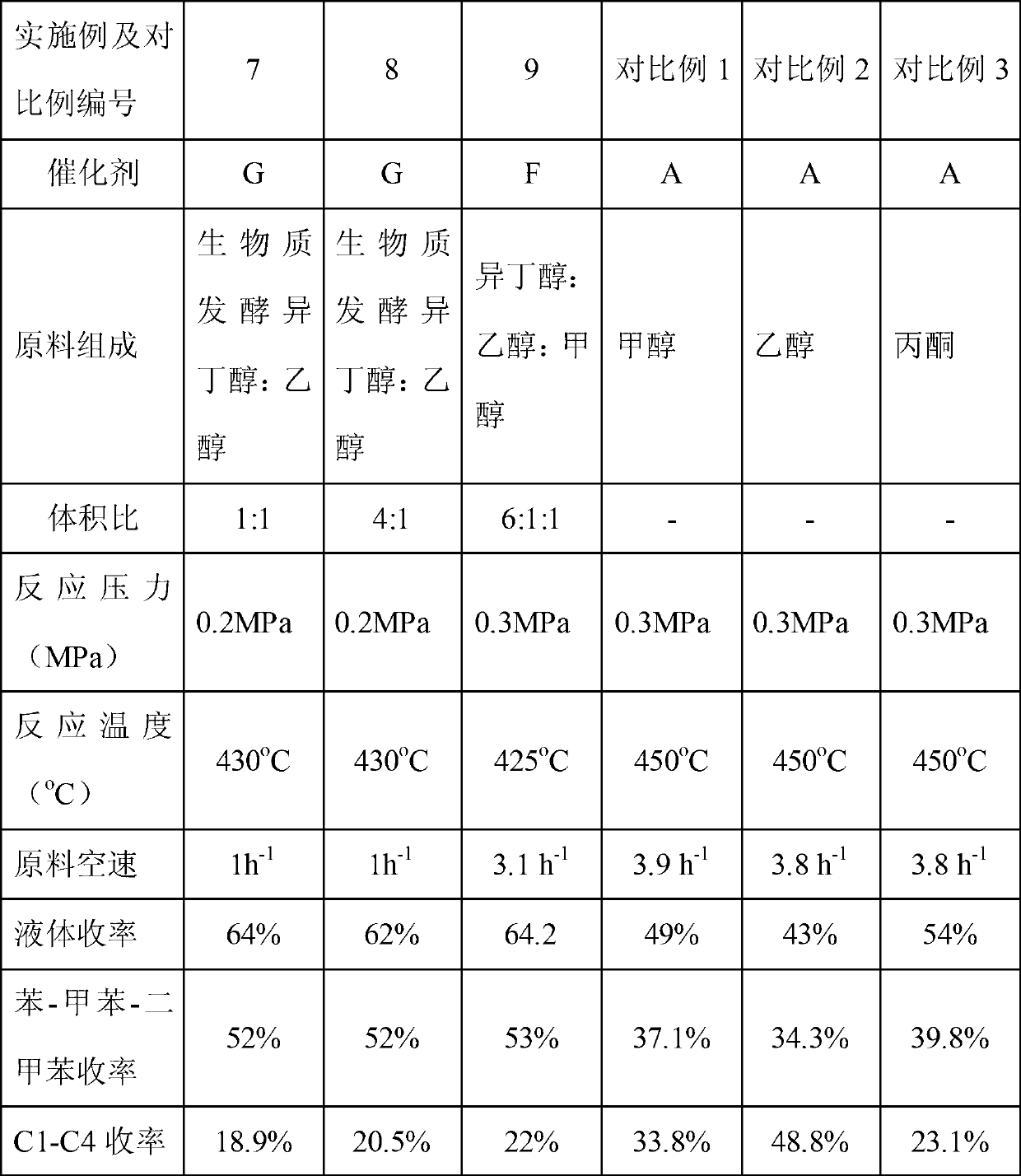

Examples

Embodiment 1

[0021] Take SiO 2 / Al 2 o 3 68 ZSM-5 molecular sieve, fully ground, roasted at 540 ° C for 3 hours, then exchanged with ammonium nitrate solution at 80-90 ° C for 3 times, and then washed with deionized water three times until the Na content is less than 0.05% (mass percentage), after 120 DEG C of drying, 550 DEG C of calcining 3h, make catalyst A.

Embodiment 2

[0023] Take SiO 2 / Al 2 o 3 27 ZSM-5 molecular sieves, fully ground, roasted at 530 ° C for 3 hours, then exchanged with ammonium nitrate solution at 80-90 ° C for 3 times, and then washed with deionized water three times until the Na content is less than 0.05% (mass percentage), after drying at 120°C, roasting at 530°C for 3h. Introduce 2.5% zinc element by impregnating zinc nitrate solution. Weigh a certain amount of zinc nitrate in a beaker, then add deionized water, dissolve and add ammonium nitrate-exchanged molecular sieves, the solid-to-liquid ratio is 1:20, stir magnetically at room temperature for 8 hours, then place in a 60-80°C oven After drying for 24 hours in a muffle furnace at 500° C. for 4 hours, catalyst B was obtained.

Embodiment 3

[0025] Take SiO 2 / Al 2 o 3 80 ZSM-5 molecular sieve, fully ground, roasted at 550°C for 3 hours, then exchanged with ammonium nitrate solution at 80-90°C for 3 times, and then washed with deionized water three times until the Na content is less than 0.05% (mass percentage), after 120 DEG C of drying, 550 DEG C of roasting 5h, make catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com