Microbial remediation method for basic chromium pollution soil

A chromium-contaminated soil and microbial remediation technology, applied in the field of chromium-contaminated soil remediation, can solve the problems of less research on remediation, and achieve the effect of reducing bioavailability and good remediation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

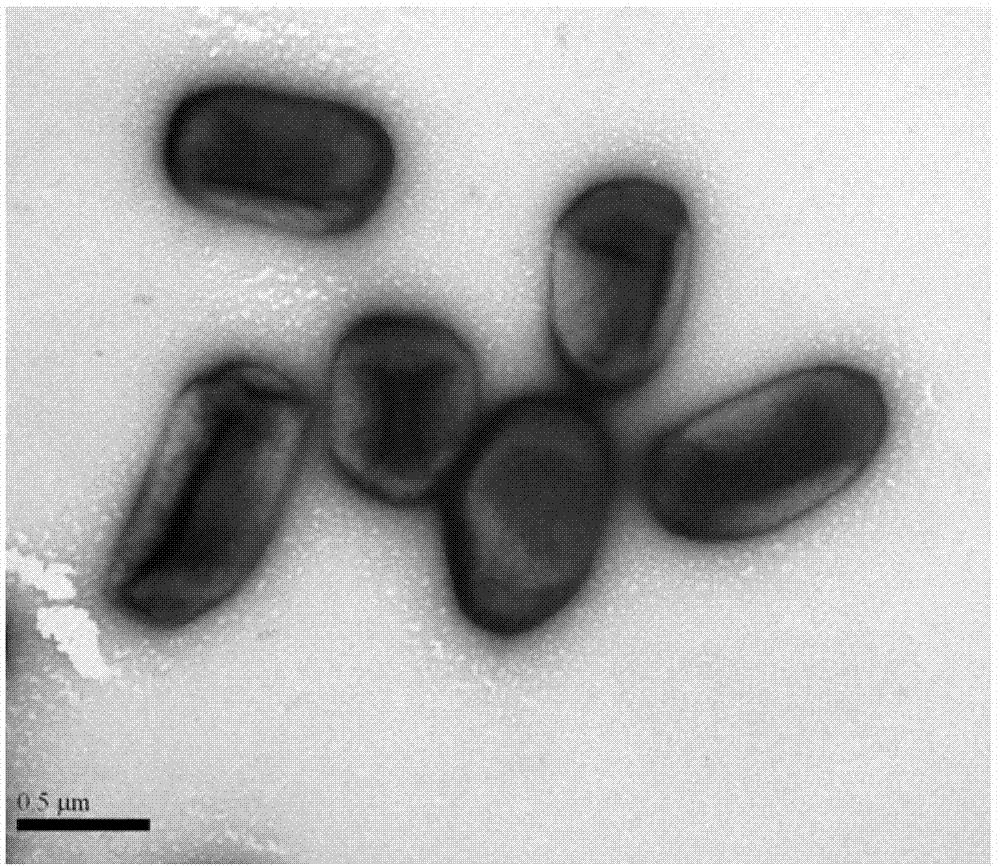

[0023] Embodiment 1: Screening, isolation and identification of bacterial strains of the present invention

[0024] 1. Enrichment: Collect contaminated soil from the chromium slag yard of the former Hongxing Chemical Plant in Hangzhou, weigh 5g of the soil in 50mL of sterilized liquid LB medium (sodium chloride 5gL -1 , yeast extract 5gL -1 , Tryptone 10gL -1 , pH7.0~7.5), 28°C, 160rpm shaking culture.

[0025] 2. Domestication: When the soil suspension changes from the original yellow (Cr(VI) is yellow) to gray-green (Cr(III) is green), take the supernatant and inoculate it into the newly prepared liquid containing Cr(VI) In LB medium, shake culture at 28°C at 160rpm. When the culture medium turns gray-green again, inoculate it into a liquid medium containing a higher Cr(VI) concentration, thereby gradually increasing the Cr(VI) concentration in the medium. VI) concentration, thereby acclimating the target bacterial strain. The Cr(VI) used in the acclimatization process w...

Embodiment 2

[0029] Embodiment 2: the determination of the culture of thalline and inoculum concentration

