A chip-integrated silicon oxide microsphere laser

A technology of silicon oxide microspheres and lasers, which is applied in the field of micro-optical devices, can solve the problems of low threshold and inability to realize chip integration, and achieve the effect of low threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation process of silicon oxide microsphere laser of the present invention is as follows:

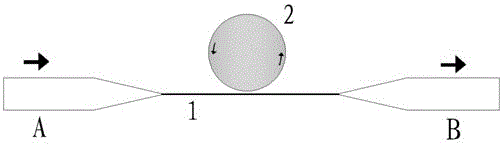

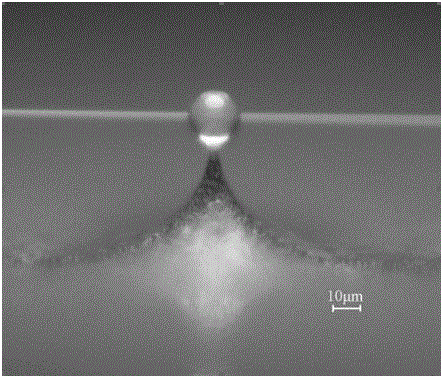

[0024] (1) First prepare a silicon oxide film by sol-gel method, in which rare earth impurities are mixed, and the thickness of the film is 1 μm to 2 μm; (2) After photolithography, wet etching and dry etching, silicon oxide microdisks are obtained; (3) Use a carbon dioxide laser to heat and reflow the silica microdisk to melt the silica microdisk into microspheres; (4) Draw a single-mode fiber with a diameter of 125um into a microfiber with a diameter of about 1μm by high temperature stretching method, and Control the loss below 5%; (4) place the microfiber close to the microsphere resonator to ensure the best coupling between the two; (5) input the pump light from port A to the microsphere resonator 2, and Gradually increase the pump power. When the pump power exceeds the threshold, laser light will be output from port B. Continue to increase the pump light to get diff...

Embodiment 1

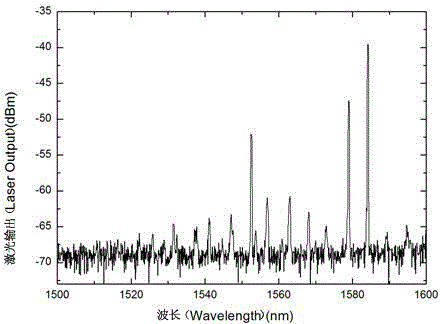

[0026] Silicon oxide film was prepared by sol-gel method, and doped impurity concentration was 2×10 19 cm -3 Erbium ions with a film thickness of 1.3 μm. After photolithography, wet etching and dry etching, a silicon oxide microdisk is obtained. The silicon oxide microspheres are obtained by heating and reflowing the silicon oxide microdisks by using a carbon dioxide laser. On the other hand, a micro-fiber with a diameter of 1 μm to 2 μm is prepared by using a high-temperature stretching method for an ordinary single-mode fiber. Then put the silicon oxide microspheres on the three-dimensional piezoelectric console, precisely control their position, and slowly bring the two closer together. Bring the two together, find the best coupling point, and input continuous pump light with a wavelength of about 1480nm, and continuously increase the pump power to excite rare earth ions to generate fluorescence. When the gain of rare earth ions is greater than the loss in the cavity, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com