Aqueous solution capable of absorbing and collecting carbon dioxide in exhaust gas with high efficiency

A carbon dioxide and aqueous solution technology, applied in the direction of absorption, inorganic chemistry, gas treatment, etc., can solve the problems of reduced heat transfer performance, reduced absorption rate, increased viscosity, etc., to achieve reduced energy consumption, reduced circulation flow, and reduced operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

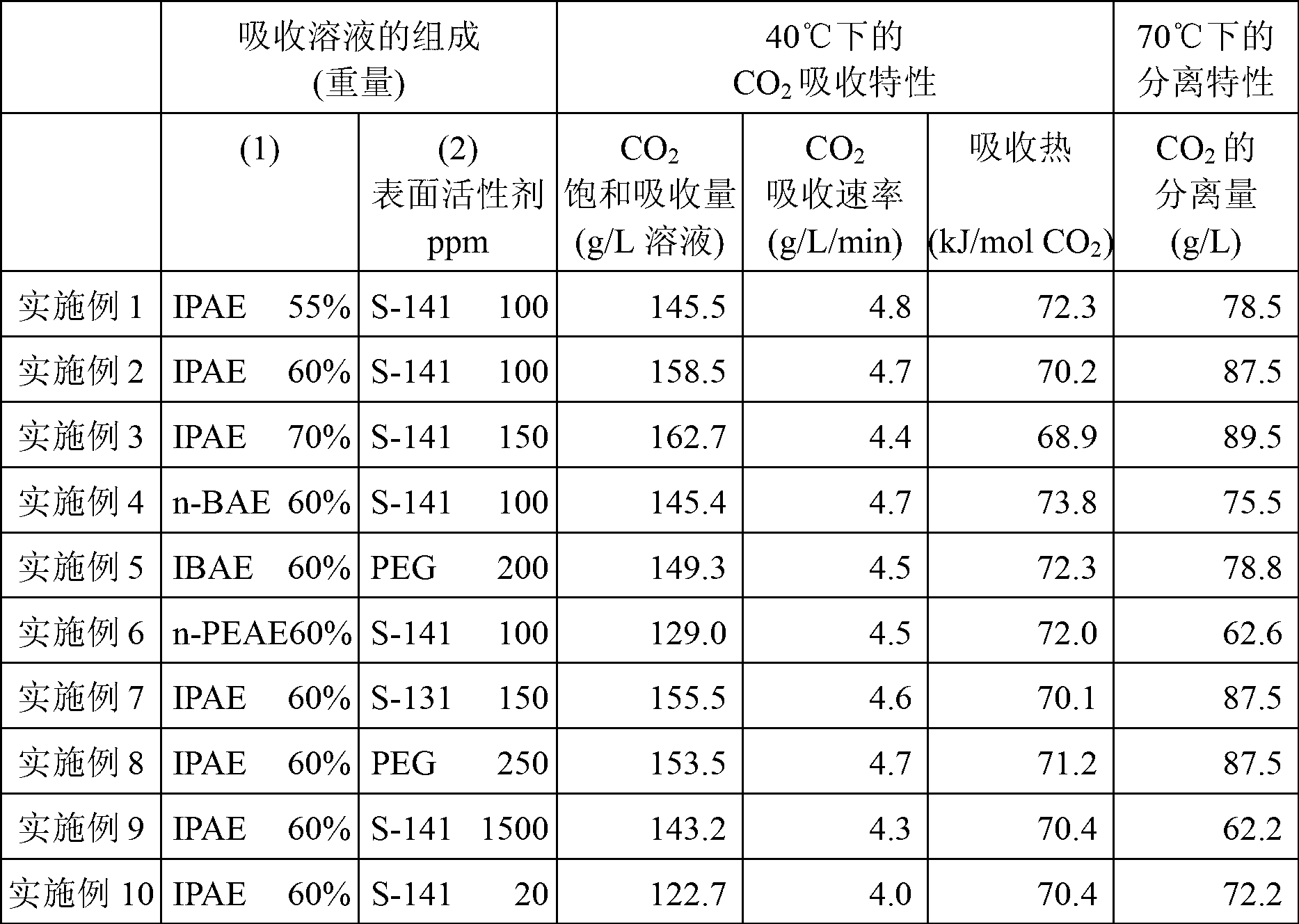

Embodiment 1

[0079] The gas-washed glass bottle was immersed in a constant temperature water bath whose liquid temperature was set at 40°C. The bottle contained 50 mL of an aqueous solution (absorption solution) containing 55% by weight of IPAE (reagent, manufactured by Tokyo Chemical Industry Co., Ltd.) and 100 ppm by weight of Surflon S-141 (produced by AGC Seimi Chemical Co., Ltd.), which is a nonionic perfluorinated compound. As a result of measurement using Drop Master 300 manufactured by Kyowa Interface Science Co., Ltd., the surface tension of the absorption solution at 25° C. before absorption was performed was 25 mN / m. A gas mixture of 20% by volume of carbon dioxide and 80% by volume of nitrogen was dispersed in the solution as bubbles at a rate of 0.7 L / min through a glass filter with a pore size of 100 μm and a diameter of 13 mm at atmospheric pressure to perform absorption for 60 minutes .

[0080] The CO in the gas was measured continuously at the inlet and outlet of the ab...

Embodiment 2 and 3

[0084] CO 2 Saturation absorption, CO 2 Absorption rate, CO 2 heat of absorption and CO 2 The amount of separation was measured as described in Example 1, except that an aqueous solution containing 60 or 70 wt. % of IPAE and 100 or 150 ppm wt. concentration of Surflon S-141 as surfactant was used instead of 55 wt. An aqueous solution of IPAE and 100 ppm of S-141. The surface tensions of these surfactant-containing absorption solutions were 24 mN / m and 23 mN / m, respectively. CO at 40°C 2 The saturated absorption capacity is 158.5g / L and 162.7g / L respectively, the absorption rate is 4.7g / L / min and 4.4g / L / min respectively, CO at 70°C 2 The separation amounts of the samples were 87.5g / L and 89.5g / L respectively.

Embodiment 4 to 6

[0086] CO 2 Saturation absorption, CO 2 Absorption rate, CO 2 heat of absorption and CO 2 The amount of isolation was measured as described in Example 2, except that the type of the alkyl group in the alkylaminoalcohol was changed from isopropyl to n-butyl (n-BAE), isobutyl (IBAE) or n-pentyl (n-PEAE). In Example 5 using IBAE, Triton X, a nonionic polyoxyethylene alkyl ether, was used as a surfactant at a concentration of 200 ppm by weight. The surface tensions of these absorption solutions were 22, 25 and 23 mN / m, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com