Polythiophene nanometer conductive composite material and preparation method thereof

A technology of nano-composite materials and conductive composite materials, applied in the field of preparation of nano-composite materials, can solve the problems of high cost, achieve low prices, improve comprehensive performance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

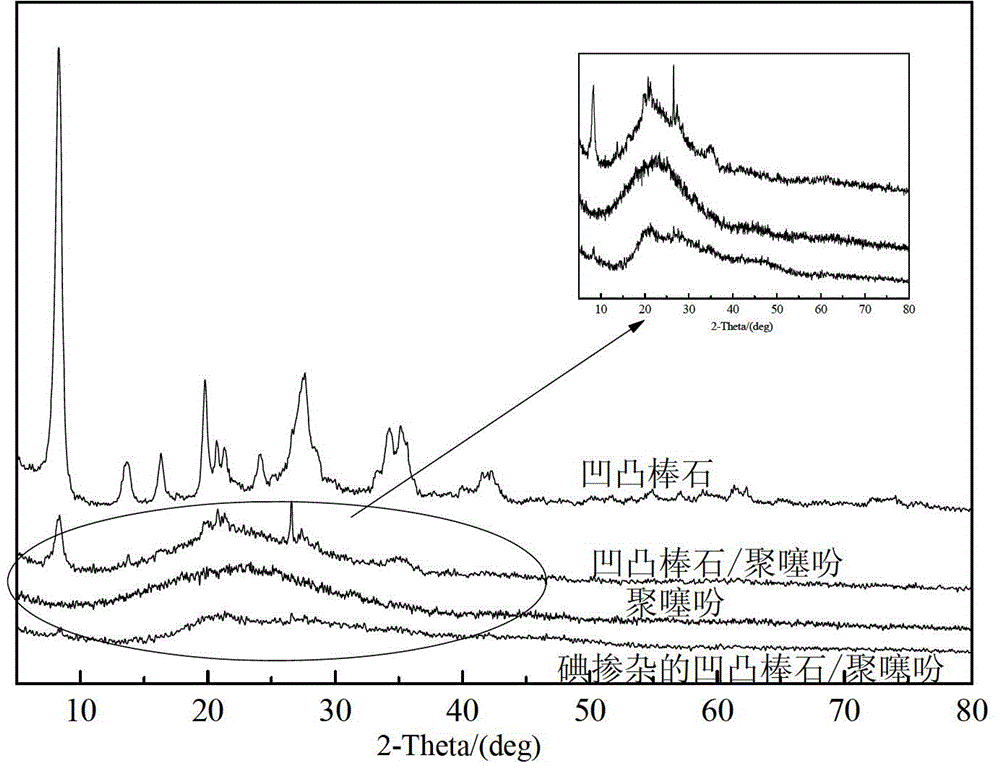

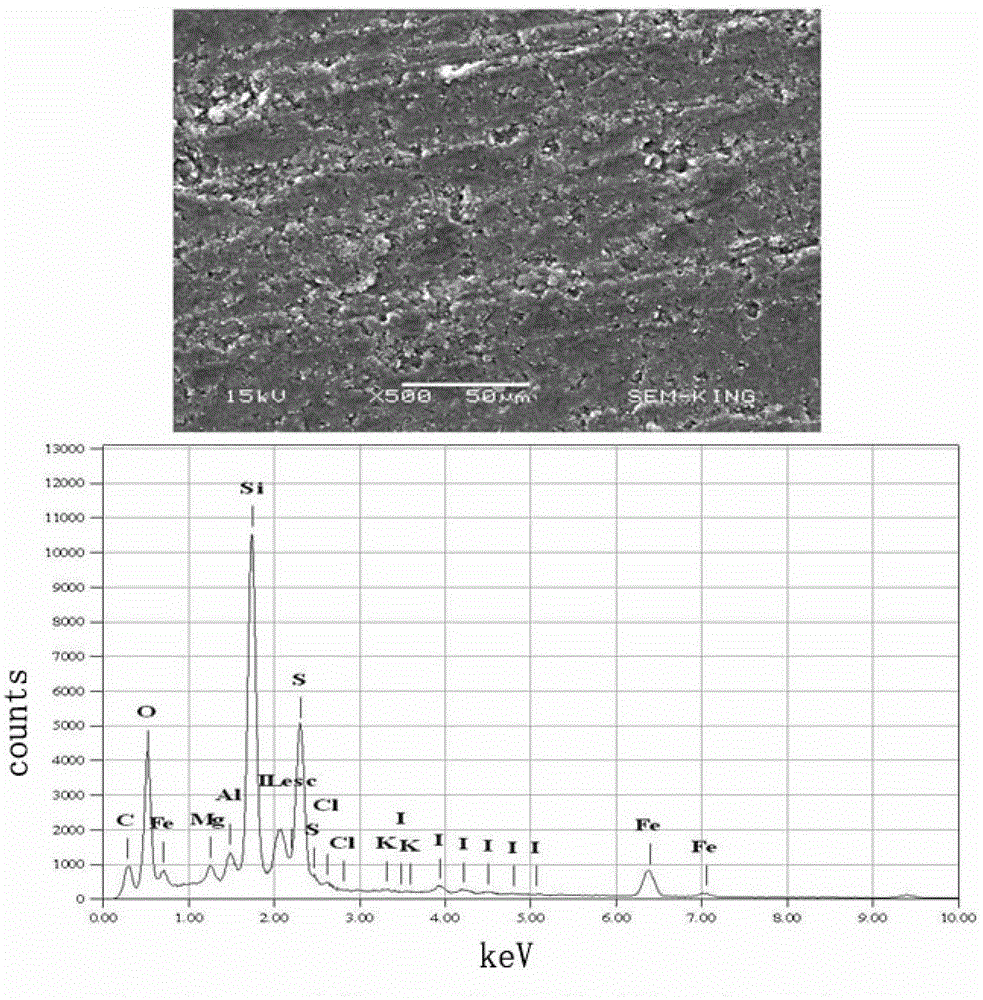

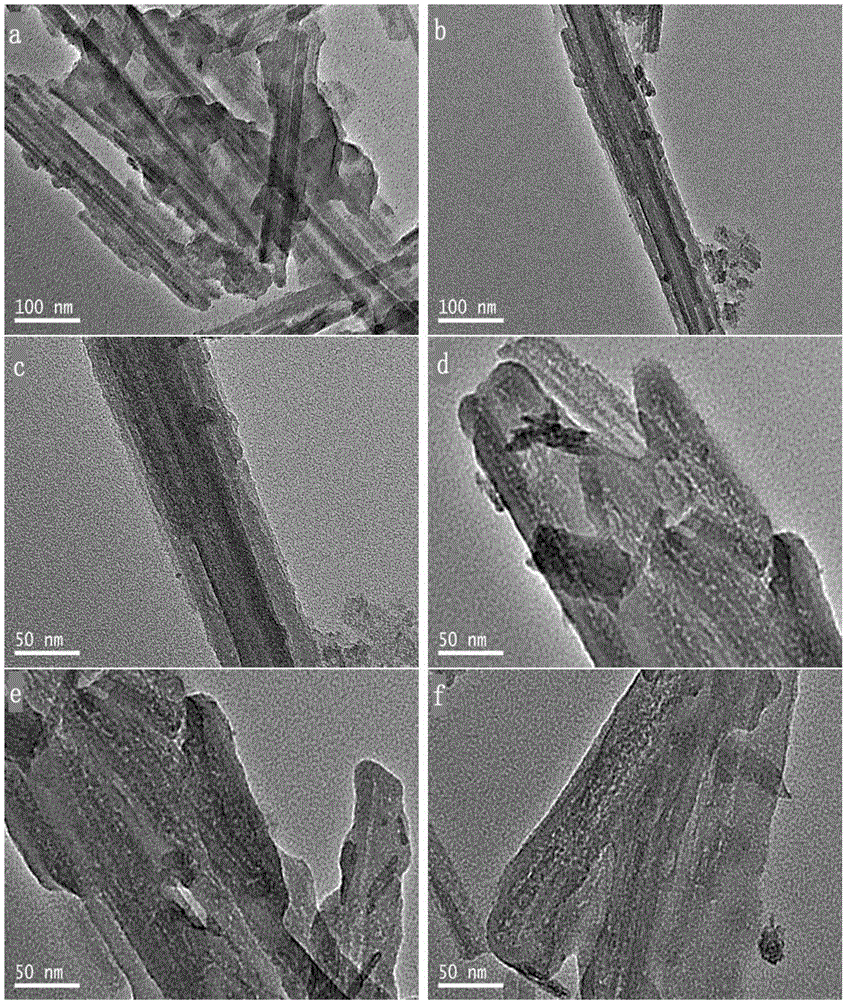

[0025] (1). Add 1.5 grams of thiophene monomer to 10.0 grams of chloroform, disperse 6.0 grams of nano-attapulgite in 20.0 grams of acetone, and then add 5.78 grams of anhydrous ferric chloride to fully dissolve it. While stirring at a temperature of 30°C, drop the acetone dispersion of attapulgite into the chloroform solution of thiophene drop by drop at a rate of 10 ml / min while stirring. After washing and drying, the attapulgite / polythiophene nanocomposite material is obtained;

[0026] (2). Take 5.0 grams of the attapulgite / polythiophene nanocomposite material prepared in step 1 and place it in a closed container, add 1.0 grams of iodine, keep it warm for 10 hours at a temperature of 75°C, and cool to room temperature. A porous rod-shaped silica / polythiophene nanoconductive composite material was prepared.

Embodiment 2

