Method for preparing bimatoprost midbody

A technology of mixture and tetrahydrofuran, which is applied in the field of preparation of bimatoprost intermediates, can solve the problems of difficult industrial scale-up production and harsh reaction conditions, and achieve the effects of easy post-processing, simple operation and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

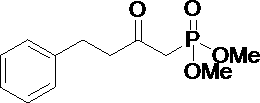

Image

Examples

Embodiment 1

[0029] A method for preparing 2-oxo-4-phenylbutyl dimethyl phosphate, comprising the steps of:

[0030] The first step, prepare lithium diisopropylamide tetrahydrofuran solution

[0031] (1) Under stirring, add 14.6 g of diisopropylamine and 30 mL of anhydrous tetrahydrofuran into a 250 mL reactor and mix uniformly to prepare mixture a;

[0032] (2) Under stirring, gradually add (2.5 M, 98.87 mL) n-butyllithium n-hexane solution dropwise to mixture a in an ice-water bath. After the dropwise addition, control the temperature at 0°C and continue stirring, and stop the reaction after 30 min. Stirring makes diisopropylamide lithium tetrahydrofuran solution;

[0033] The second step, preparation of dimethyl 2-oxo-4-phenylbutyl phosphate

[0034] (1) Under stirring, add 0.112 mol of ethyl 3-phenylpropionate, 200 mL of anhydrous tetrahydrofuran, and 0.118 mol of dimethyl methyl phosphate into a 500 mL single-necked flask and mix uniformly to obtain mixture b;

[0035] (2) Un...

Embodiment 2

[0040] A method for preparing 2-oxo-4-phenylbutyl dimethyl phosphate, comprising the steps of:

[0041] The first step, prepare lithium diisopropylamide tetrahydrofuran solution

[0042] (1) Under stirring, add 292 g of diisopropylamine and 5 L of anhydrous tetrahydrofuran into a 10 L reactor and mix uniformly to prepare mixture a;

[0043] (2) Under stirring, gradually add (2.5 M, 2 L) n-butyllithium cyclohexane solution dropwise to mixture a in an ice-water bath. After the dropwise addition, control the temperature at 0°C and continue stirring for 100 min. Stop stirring to obtain diisopropylamide lithium tetrahydrofuran solution;

[0044] The second step, preparation of dimethyl 2-oxo-4-phenylbutyl phosphate

[0045] (1) Under stirring, add 2.24 mol of ethyl 3-phenylpropionate, 4L of anhydrous tetrahydrofuran, and 2.42 mol of dimethyl methyl phosphate into a 20L reactor and mix uniformly to prepare mixture b;

[0046] (2) Under stirring, gradually add the diisopropy...

Embodiment 3

[0051] A method for preparing 2-oxo-4-phenylbutyl dimethyl phosphate, comprising the steps of:

[0052] The first step, prepare lithium diisopropylamide tetrahydrofuran solution

[0053] (1) Under stirring, add 58.4 g of diisopropylamine and 120 mL of anhydrous tetrahydrofuran into a 500 mL reactor and mix uniformly to prepare mixture a;

[0054] (2) Under stirring, gradually add (2.5 M, 395.5 mL) n-butyllithium n-hexane solution dropwise to mixture a under an ice-water bath. After the dropwise addition, control the temperature at 0°C and continue stirring for 60 min. Stop stirring to obtain diisopropylamide lithium tetrahydrofuran solution;

[0055] The second step, preparation of dimethyl 2-oxo-4-phenylbutyl phosphate

[0056] (1) Under stirring, add 0.448 mol of ethyl 3-phenylpropionate, 800 mL of anhydrous tetrahydrofuran, and 0.472 mol of dimethyl methyl phosphate into a 3L single-necked flask and mix uniformly to obtain mixture b;

[0057] (2) Under stirring, gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com