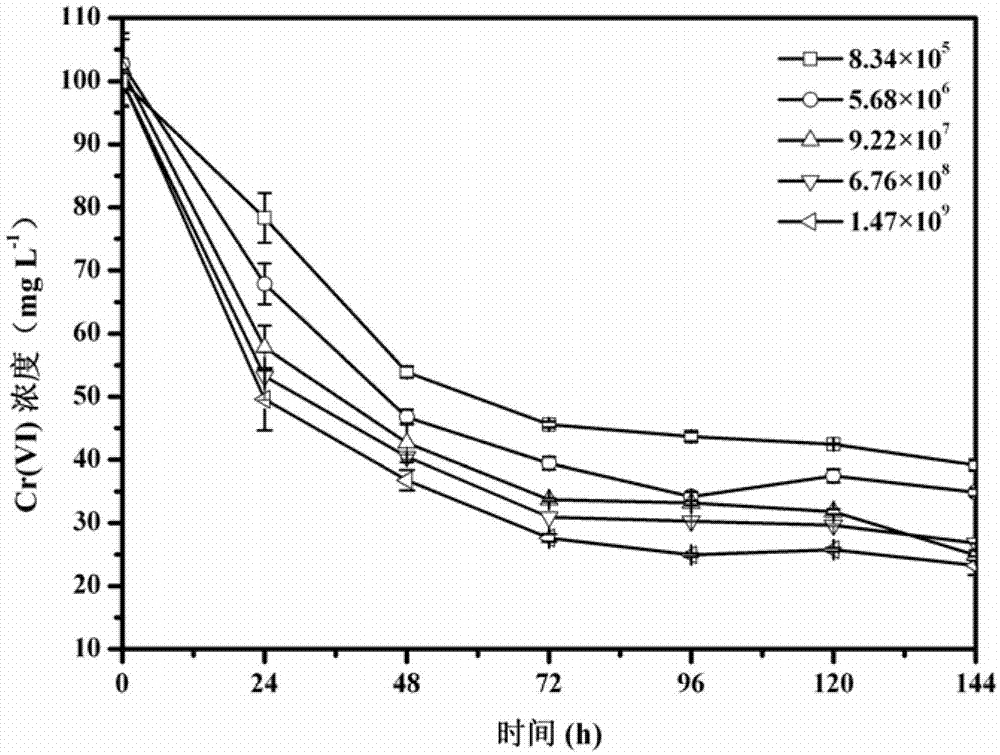

[0030] The strain P. saccharolyticum LY10 was cultivated overnight to the logarithmic growth phase, and inoculated in different proportions to contain 100mgL -1 In the liquid LB medium of Cr(VI), the final concentration of bacteria was 8.34×10 5 , 5.68×10 6 , 9.22×10 7 , 6.76×10 8 , 1.47×109cellsmL -1 , 28°C, shaking culture at 160rpm. Samples were taken at different times, and the supernatant was taken after centrifugation at 10,000 rpm for 10 min to determine the content of Cr(VI).

[0031] The test results show that: when the cell concentration is from 8.34×10 5 cells mL -1 increased to 9.22×10 7 cells mL -1 , with the increase of bacterial concentration, the reduction rate of Cr(VI) gradually accelerated. However, as the cell concentration increased from 6.76×10 8 increased to 1.47×10 9 cells mL -1 , the improvement of Cr(VI) reduction rate is not obvious, the result...

Embodiment 3

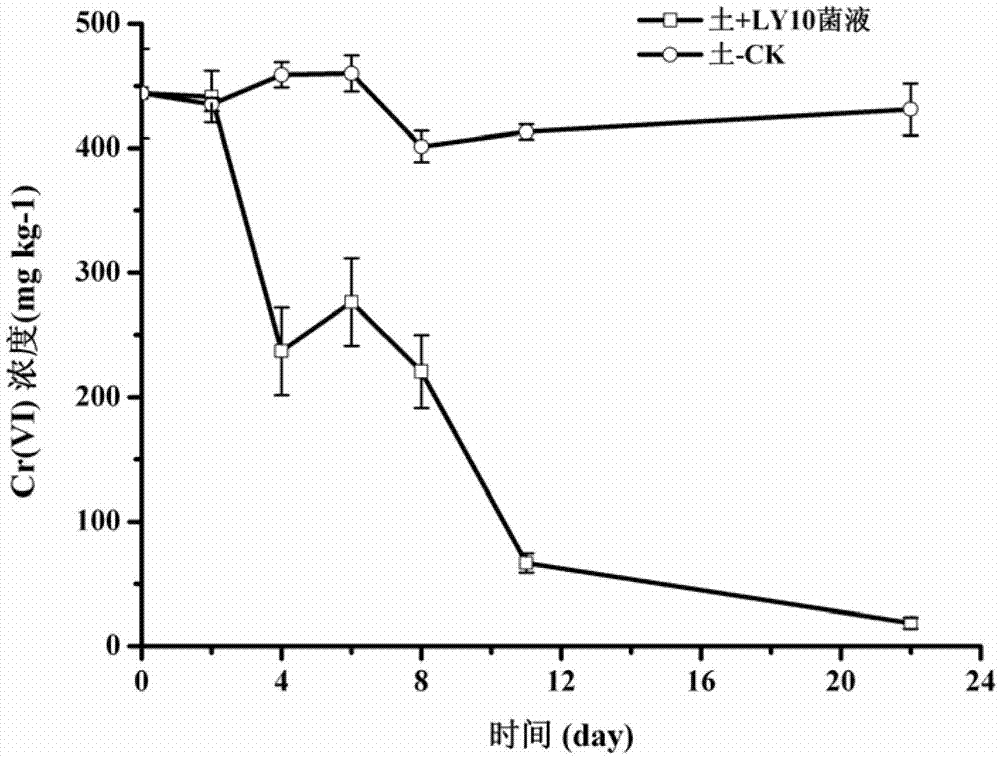

[0032] Embodiment 3: Microbiological remediation of chromium-contaminated soil

[0033] The alkaline chromium-contaminated soil in the chromium slag yard of the former Hongxing Chemical Plant in Hangzhou was collected. The pH of the contaminated soil was 11.3, and the concentration of water-soluble Cr(VI) was 443.9mg kg -1 . The samples were air-dried and ground and passed through a 100-mesh sieve. Take 5g of sieved soil in a 250mL Erlenmeyer flask, add 15mL to pre-culture, and the cell concentration is 10 7 ~10 8 cells mL -1 cultured at 28°C. Supplement 2 mL of fresh liquid LB medium every 5 days to supplement the water evaporated and the nutrients consumed during the restoration process, so as to ensure the nutritional requirements for bacterial growth and maintain the metabolic activity of cells. Samples were taken at different times to determine the Cr(VI) concentration in the soil. After repairing for 22 days, the soil samples were air-dried and finely ground, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com