Preparation process of glycyl-L-tyrosine

A preparation process, tyrosine technology, applied in the field of medicinal chemistry, can solve the problems of long synthetic route, reduce the total yield of aminoacyl-L-tyrosine, etc., reduce the reaction cost, reduce the difficulty of purification, and increase the yield and the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

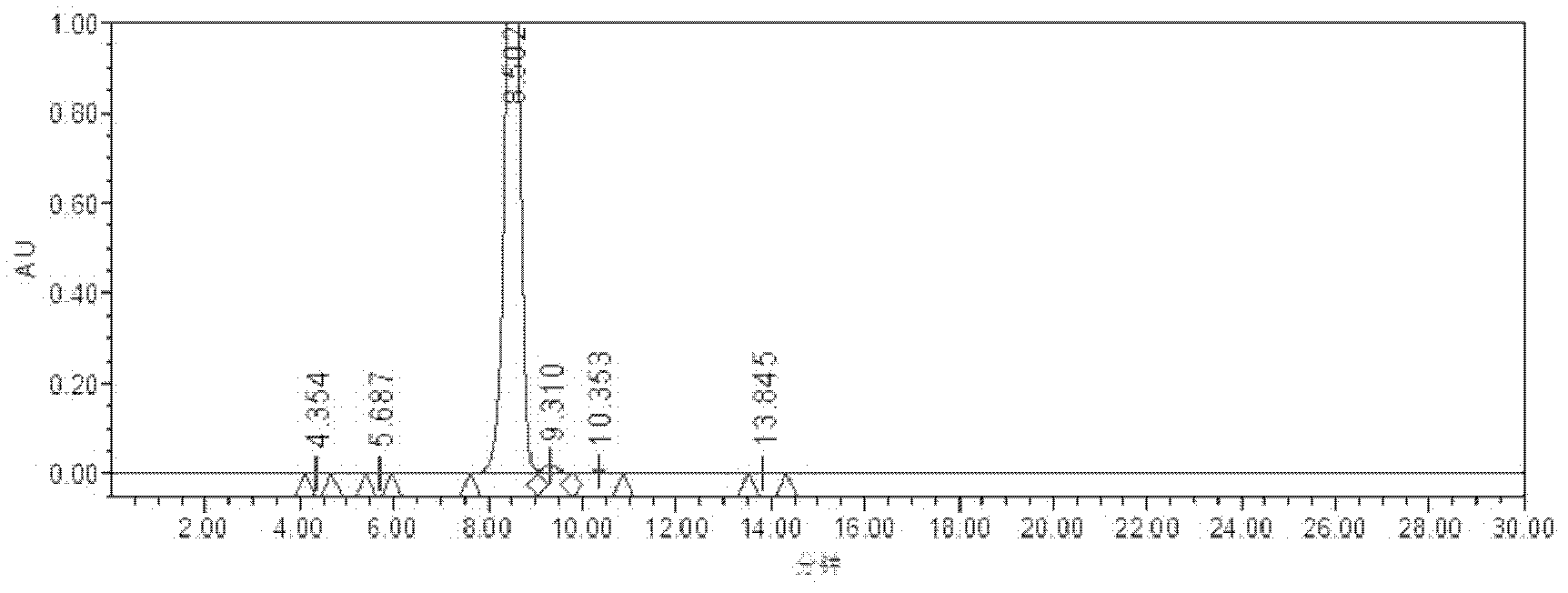

[0039] Add 200ml of concentrated ammonia water to a 250ml single-necked bottle, then add 10g of N-chloroacetyl-L-tyrosine, the solution is heated to 30°C with stirring, and the ammonia is decomposed for about 8 hours. 254 Plate, developer: chloroform-methanol (1:3), reaction product glycyl-L-tyrosine Rf value: about 0.3) monitor the reaction progress, when the L-tyrosine spot in the solution basically disappears, stop reaction. First, remove the ammonia gas at 40°C, -0.09±0.01Mpa, then distill the water to dryness under reduced pressure at 45°C, -0.09±0.01Mpa, add 10ml of purified water until the residue dissolves, and place the solution in Place in the refrigerator overnight for complete crystallization. After filtration, 8.8 g of crude product was obtained, with a yield of 82.3%. The HPLC purity is 98.25%, and the HPLC spectrum is shown in figure 1 , and the HPLC integration results are shown in Table 1.

