Resource treatment method for household garbage and biochemical sludge

A technology of domestic garbage and biochemical sludge, which is applied in the direction of combustion methods, incinerators, and solid waste removal, can solve problems such as limitations of industrial applications, inapplicability to large-scale applications, and poor quality of carbides. Resource utilization, ease of industrial application, obvious environmental and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] A method for resourceful treatment of domestic garbage and biochemical sludge, comprising six processes of garbage sorting, sludge drying, low-temperature dry distillation, melting and incineration, oil and gas separation and purification, and flue gas treatment. The specific steps of the processing method are as follows:

[0044] 1) Send domestic garbage to the garbage sorting process to sort out usable fuels, and send biochemical sludge to the sludge drying process to produce dried sludge.

[0045] 2) Send usable fuel and dry sludge to the low-temperature carbonization process to produce carbonization oil gas and carbonization residue.

[0046] 3) The dry distillation oil gas and dry distillation residue are respectively sent to the oil and gas separation and purification and melting and incineration processes; the oil and gas separation and purification process separates tar, which is exported and sold as the final product; the glassy solid residue produced in the me...

specific Embodiment approach

[0061] Taking the experimental results of municipal solid waste and biochemical sludge as an example, the specific implementation methods are as follows:

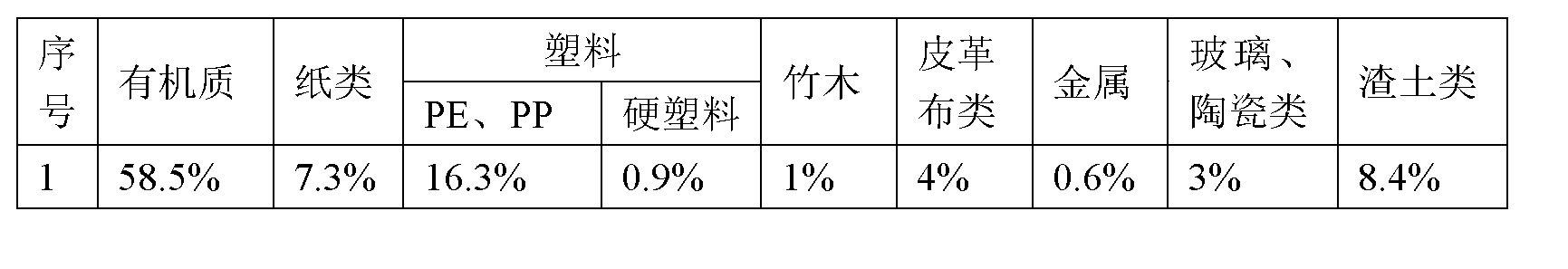

[0062] The composition of a municipal solid waste is shown in the table below:

[0063]

[0064] The composition of biochemical sludge in a certain city is shown in the table below:

[0065] serial number

project

unit

value

Remark

1

Ash

%

52.5

2

moisture content

%

76.9

3

%

47.5

4

mg / kg

not detected

5

10 -4 mg / kg

3.18

6

total chromium

mg / kg

306

7

total mercury

mg / kg

not detected

8

10 -4 mg / kg

1.63

9

total manganese

mg / kg

520

10

Total Nickel

mg / kg

125

12

total lead

m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com