Multi-stage continuous refiner set and application of the multi-stage continuous refiner set in clean preparation of layer-like composite metal hydroxide

A hydroxide, layered composite technology, applied in the preparation of oxide/hydroxide, grain processing, etc., can solve the problems of shortened reaction time, large product particle size, long reaction time, etc. The effect of particle size reduction and particle size reduction of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

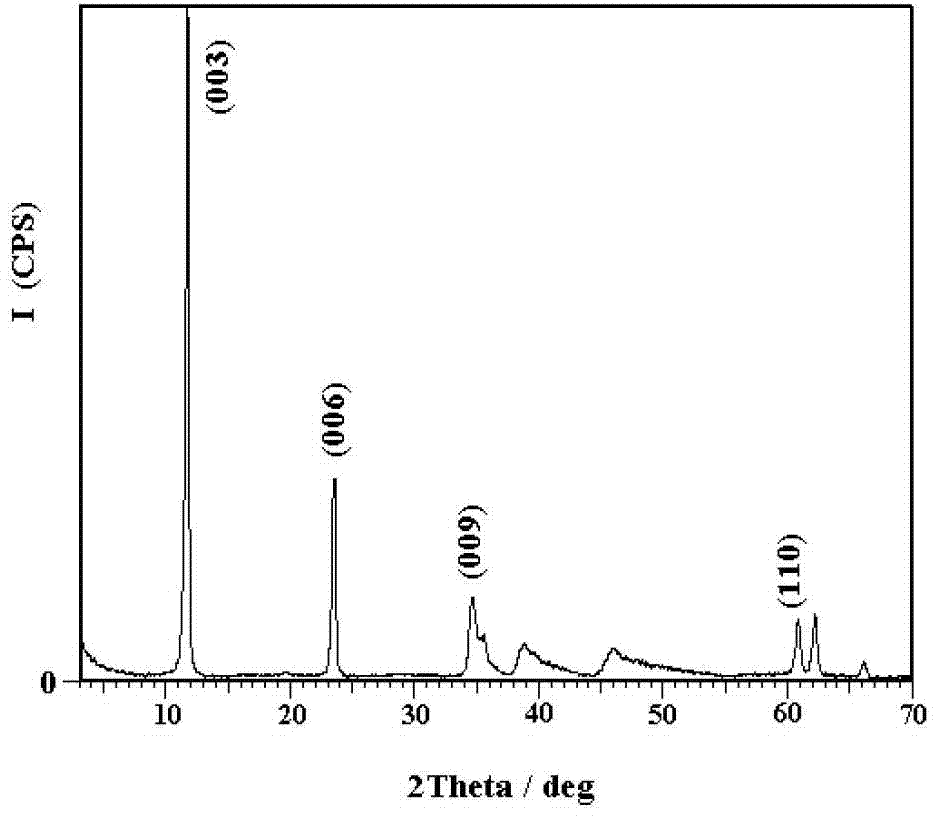

[0019] Step A: Mg(OH) 2 and Al(OH) 3 According to Mg 2+ / Al 3+ Mix at a molar ratio of 2:1, take 1kg of the mixture and place it in 9kg of deionized water, first pass the raw material through a sand mill for rough grinding, then pass through a colloid mill with a slit of 35 μm for the first stage of fine grinding, and finally pass through the slit The second level of fine grinding is carried out for a 15μm colloid mill,

[0020] Step B: transfer the ground raw material in step A to a reactor with a reflux device, and feed CO at a rate of 1000ml / min 2 Gas, heat up to 100°C under stirring conditions, reflux for 4 hours, stop aeration to end the reaction, centrifuge the obtained product and dry it at 70°C for 8 hours to obtain the molecular formula Mg 4 Al 2 (OH) 12 CO 3 4H 2 O layered composite metal hydroxide products.

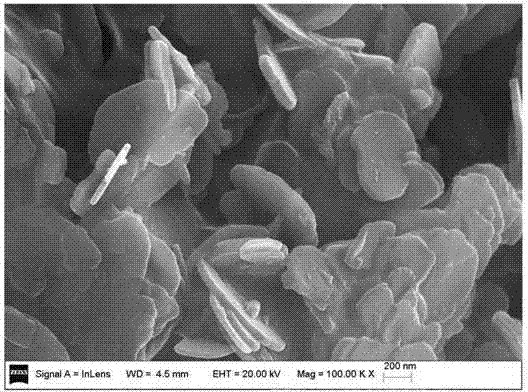

[0021] The crystal structure of the sample was characterized by XRD-6000 X-ray powder diffractometer from Shimadzu Corporation, Japan. figure 1is the...

Embodiment 2

[0024] Step A: Ni(OH) 2 and Fe(OH) 3 According to Ni 2+ / Fe 3+ Mix with a molar ratio of 4:1, take 5kg of the mixture and place it in 90kg of deionized water, first pass the raw material through a sand mill for rough grinding, then pass through a colloid mill with a slit of 30 μm for the first stage of fine grinding, and finally pass through the slit Carry out second-stage fine grinding for a 15μm colloid mill;

[0025] Step B: transfer the ground raw materials in step A into a reactor with a reflux device, add 0.58kg of terephthalic acid, heat up to 100°C under stirring conditions, and reflux for 1 day, centrifuge the obtained product at 70°C Dry for 8 hours to obtain the molecular formula Ni 8 Fe 2 (OH) 20 (C 8 h 4 o 4 )·4H 2 Layered composite metal hydroxides of O.

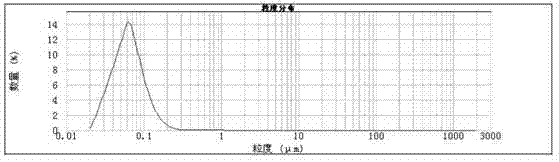

[0026] The morphology of the samples was observed with a HITACHI S-3500N scanning electron microscope (SEM). figure 2 It is the SEM photo of the sample prepared in embodiment 2, as seen from the fi...

Embodiment 3

[0028] Step A: Zn(OH) 2 , Mg(OH) 2 and Al(OH) 3 According to Zn 2+ :Mg 2+ :Al 3+ Mix with a molar ratio of 1:3:2, take 20kg of the mixture and place it in 80kg of deionized water, first pass the raw material through a sand mill for rough grinding, then pass through a colloid mill with a slit of 35 μm for the first stage fine grinding, and finally pass through A colloid mill with a slit of 10 μm is used for the second stage fine grinding;

[0029] Step B: Transfer the ground raw materials in step A into a closed reactor with a stirring device, add 40kg of dry ice, heat up to 150°C under stirring, react for 12 hours, centrifuge the obtained product and dry it at 70°C for 8 hours , to get the molecular formula ZnMg 3 Al 2 (OH) 12 CO 3 4H 2 Layered composite metal hydroxides of O.

[0030] The elemental content of the samples was analyzed by a Shimadzu ICPS-7500 elemental analyzer. Elemental analysis of the sample prepared in Example 3 shows that the Zn:Mg:Al=1:3:2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com