Preparation method for improving productivity of mitomycin C

A kind of technology of mitomycin and yield, applied in the field of preparation of improving mitomycin C yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

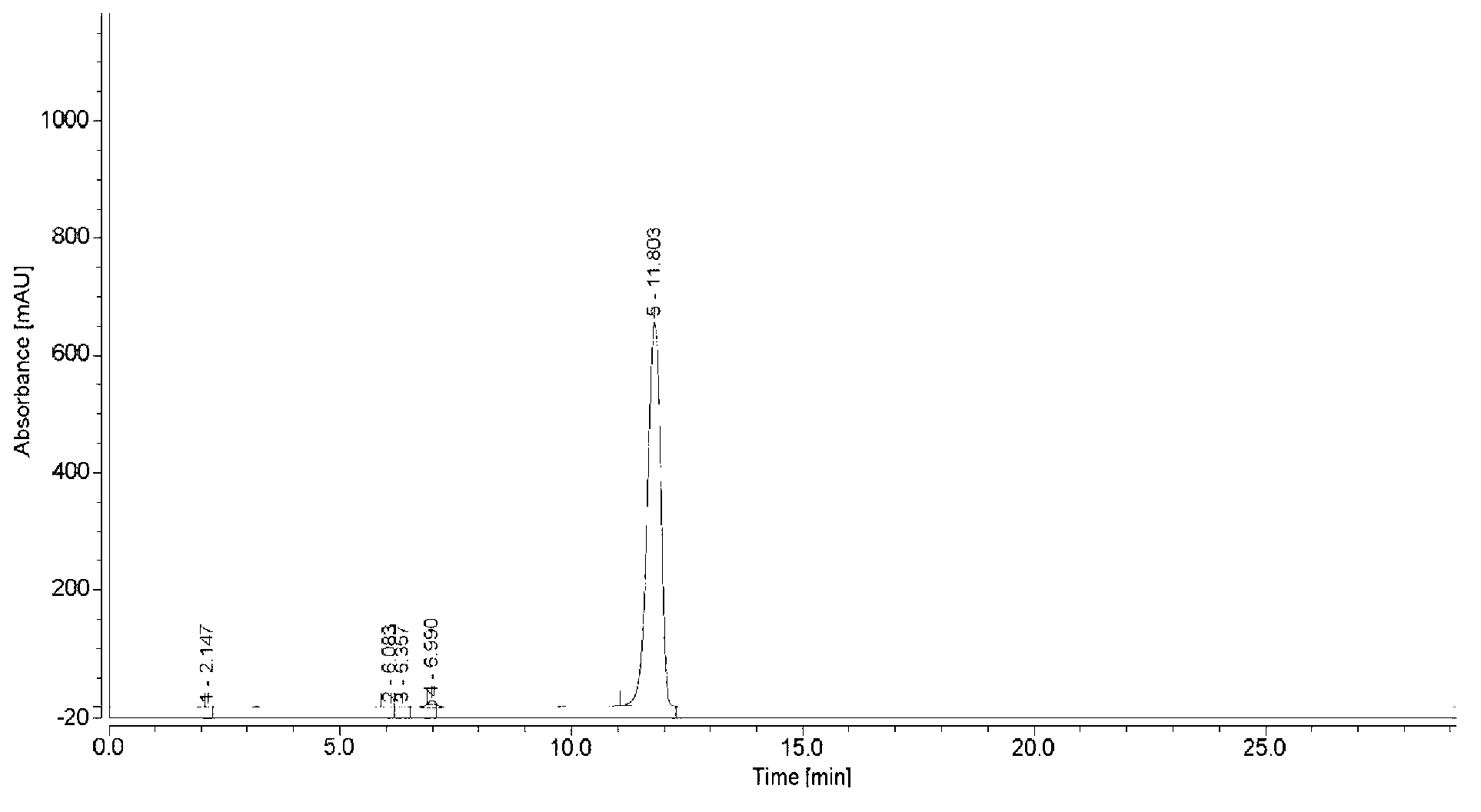

Image

Examples

Embodiment 1

[0020] The mitomycin C-producing strain used in this example is Streptomyces capitis ATCC27422, and the culture medium can be a common medium suitable for cultivating actinomycetes. The actual slant medium used in this example consists of 1.0% starch , calcium carbonate 0.1%, potassium nitrate 0.1%, magnesium sulfate 0.05%, sodium chloride 0.05%, potassium dihydrogen phosphate 0.03%, asparagine 0.002%, bran 2.0%, agar 2.0%, the rest is water PH natural ( The above percentages are all percentages by mass). Sterilize at 120°C for 30 minutes, pave it into a solid slope, inoculate the bacteria on the slope, and cultivate it at 28±2°C for 8 days, inoculate the well-grown slope bacteria on the 120°C sterilized surface by digging blocks. In the 30-minute seed medium, the composition of the seed medium is 1% glucose, 3% starch, 2.0% bean cake powder, 0.5% corn steep liquor, 0.1% sodium chloride, 0.01% potassium dihydrogen phosphate, 0.2% corn oil, and the rest Adjust the pH of the wa...

Embodiment 2

[0024] The strain that produces Mitomycin C used in this example is Streptomyces capitis ATCC27422, and its slant medium consists of starch 1.0%, calcium carbonate 0.1%, potassium nitrate 0.1%, magnesium sulfate 0.05%, sodium chloride 0.05%, Potassium dihydrogen phosphate 0.03%, asparagine 0.002%, bran 2.0%, agar 2.0%, and the rest is water with natural pH. Sterilize at 120°C for 30 minutes, spread it into a solid slope, inoculate the bacteria on the slope, and cultivate it at 28±2°C for 6 days, inoculate the well-grown slope bacteria on the 120°C sterilized surface by digging blocks. In the 30-minute seed medium, the composition of the seed medium is 2% glucose, 1% starch, 1.5% bean cake powder, 0.5% corn steep liquor, 0.1% sodium chloride, 0.01% potassium dihydrogen phosphate, 0.2% corn oil, and the rest Adjust the pH of the water to 7.00. Rotate and shake at 28°C for 48 hours after inoculation, and then use as seeds for fermentation. Add citrulline, arginine composite pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com