Device and method for adjusting ring cavity of excimer laser device

A technology of excimer lasers and adjustment devices, which is applied in the field of excimer lasers, can solve the problems of not being able to find the position of the beam, the small cross-sectional area of the discharge area, and the loss of reference light, so as to achieve simple operation, reduce loss, and overcome limitations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

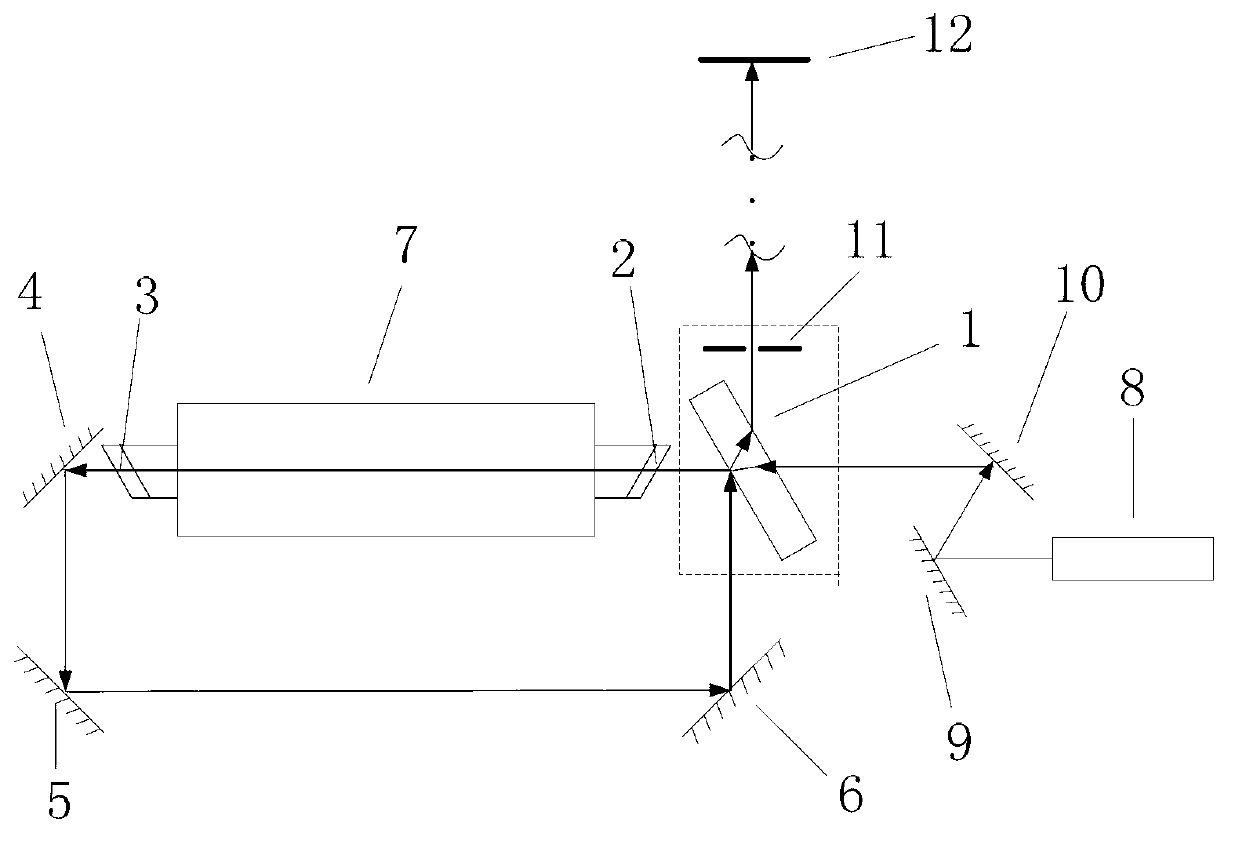

[0043] The reference light source used is a 532nm single longitudinal mode all-solid-state laser, the excimer laser used is an ArF excimer laser, the mirrors 9 and 10 used are gold-plated mirrors, and the mirrors 4, 5 and 6 used are plated for 193nm laser at a 45-degree incident