Preparation method of aluminum-doped zinc oxide transparent conductive oxide film

A technology of aluminum-doped zinc oxide and oxide films, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as hindering optical and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

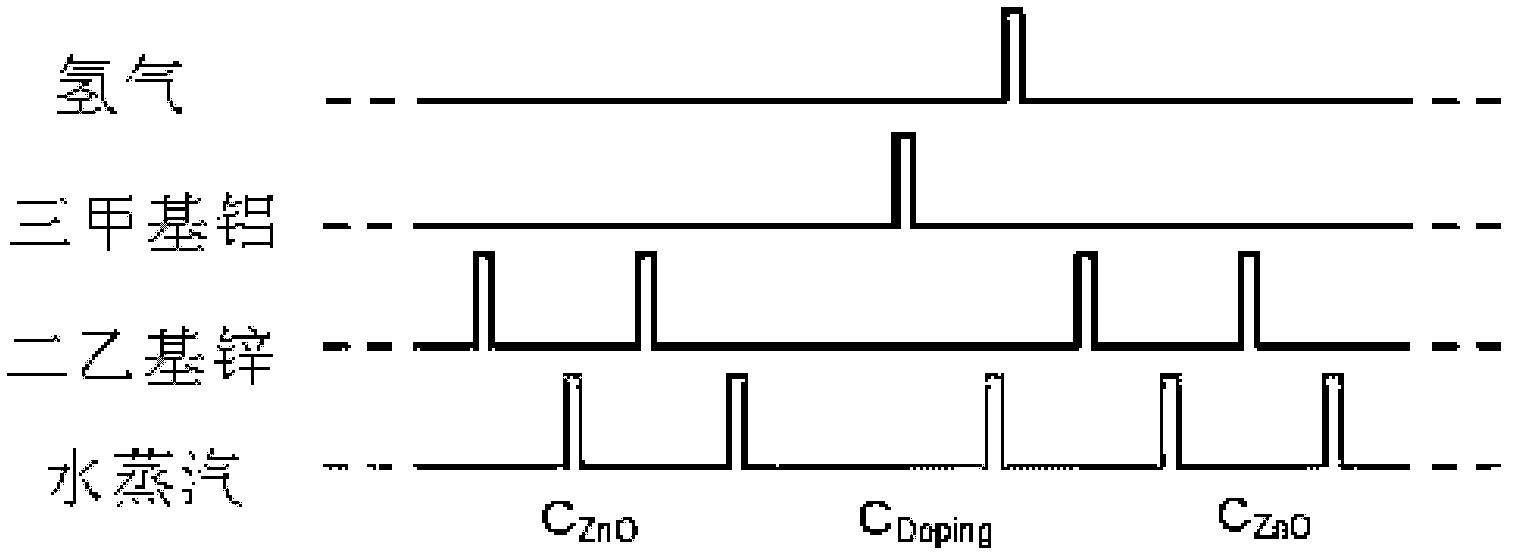

[0019] Use a vacuum pump to evacuate the reaction chamber to a low vacuum below 20hPa and heat it to a specific reaction temperature, and then clean the reaction chamber with high-purity nitrogen with a purity of 5N. Clean the substrate ultrasonically in high-purity deionized water for 10-30 minutes, dry it with a high-purity nitrogen gun, and put it into the reaction chamber until the temperature of the reaction chamber reaches 150°C. The precursor diethylzinc is passed into the reaction chamber with a pulse time of 0.1s, and the pulse time for cleaning diethylzinc is 3s; then a 0.2s water vapor pulse is introduced, and the excess water vapor is cleaned with a 4s pulse time. So far, one cycle of deposition of the zinc oxide film is completed. After 30 such cycles, the precursor trimethylaluminum with a pulse time of 0.2s is introduced to make it chemically saturated and adsorbed on the surface of the zinc oxide layer, and then the excess aluminum precursor is cleaned with a 4...

Embodiment 2

[0021] Use a vacuum pump to evacuate the reaction chamber to a low vacuum below 20hPa and heat it to a specific reaction temperature, and then clean the reaction chamber with high-purity nitrogen with a purity of 5N. Clean the substrate ultrasonically in high-purity deionized water for 10-30 minutes, dry it with a high-purity nitrogen gun, and put it into the reaction chamber until the temperature of the reaction chamber reaches 150°C. The precursor diethylzinc is passed into the reaction chamber with a pulse time of 0.1s, and the pulse time for cleaning diethylzinc is 3s; then a 0.2s water vapor pulse is introduced, and the excess water vapor is cleaned with a 4s pulse time. So far, one cycle of deposition of the zinc oxide film is completed. After 30 such cycles, the precursor trimethylaluminum with a pulse time of 0.2s is introduced to make it chemically saturated and adsorbed on the surface of the zinc oxide layer, and then the excess aluminum precursor is cleaned with a 4...

Embodiment 3

[0023] Use a vacuum pump to evacuate the reaction chamber to a low vacuum below 20hPa and heat it to a specific reaction temperature, and then clean the reaction chamber with high-purity nitrogen with a purity of 5N. Clean the substrate ultrasonically in high-purity deionized water for 10-30 minutes, dry it with a high-purity nitrogen gun, and put it into the reaction chamber until the temperature of the reaction chamber reaches 150°C. The precursor diethylzinc is passed into the reaction chamber with a pulse time of 0.1s, and the pulse time for cleaning diethylzinc is 3s; then a 0.2s water vapor pulse is introduced, and the excess water vapor is cleaned with a 4s pulse time. So far, one cycle of deposition of the zinc oxide film is completed. After 30 such cycles, the precursor trimethylaluminum with a pulse time of 0.2s is introduced to make it chemically saturated and adsorbed on the surface of the zinc oxide layer, and then the excess aluminum precursor is cleaned with a 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com