Organic solvent recovery apparatus for increasing recovery quality, method and uses thereof

A technology for organic solvents and recovery devices, applied in organic chemistry, separation methods, chemical instruments and methods, etc., can solve problems such as cost, recovery solvent purification difficulties, reduction of recovery solvent purity, PH value and reuse value, etc., to achieve improvement The effect of recycled quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

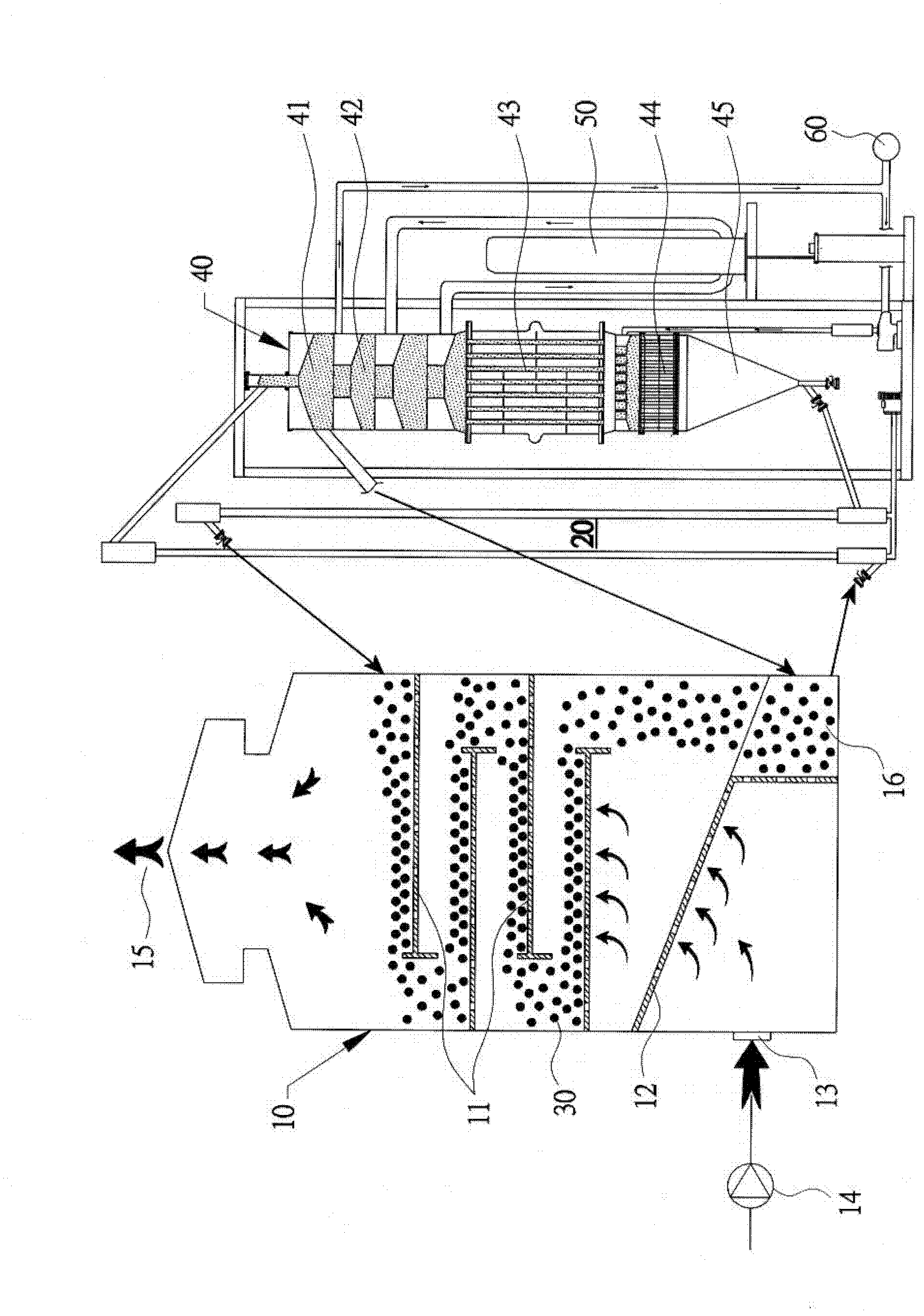

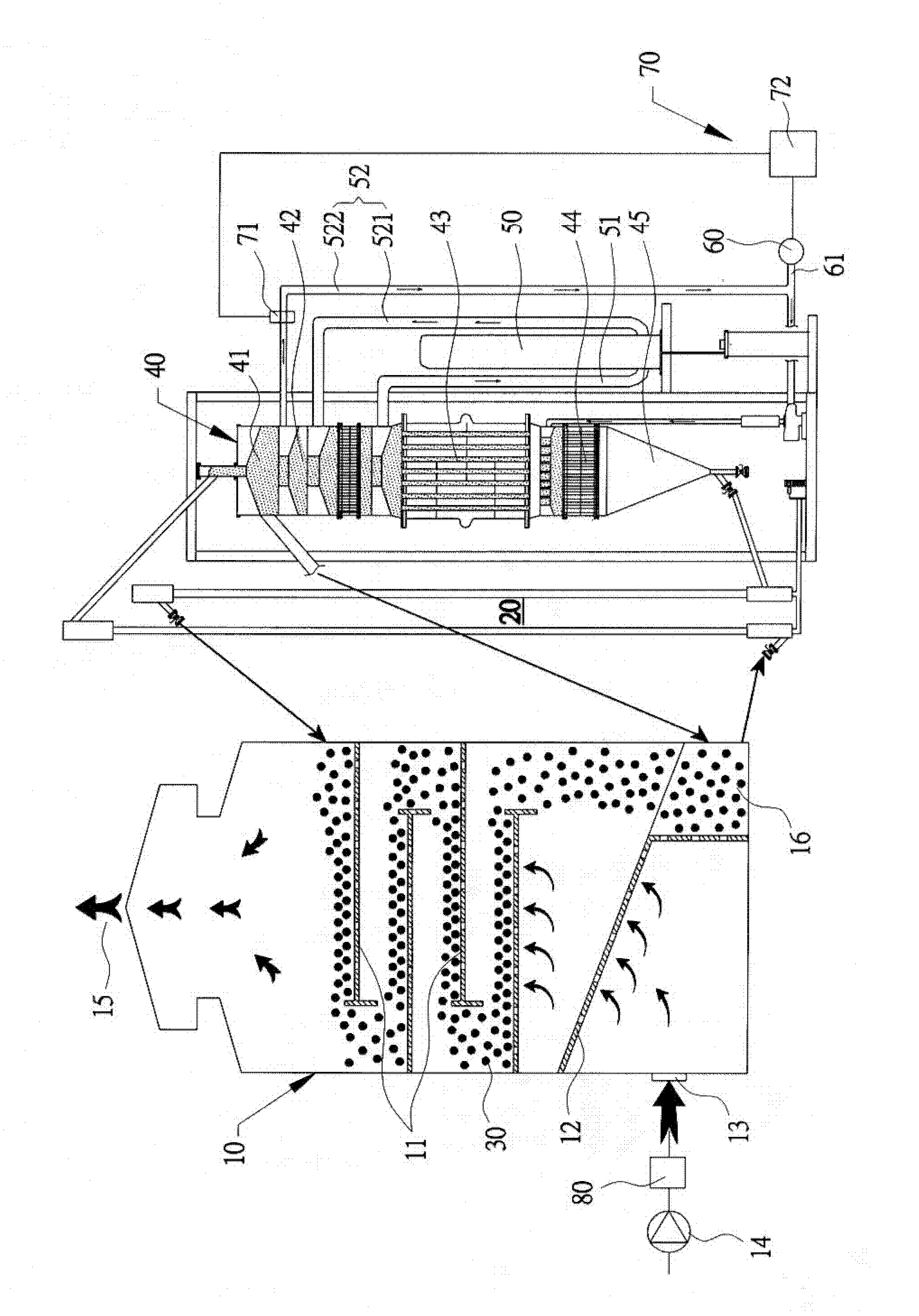

[0046] First, see figure 2 Shown, recovery device of the present invention comprises:

[0047]An adsorption tower 10, the bottom is provided with an organic waste gas inlet 13, and this organic waste gas inlet 13 can be further provided with a humidity control unit 80 (in order to control the relative humidity of the waste gas entering the adsorption tower 10 below 60% RH, more preferably 45% Below RH), the top is provided with a purified gas outlet 15, and the inside is divided into several layers by a porous plate 11 and a storage tank 16 is formed at the bottom, which is sent to the bottom of the adsorption tower 10 from the organic waste gas inlet 13 with the waste gas blower 14, while the organic After the exhaust gas is dispersed by the airflow dispersion plate 12, the adsorbent material 30 falling from the top forms a floating layer above each of the porous plates 11, and falls to the storage tank 16 along the opening side of each of the porous plates 11 layer by layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com