[0040] The HPLC integral result table of table 1 embodiment 1

...

Embodiment 2

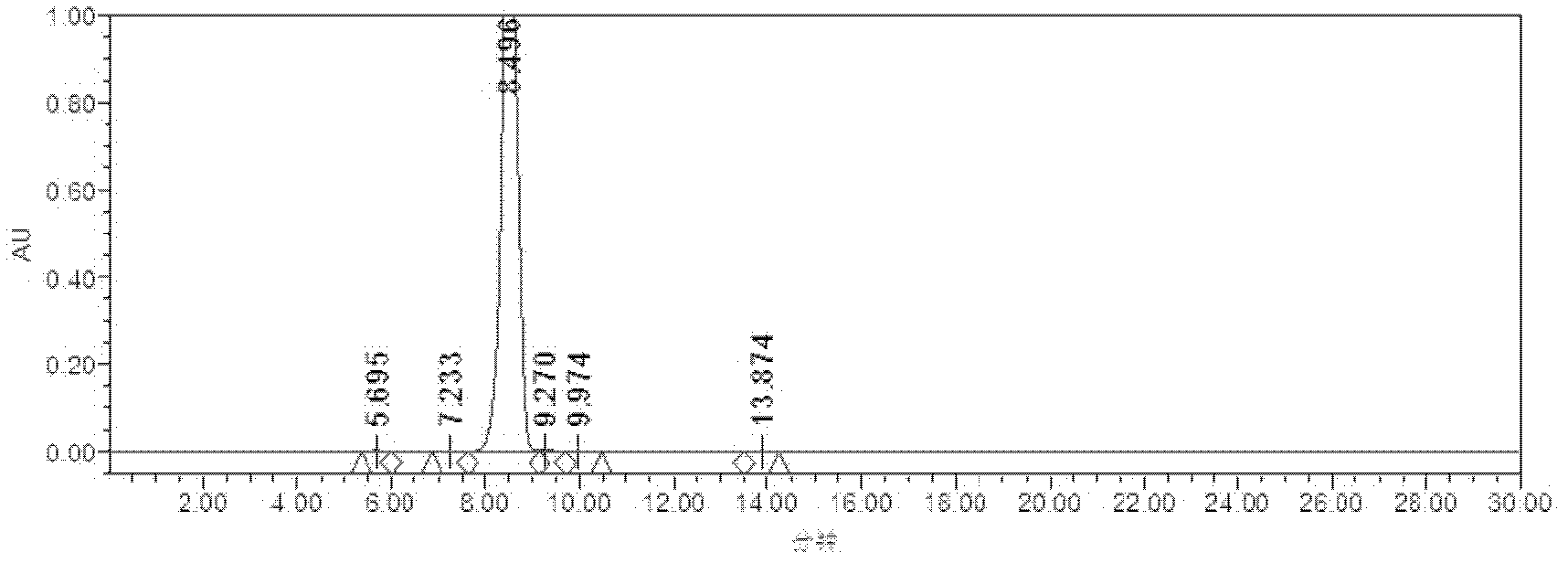

[0043] Add 7.0g of crude glycyl-L-tyrosine and 35ml of purified water into a 250ml single-necked bottle, then slowly heat to 50°C under stirring conditions, at this time the solids are all dissolved, then add 0.14g of activated carbon and stir After 40 minutes, filter while it is hot, continue to add 0.14g of activated carbon to the filtrate, stir at 50°C for 40 minutes, and then filter while it is hot. After the filtrate is slowly cooled to 25±2°C, add 35ml of ethanol dropwise. After the dropwise addition, place it in a Crystallize at -2±2°C for 8 hours to obtain 6.2g of refined glycyl-L-tyrosine with a yield of 88.6% and a HPLC purity of 99.65%. The HPLC spectrum is shown in figure 2 , and the HPLC integration results are shown in Table 2.

