Nolybdenum disulfide nanometer particle, preparation method and application thereof

A technology of molybdenum disulfide and nano-particles, which is applied in the direction of molybdenum sulfide, chemical instruments and methods, nanotechnology, etc., can solve the problems of high production costs, and achieve the effects of low cost, excellent catalytic performance, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, preparation molybdenum disulfide nanoparticles

[0038] Commercially available micron-sized molybdenum disulfide particles (2 microns in particle size) were mixed with 1-butyl-3-methylimidazolium hexafluorophosphate to obtain a mixture in which micron-sized molybdenum disulfide particles were mixed with 1 The mass ratio of -butyl-3-methylimidazolium hexafluorophosphate is 1:1; then the mixture is placed in a mortar for grinding, and the grinding time is controlled to be 10 hours; then the ground mixture is used The filter membrane with a pore size of 220nm is filtered and separated to obtain molybdenum disulfide nanoparticles.

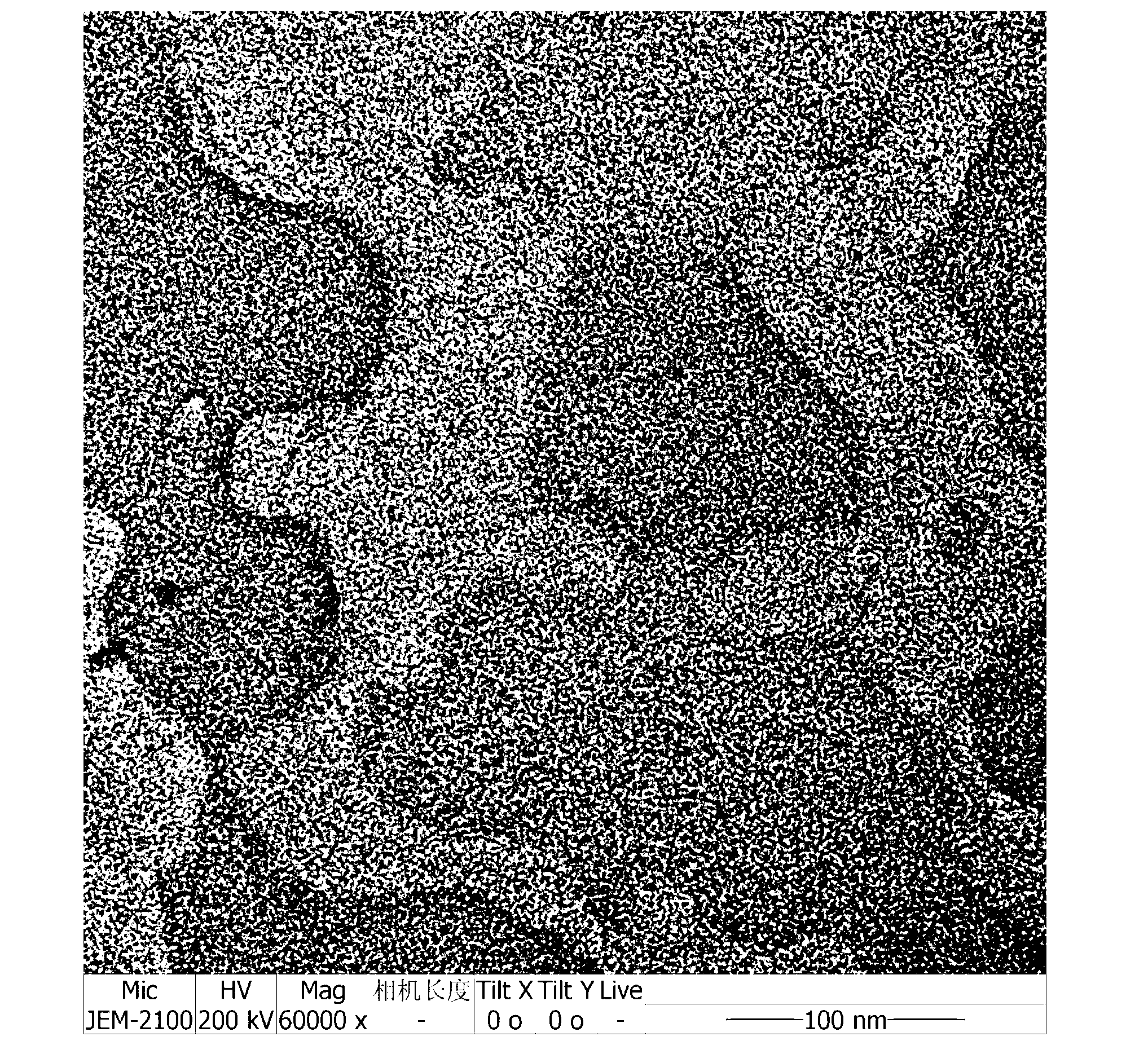

[0039] The transmission electron micrograph of the molybdenum disulfide nanoparticles prepared in this embodiment is as follows: figure 1 As shown in the scanning electron micrograph figure 2 It can be seen from the two figures that the particle size of the prepared molybdenum disulfide nanoparticles is 100-200nm.

