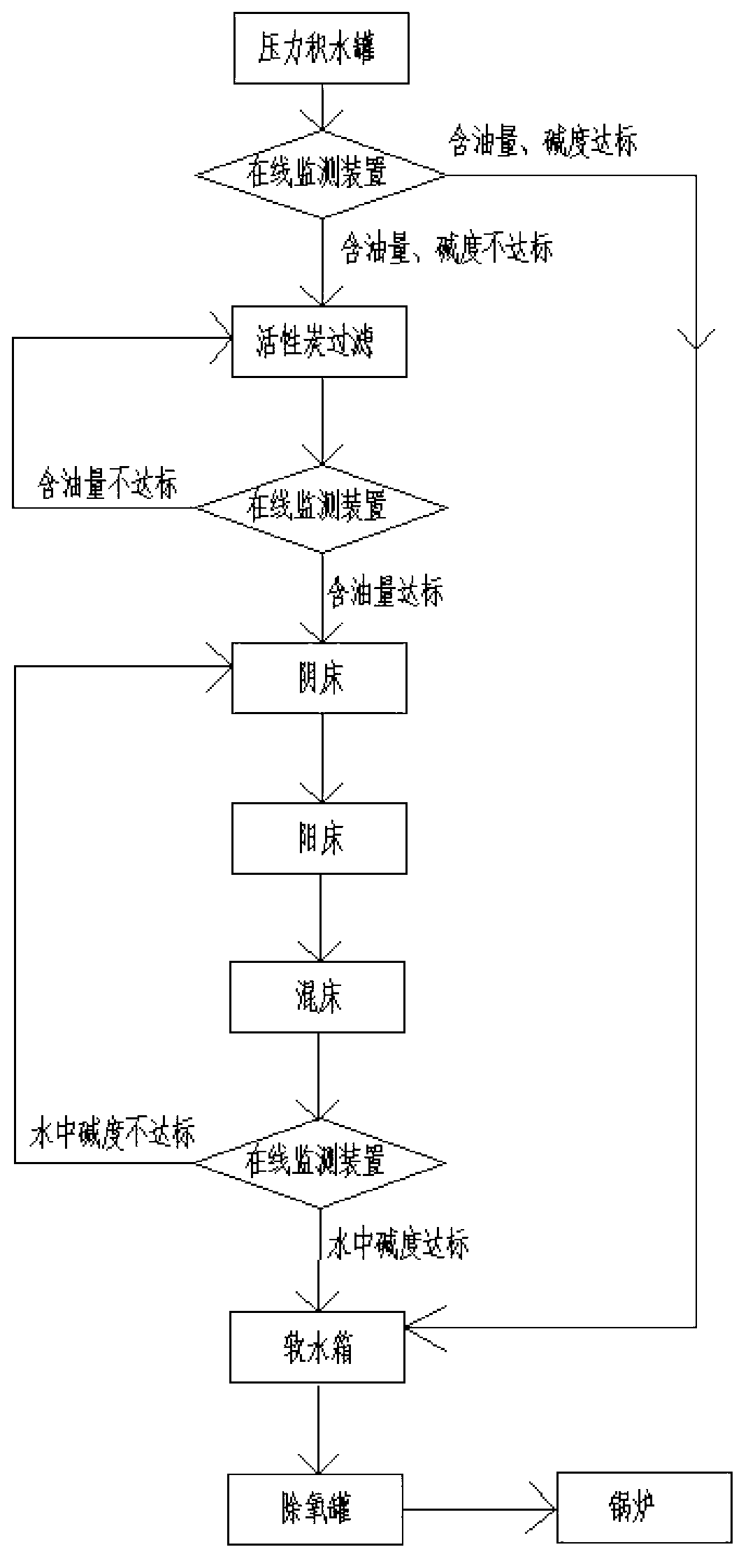

Boiler condensed water recovery process

A technology for condensed water and boilers, applied in the field of boiler condensed water recovery technology, can solve the problems of boiler equipment oxidation, heating medium leakage pollution, iron pollution, etc., and achieve the effects of saving energy, improving recycling rate, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments thereof. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

[0024] Theoretically speaking, steam condensed water is formed by the condensation of steam, and the water quality is extremely pure. However, in practical applications, due to various reasons, condensed water will contain some pollutants. Only by clarifying the cause of the pollution and taking measures to prevent and treat it In combination, the pollution of condensed water can be effectively prevented, thereby avoiding the waste of water resources and heat.

[0025] Pollution factors in boiler condensed water are roughly divided into two types: metal pollutants and organic pollutants. The metal pollutants mainly exist in condensed water in the form of ions, such as Fe2+, Fe3+,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com