[0044] The HPLC integral result table of table 2 embodiment 2

[0045]

Embodiment 3

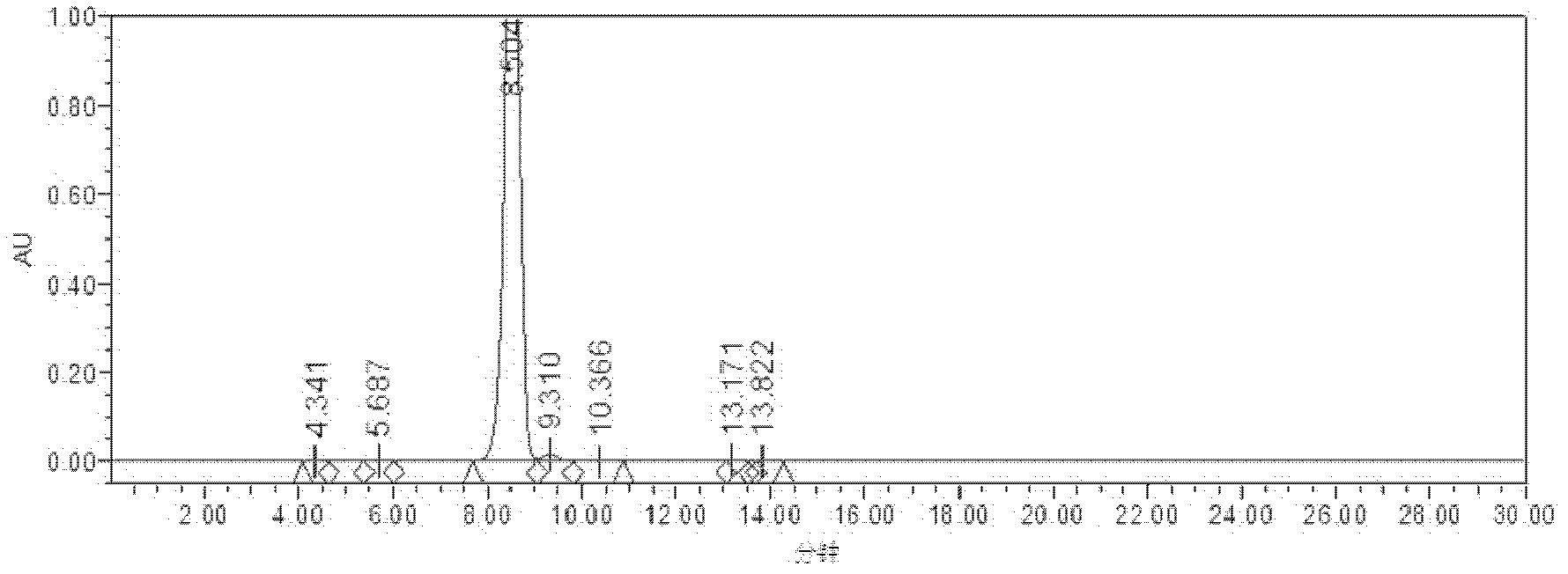

[0047] Add 150ml of concentrated ammonia water to a 250ml single-mouth bottle, then add 10g of N-chloroacetyl-L-tyrosine, the solution is heated to 35°C under stirring, and the ammonia is decomposed for about 10 hours. 254Plate, developer: chloroform-methanol (1:3), reaction product glycyl-L-tyrosine Rf value: about 0.3) monitor the reaction progress, when the L-tyrosine spot in the solution basically disappears, stop reaction. First, remove the ammonia gas at 40°C, -0.09±0.01Mpa, then distill the water to dryness under reduced pressure at 48°C, -0.09±0.01Mpa, add 20ml of purified water until the residue dissolves, and place the solution in Place in the refrigerator overnight for complete crystallization. After filtration, the crude product was 8.6g, and the yield was 80.7%. The HPLC purity is 98.62%, and the HPLC spectrum is shown in image 3 , and the HPLC integration results are shown in Table 3.

[0048] The HPLC integral result table of table 3 embodiment 3

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com