Positive electrode for lithium secondary batteries and lithium secondary battery using same

A technology of lithium secondary battery and positive electrode, which is applied in the field of positive electrode for lithium secondary battery and lithium secondary battery using the same, can solve the problems of low electronic conductivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0142] [Positive Electrode for Lithium Secondary Battery of First Embodiment]

[0143] Next, the positive electrode for a lithium secondary battery according to the first embodiment of the present invention will be described.

[0144] The positive electrode for a lithium secondary battery of the present invention is formed by forming a positive electrode active material layer containing the specific carbon black as a conductive material described in the present invention, an active material, and a binding material (binder) on a collector. into.

[0145]The positive electrode active material layer is usually produced by mixing the conductive material, the positive electrode active material, the binder material, and the thickener used if necessary, and forming a sheet, and pressing the sheet to the positive electrode. A current collector; or these materials are dissolved or dispersed in a liquid medium to form a slurry, which is applied to the positive electrode current collect...

no. 2 approach

[0412] [Positive Electrode for Lithium Secondary Battery of Second Embodiment]

[0413] Next, a positive electrode for a lithium secondary battery according to a second embodiment of the present invention will be described.

[0414] The positive electrode for a lithium secondary battery according to the second embodiment of the present invention is the same as the first embodiment except that the following binders are used as the binder.

[0415] [adhesive material]

[0416] The binding material used in the manufacture of the positive electrode active material layer is not particularly limited. In the case of the coating method, as long as it is a material that is dissolved or dispersed in the liquid medium used in the manufacture of the positive electrode, as a specific example, Examples include polyethylene, polypropylene, polyethylene terephthalate, polymethyl methacrylate, aromatic polyamide, cellulose, nitrocellulose and other resin-based polymers, SBR (styrene-butadiene...

Embodiment

[0486] The following examples and comparative examples are given to describe the present invention more specifically, but the present invention is not limited to the following examples unless the gist thereof is exceeded.

[0487] [active substance]

[0488] [Measurement method of physical properties]

[0489] The physical properties and the like of the lithium-transition metal-based compound powders produced in Examples and Comparative Examples described later were measured as follows.

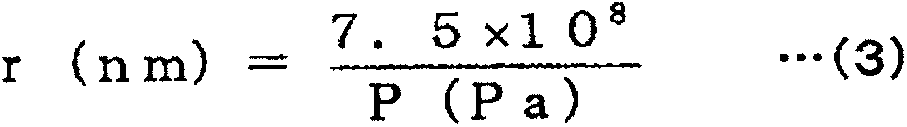

[0490]

[0491] Obtained by ICP-AES analysis.

[0492]

[0493] Obtained by ICP-AES analysis.

[0494]

[0495] The X-ray photoelectron spectrometer "ESCA-5700" manufactured by Physical Electronics was used under the following conditions.

[0496] X-ray source: monochromatic AlKα

[0497] Analysis area: 0.8mm diameter

[0498] Outgoing angle: 65°

[0499] Quantitative method: Correction of Bls, Mn2p with sensitivity coefficient 1 / 2 、Co2p 3 / 2 , Ni2p 3 / 2 , The area of each peak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com