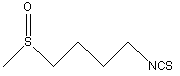

Preparation method of pH sensitiveness raphanin chitosan microsphere

A technology of chitosan microspheres and sulforaphane, which is applied in the direction of medical preparations, pharmaceutical formulas, anti-tumor drugs, etc. of non-active ingredients, to achieve the effects of simple and gentle experiments, improved bioavailability, and easy release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Dissolve chitosan powder with a degree of deacetylation of 91.2% in a 3% acetic acid solution to make the final concentration of chitosan in the solution reach 3mg / ml, adjust the pH value of the above solution to 5.0, and then in turn Filter through 85μm filter paper and 0.45μm filter membrane;

[0026] 2) Take an aqueous solution of sulforaphane at a concentration of 25mg / ml and add it to the chitosan acetic acid solution prepared in step 1) so that the final mass ratio of sulforaphane to chitosan in the solution is 1:2;

[0027] 3) Use a 7 gauge needle to drop 0.6 mg / ml of sodium tripolyphosphate solution into the mixed solution obtained in step 2) at 25°C and 300 rpm at a speed of 3 drops / sec to make the tripolyphosphate in the solution The final mass ratio of sodium to chitosan is 1:5, and stirring is continued for 1.2 hours to obtain sulforaphane-chitosan microspheres.

[0028] The sulforaphane chitosan microspheres have a particle size of 498.2nm, a Poly.Index of 0....

Embodiment 2

[0031] 1) Dissolve chitosan powder with a degree of deacetylation of 92% in a 1% acetic acid solution to make the final concentration of chitosan in the solution reach 0.5 mg / ml, adjust the pH of the above solution to 4.8, and then Filter by 80μm filter paper and 0.15μm filter membrane in turn;

[0032] 2) Take the 10mg / ml sulforaphane aqueous solution and add it to the chitosan acetic acid solution prepared in step 1), so that the final mass ratio of sulforaphane to chitosan in the solution is 1:1;

[0033] 3) At 10℃, 400rpm speed, use a 7 gauge needle to drop 0.4mg / ml sodium tripolyphosphate solution into the mixed solution obtained in step 2), the dropping rate is 5 drops / sec, so that the tripolyphosphate in the solution The final mass ratio of sodium to chitosan is 1:4, and stirring is continued for 1.5 hours to obtain sulforaphane-chitosan microspheres.

[0034] The sulforaphane chitosan microspheres have a particle size of 474.1nm, a Poly.Index of 0.613, a Zeta potential of 29...

Embodiment 3

[0037] 1) Dissolve chitosan powder with a degree of deacetylation of 95% in an acetic acid solution with a concentration of 5% to make the final concentration of chitosan in the solution reach 5.5 mg / ml, adjust the pH of the above solution to 4.8, and then Filter through 100μm filter paper and 0.55μm filter membrane in turn;

[0038] 2) Take an aqueous solution of sulforaphane with a concentration of 40mg / ml and add it to the chitosan acetic acid solution prepared in step 1) so that the final mass ratio of sulforaphane to chitosan in the solution is 1:4;

[0039] 3) Use a 7 gauge needle to drop 0.8 mg / ml sodium tripolyphosphate solution into the mixed solution obtained in step 2) at 30°C and 100 rpm rotation speed. The dropping rate is 1 drop / sec to make the tripolyphosphate in the solution The final mass ratio of sodium to chitosan is 1:6, and stirring is continued for 1 hour to obtain sulforaphane-chitosan microspheres.

[0040] The sulforaphane chitosan microspheres have a parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com