Embodiment 2

[0040] Embodiment 2, preparation molybdenum disulfide nanoparticles

[0041]Molybdenite, 1-butyl-3-methylimidazolium hexafluorophosphate and DMSO are mixed to obtain a mixture, in which molybdenite and 1-butyl-3-methylimidazolium hexafluorophosphate and The mass ratio of the DMSO mixture is 1:1000 (the mass ratio of 1-butyl-3-methylimidazolium hexafluorophosphate and DMSO is 4:1); then the mixture is placed in a mortar for Grinding, ultrasonic treatment after grinding, controlling the grinding time to 0.5 hours, and ultrasonic time to 3 hours; then the mixture after grinding and ultrasonic is centrifuged, and the remaining large molybdenum disulfide is removed by centrifugation at 4000rpm, and the above The supernatant was centrifuged at a rotational speed of 8000 rpm, and the precipitate at this rotational speed was collected to obtain molybdenum disulfide nanoparticles.

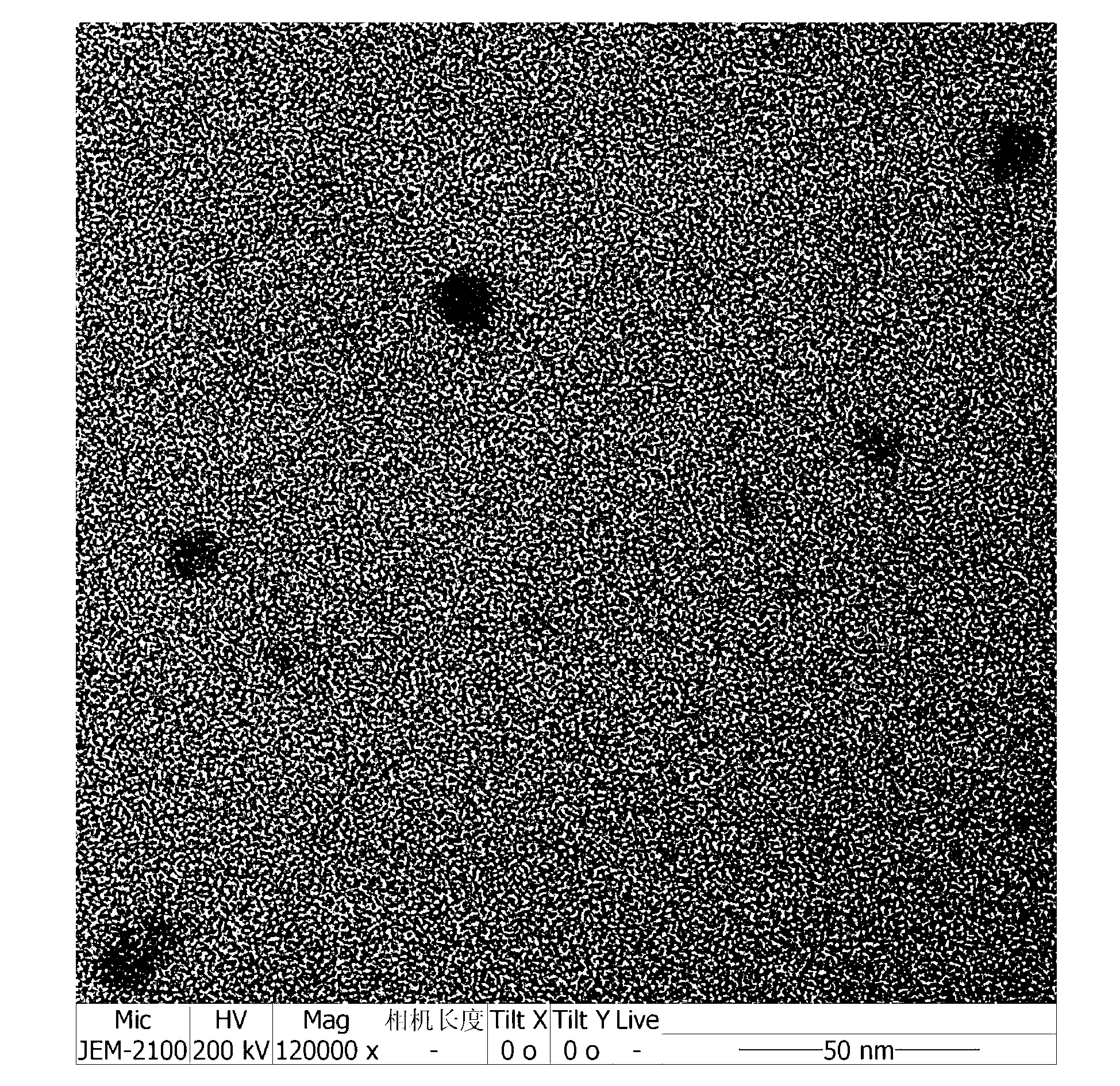

[0042] The transmission electron micrograph of the molybdenum disulfide nanoparticles prepared in this ...

Embodiment 3

[0043] Embodiment 3, preparation molybdenum disulfide nanoparticles

[0044] First, the molybdenite is crushed to obtain a crushed product; then the obtained crushed product is dispersed into water and N-methylpyrrolidone (wherein the mass ratio of water to N-methylpyrrolidone is 1:3) to obtain a mixture, In the mixture, the mass ratio of molybdenite and N-methylpyrrolidone is 1:10000; then the mixture is placed in a plastic cup for ultrasonication, and the ultrasonic time is controlled for 20 hours; then the ground mixture is subjected to Column chromatography separation adopts a silica gel column, the mobile phase is dichloromethane, and the effluent product is collected to obtain molybdenum disulfide nanoparticles.

[0045] The transmission electron micrograph of the molybdenum disulfide nanoparticles prepared in this embodiment is as follows: Figure 5 and Figure 6 It can be seen from the two figures that the particle size of the prepared molybdenum disulfide nanopartic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com