Device and method for removing pesticide residue from plant by supercritical carbon dioxide

A carbon dioxide and pesticide residue technology, applied in the production/processing of edible oil/fat, food science, edible oil/fat, etc., can solve the problems of difficult removal, achieve high removal efficiency, easy and automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

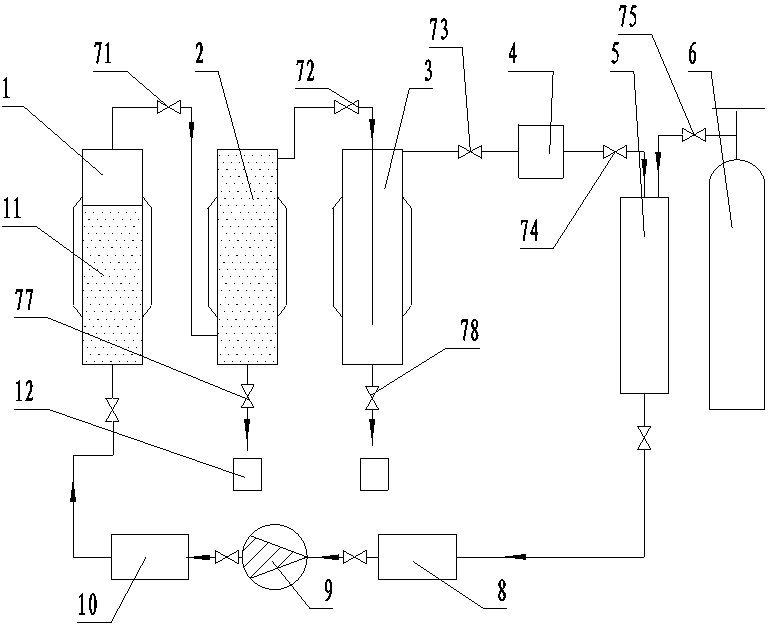

Image

Examples

Embodiment 1

[0021] Example 1: In supercritical CO 2 In the extraction kettle 1, there is a 3 / 4-4 / 5 height stainless steel packing 10-1 Pall ring (conjugated ring, step ring or double saddle ring can also be used), take 5.00kg corn oil, which contains organic Chlorpyrifos phosphorus 0.198 ppm, put into the extraction kettle, the liquid level should be lower than or equal to the upper surface of packing 11, reserve 1 / 4-1 / 5 space in the upper part of the kettle, CO 2 From the carbon dioxide cylinder 6 through the control valve 75 into the carbon dioxide storage tank 5, after passing through the cooling heat exchanger 8, high-pressure pump 9, and heating heat exchanger 10, it becomes supercritical CO 2 , inject the extraction kettle 1 from the bottom of the extraction kettle 1, keep the pressure inside the extraction kettle 1 at 20MPa, 35°C, supercritical CO 2 After fully mixing with corn oil for 30 minutes, start supercritical extraction. The flow rate of carbon dioxide is 100L / hr, and extr...

Embodiment 2

[0022] Example 2: In supercritical CO 2 In the extraction kettle 1, there is a 3 / 4 height stainless steel filler 11 as a conjugate ring, take 5.00kg of rapeseed oil, which contains organic phosphorus triazophos 0.468ppm and dichlorvos (DDV) 1.0ppm, and add it to the extraction kettle, Inject supercritical carbon dioxide and mix thoroughly at 25MPa and 40°C for 20 minutes, then start supercritical extraction with a flow rate of carbon dioxide of 110L / hr. The pressure of the fractionation column is 10MPa. In the fractionation column, the temperature of the upper section is 52°C, the temperature of the lower section is 38°C, the separation tank is 6MPa, the temperature is 35°C, extraction and fractionation are carried out for 6.5hrs, and after removal of pesticide residues, rapeseed oil without pesticide residues is obtained 4.30 kg, the residues of organophosphorus triazophos and dichlorvos DDV detected by gas chromatography with flame photometric detector (GC-FPD) are lower th...

Embodiment 3

[0023] Example 3: In supercritical CO 2 In the extraction kettle 1, 4 / 5 height stainless steel packing 11 double saddle rings are housed, get 5.0kg peanut oil, contain endosulfan 0.075ppm, fenpropathrin 0.131ppm, cypermethrin 0.125ppm, fenvalerate 0.101ppm and Bifenthrin 0.130ppm A total of five pyrethroid pesticide residues were added to the extraction kettle, injected with supercritical carbon dioxide, mixed thoroughly at 30MPa and 40°C for 25min, and then began to perform supercritical extraction. The flow rate of carbon dioxide was 120L / hr. The pressure of the fractionation column is 12MPa, the temperature of the upper section is 55°C, the temperature of the lower section is 40°C, the separation tank is 6MPa, the temperature is 35°C, extraction and fractionation is carried out for 6 hours, and after removal of pesticide residues, 4.02kg of peanut oil without pesticide residues is obtained. Gas chromatography (GC-ECD) detects that the contents of the above five pesticide re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com