Preparation method of multilayer ceramic composite membrane for improving safety of secondary battery

A secondary battery and ceramic composite technology, applied in the field of secondary batteries, can solve the problems of reducing ionic conductivity and affecting ionic conductivity, and achieve the effects of avoiding short circuits, high ionic conductivity, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

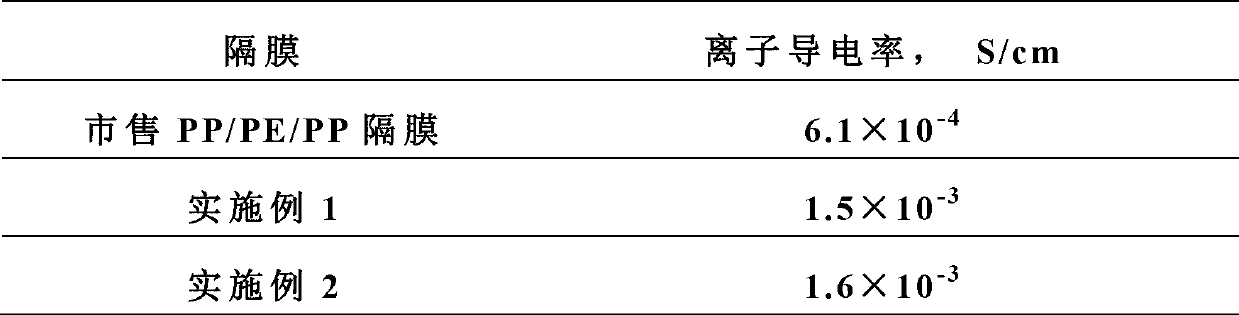

[0044] Embodiment 1 (PP / Al 2 o 3 ) / PE / (PP / Al 2 o 3 ) three-layer composite diaphragm

[0045] (1) Prepare the first viscous mixture. Add 35wt% HDPE (weight average molecular weight = 1×10 6 , Molecular weight distribution index = 3.2), 0.5% of the weight of HDPE antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate was put into the extruder with stirring device Mix in the machine hopper, and at the same time add 65wt% paraffin oil through the side feeding port with a metering pump, and melt and knead at 200 °C through a co-rotating twin-screw extruder.

[0046] (2) Prepare the second viscous mixture. Add 28wt% PP (weight average molecular weight = 6×10 5 , molecular weight distribution index = 3.6), accounting for 0.5% by weight of PP antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate and 7wt% Al 2 o 3 (Particle size distribution 50-100nm, surface treated by 1wt% aluminate coupling agent) put into another extruder hopper with stirrin...

Embodiment 2

[0051] Embodiment 2 (PP / Al 2 o 3 ) / PP / (PP / Al 2 o 3 ) three-layer composite diaphragm

[0052] (1) Prepare the first viscous mixture. Mix 35wt% PP (weight average molecular weight = 1×10 5 , molecular weight distribution = 4.1), 0.5% of PP weight antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate was put into the extruder with stirring device Mix in the hopper, and at the same time add 65wt% paraffin oil through the side feeding port with a metering pump, and melt and knead at 210°C through a co-rotating twin-screw extruder.

[0053] (2) Prepare the second viscous mixture. Add 28wt% PP (weight average molecular weight = 6×10 5 , molecular weight distribution = 3.6), accounting for 0.5% by weight of PP antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate and 7wt% Al 2 o 3 (Particle size distribution 50-100nm, surface treated by 1wt% aluminate coupling agent) put into another extruder hopper with stirring device and mix evenly, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com