angle. Anti-reflective film, the coupling mirror 1 used is coated with an anti-reflective coating on one side close to the sealing window, and the incident reflectance at 45 degrees is 50%, and the other side is coated with an anti-reflection film, and the incident transmittance at 45 degrees is greater than 99%. The diameter of the reference light spot is 2-4mm, the aperture diameter of the pinhole diaphragm is 3-4mm, and the far point is 8m away from the pinhole diaphragm.

[0044] Because the reference light and excimer laser are harmful to human eyes, the observer should wear laser protective glasses.

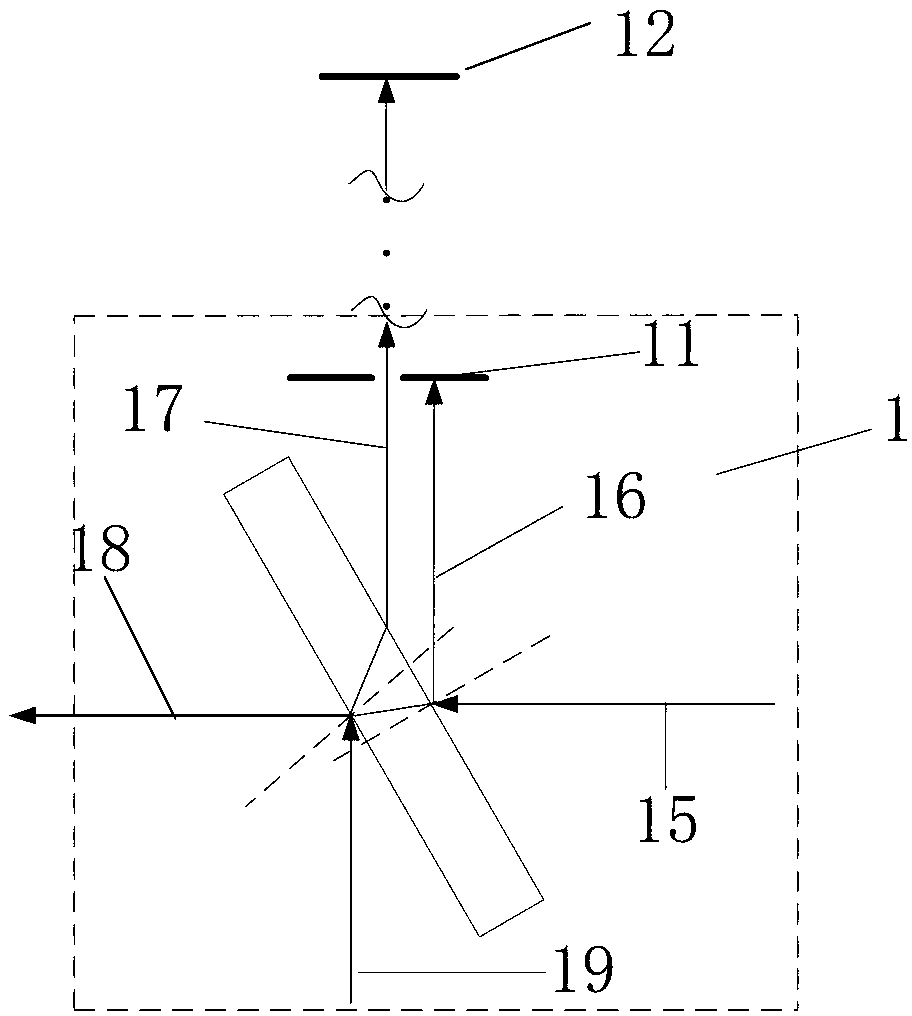

[0045] Figure 4 It is a schematic diagram of the annular cavity after adding a reflector. Bec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com