Automobile engine fluorosilicone seal ring sizing material and preparation method thereof

A technology for automotive engines and sealing rings, applied in the field of synthetic rubber, can solve problems such as high labor intensity, low production efficiency, tearing and poor oil resistance, and achieve the effects of improving overall performance, reducing production costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

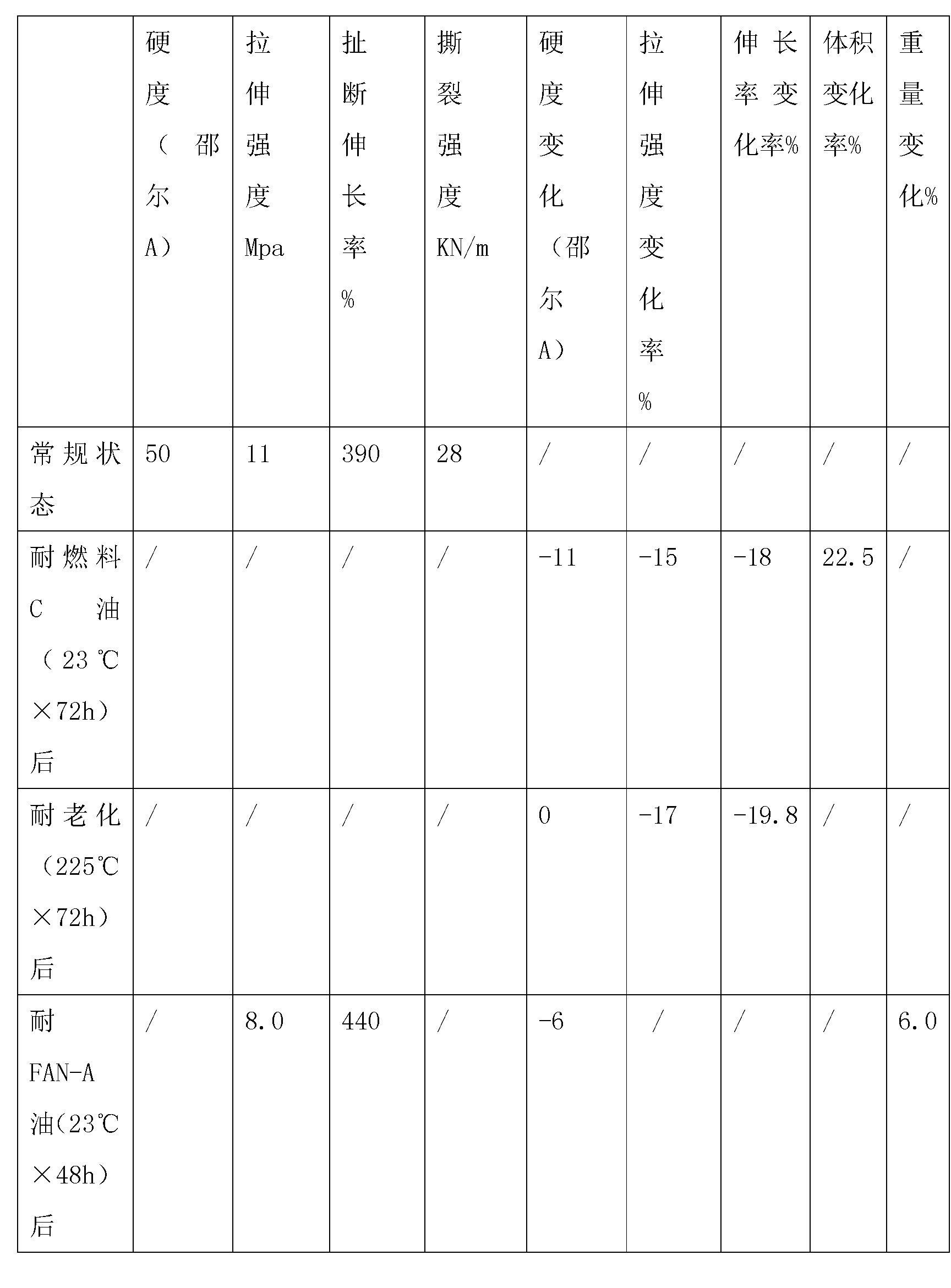

Image

Examples

Embodiment Construction

[0020] The preparation of fluorosilicone sealing ring compound for automobile engine first weighs 75kg of fluorosilicone rubber, 22kg of styrene-butadiene rubber, 5kg of methyl vinyl silicone rubber, 0.6kg of isooctyl dithioglycolate, 0.6kg of di-n-octyltin, 5kg of zinc oxide, hard Zinc fatty acid 0.8kg, triethylene glycol diisocaprylate 7kg, hydroxyfluorosilicone oil 0.6kg, paraffin 0.4kg, silane coupling agent KH-550 1.5kg, anti-aging agent AW 1.5kg, anti-aging agent 4010NA 0.2kg, modified Sepiolite 14kg, carbon black N330 35kg, modified iron tailings 15kg, rapeseed oil 22kg, vulcanizing agent BP0.6kg, accelerator TMTD0.6kg, accelerator M0.3kg, ferrocene 1.5kg, fatty alcohol polyoxygen Sodium vinyl ether sulfate 0.9kg, diethanolamide 0.9kg,

[0021] The preparation method comprises the following steps:

[0022] (1) Preparation of modified sepiolite:

[0023] Soak the sepiolite with 15-20% hydrochloric acid for 1-2 hours, wash with water until neutral, after drying, add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com