Soil solidifier and soil solidification method

A technology of soil curing agent and fly ash, which is applied in the field of civil engineering, can solve the problems of not being able to meet the development needs of engineering construction, insufficient water stability of soil curing agent, and compressive strength not reaching industry standards, etc., to shorten the construction period, Good water and moisture resistance, fast setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

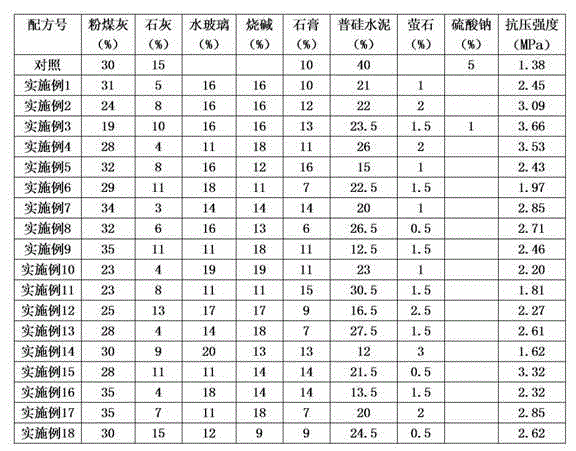

Examples

Embodiment 19

[0049] Example 19: Maximum Dry Density and Compressive Strength Tests for Soil Stabilizers

[0050] (1) Soil maximum dry density experiment

[0051] 1. according to the preparation method of formula described in embodiment 1 and curing agent, prepare soil curing agent;

[0052] ②Add the weighed curing agent to the soaked soil sample, fully mix it with a stirrer to a uniform state, and place it for 12 hours;

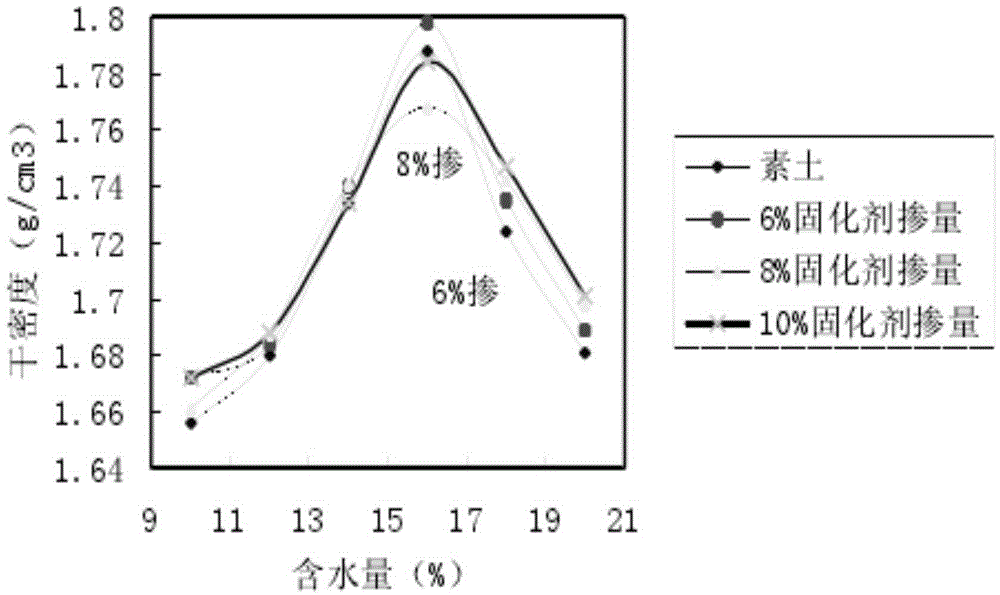

[0053] ③According to the requirements of TO804-94 in JTJ057-94, select the heavy-duty test method, and prepare soil samples according to the water content of 10%, 12%, 14%, 16%, 18%, and 20% respectively; use the instrument to detect the soil of the test piece dry density; and dot plot soil dry density-water content diagram, see figure 1 .

[0054] ④ by figure 1 The optimal soil moisture content can be found under the maximum dry density of soil, and the maximum dry density of soil is 1.80g / cm 3 , the optimal moisture content is 15.5%.

[0055] (2) Compressive str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com