Negative pole active material, preparation method thereof and lithium-ion battery

A technology of negative electrode active materials and properties, which is applied in the field of negative electrode active materials and their preparation, can solve the problem that negative electrode active materials are difficult to have high specific capacity and cycle performance, and achieves structural stability, reducing surface energy, and inhibiting agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Specifically, the preparation method of the negative electrode active material of the present invention comprises the following steps:

[0029] Step 1: Surface treatment of graphite;

[0030] This step is a preferred step, and the graphite with oxygen-containing active groups on the surface is obtained by surface treatment of the graphite. The graphite can be selected from graphite materials known in the art, and preferably, spherical graphite or flake graphite can be selected. The surface treatment is specifically immersing graphite in acid or alkali for acidification or alkalization treatment. On the one hand, the surface treatment of graphite can remove incompatible groups on the graphite surface, such as hydrophilic and oil-repellent groups; on the other hand, it can improve the flatness of the graphite surface, thereby improving the adhesion between stannate and graphite. The conditions for the acidification or alkalization treatment are as follows: under the con...

Embodiment 1

[0063] This example is used to illustrate the negative electrode active material disclosed in the present invention and its preparation method;

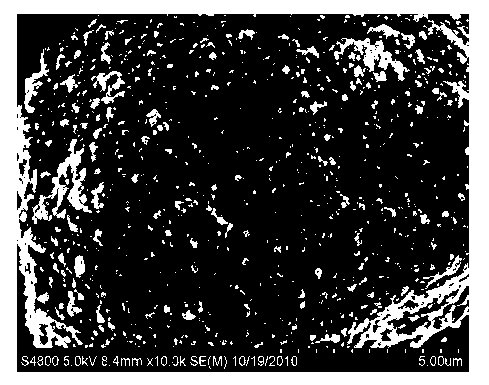

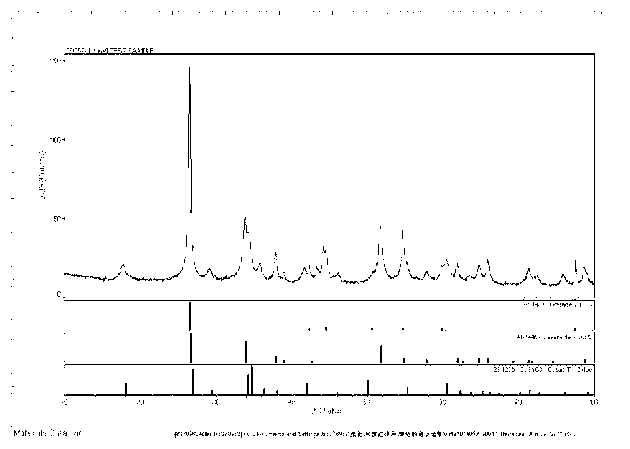

[0064] 1) Mix 100g of graphite G with organic polymer polyvinyl alcohol 2000, the mass ratio is 10:1, and take 21.3g of Na 2 SnO 3 Dissolve in water to make a solution, add it to the above mixture, mix and stir to obtain a mixed solution with a total volume of 2000ml, place the mixed solution in a volumetric flask and put it in a water bath and heat it up to 85°C and keep stirring, take 5g of EDTA and add it Ionized water was made into a 250ml solution and added to the volumetric flask. The pH value of the solution was adjusted to 10 with NaOH, and stirred at a constant temperature of 85°C for 2 hours to obtain a mixed system; then 12.9 grams of CoCl was taken. 2 Dissolve in 500ml of deionized water and slowly drop it into a volumetric flask for reaction to generate water-insoluble cobalt stannate (CoSnO 3 ), until the precipitatio...

Embodiment 2

[0067] This example is used to illustrate the negative electrode active material disclosed in the present invention and its preparation method;

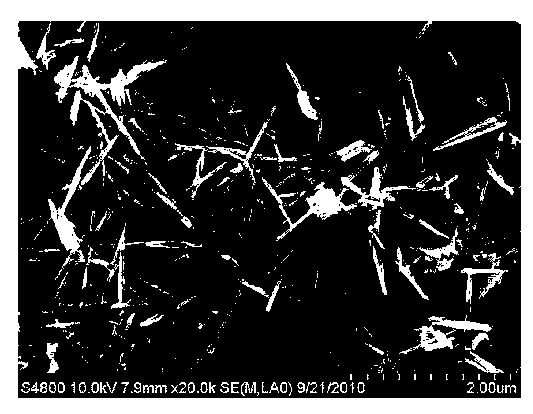

[0068] 1) Pour 500g of sulfuric acid with a concentration of 67% into a glass container, place the glass container in a water bath at 80°C, add 50g of graphite G after 30 minutes, keep warm and stir for 2.5 hours; then deionize the graphite suspension with Washing with water repeatedly until the pH value of the suspension is 7-8, and then baking the filtered graphite at 60 °C for 12 hours to obtain surface-functionalized graphite OG;

[0069] 2) Mix 100g of surface functionalized graphite OG with organic polymer polyvinyl alcohol 2000, the mass ratio is 10:1, and at the same time take 21.3g of Na 2 SnO 3 Dissolve in water to make a solution, add it to the above mixture, mix and stir to obtain a mixed solution with a total volume of 2000ml, place the mixed solution in a volumetric flask and put it in a water bath and heat it up to 85...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com