[0028] (1). Add 3.0 grams of thiophene monomer to 40.0 grams of n-hexane, disperse 6.0 grams of nano-attapulgite in 40.0 grams of tetrahydrofuran, and then add 8.14 grams of ammonium persulfate to fully dissolve it. Add the THF dispersion of attapulgite into the n-hexane solution of thiophene drop by drop at a rate of 20 ml / min while stirring under the same conditions, continue to stir after the dropwise addition, keep the temperature for 12 hours, filter, wash, and dry to prepare Obtain attapulgite / polythiophene nanocomposite material;

[0029] (2). Take 5.0 grams of the attapulgite / polythiophene nanocomposite material prepared in step 1 and place it in a closed container, add 4.0 grams of iodine, keep it warm at 110°C for 6 hours, and cool to room temperature. A porous rod-shaped silica / polythiophene nanoconductive composite material was prepared.

Embodiment 3

[0031] (1). Add 1.7 grams of thiophene monomer to 37.5 grams of nitromethane, disperse 5.0 grams of nano-attapulgite in 25.0 grams of propanol, then add 6.92 grams of ammonium persulfate to fully dissolve it, at a temperature of Add the propanol dispersion of attapulgite into the nitromethane solution of thiophene drop by drop at a rate of 12.5 ml / min while stirring at 5°C, continue stirring after the addition, keep the temperature for 10 hours, filter and wash , and dry to obtain the attapulgite / polythiophene nanocomposite material;

[0032] (2). Take 5.0 grams of the attapulgite / polythiophene nanocomposite prepared in step 1 and place it in a closed container, add 2.0 grams of iodine, keep it warm at 90°C for 8 hours, and cool to room temperature. A porous rod-shaped silica / polythiophene nanoconductive composite material was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com