Method for self-assembling carbon nano tubes in water by regulating temperature to guide polymer to modify carbon nano tubes

A technology of carbon nanotubes and acidified carbon nanotubes, applied in the fields of carbon compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of not reflecting the characteristics of one-dimensional materials, and achieve the effect of simple steps and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

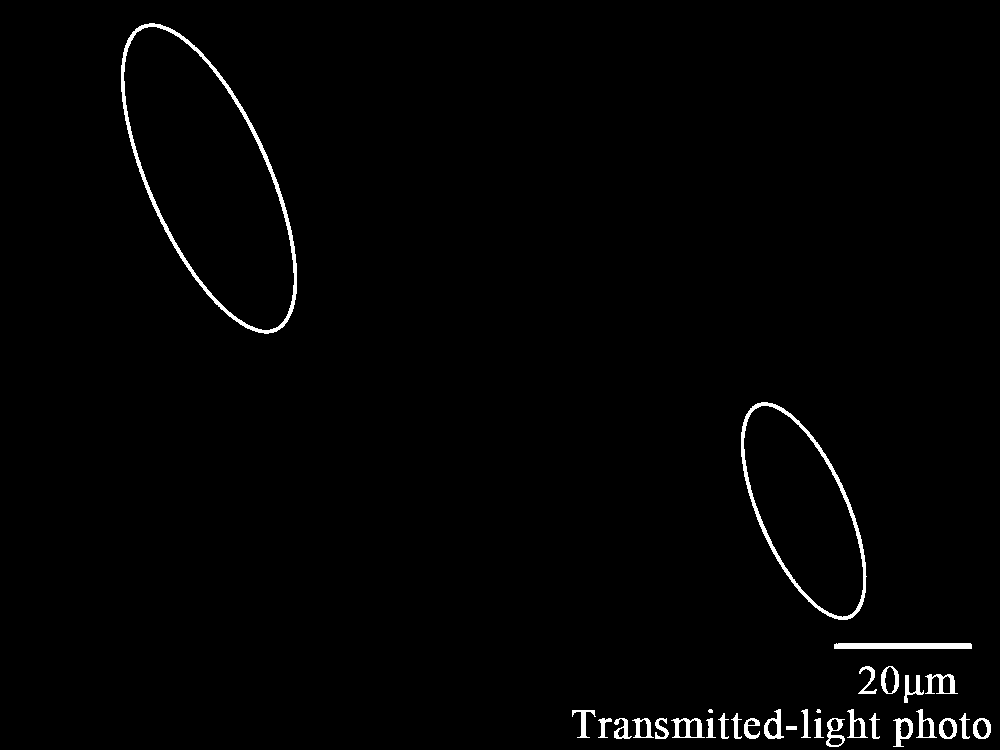

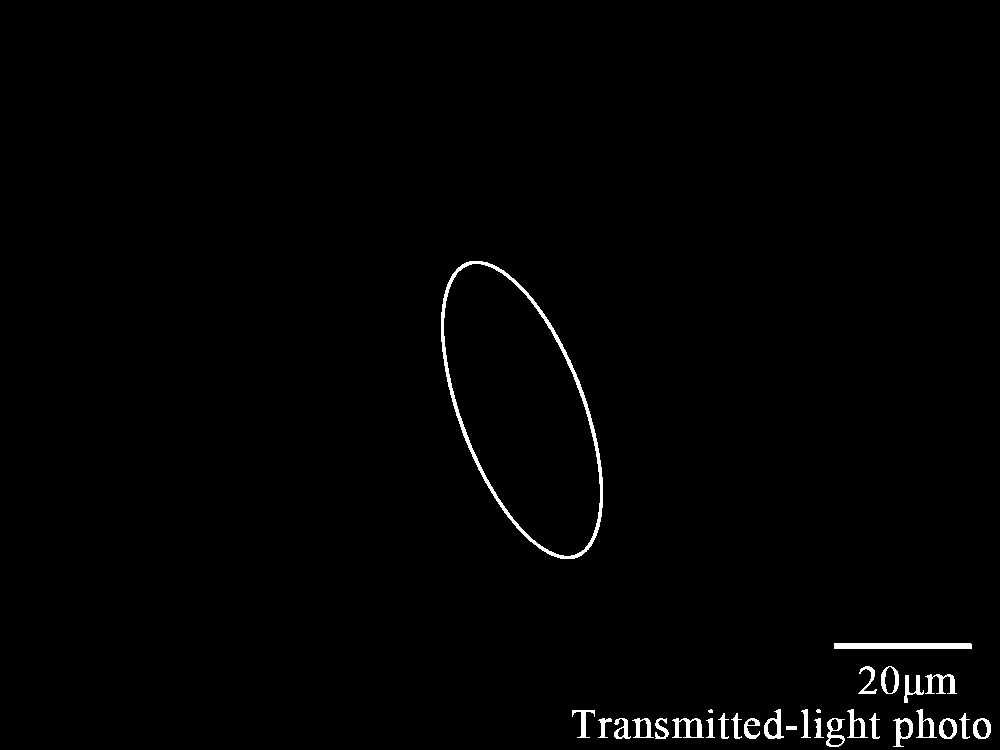

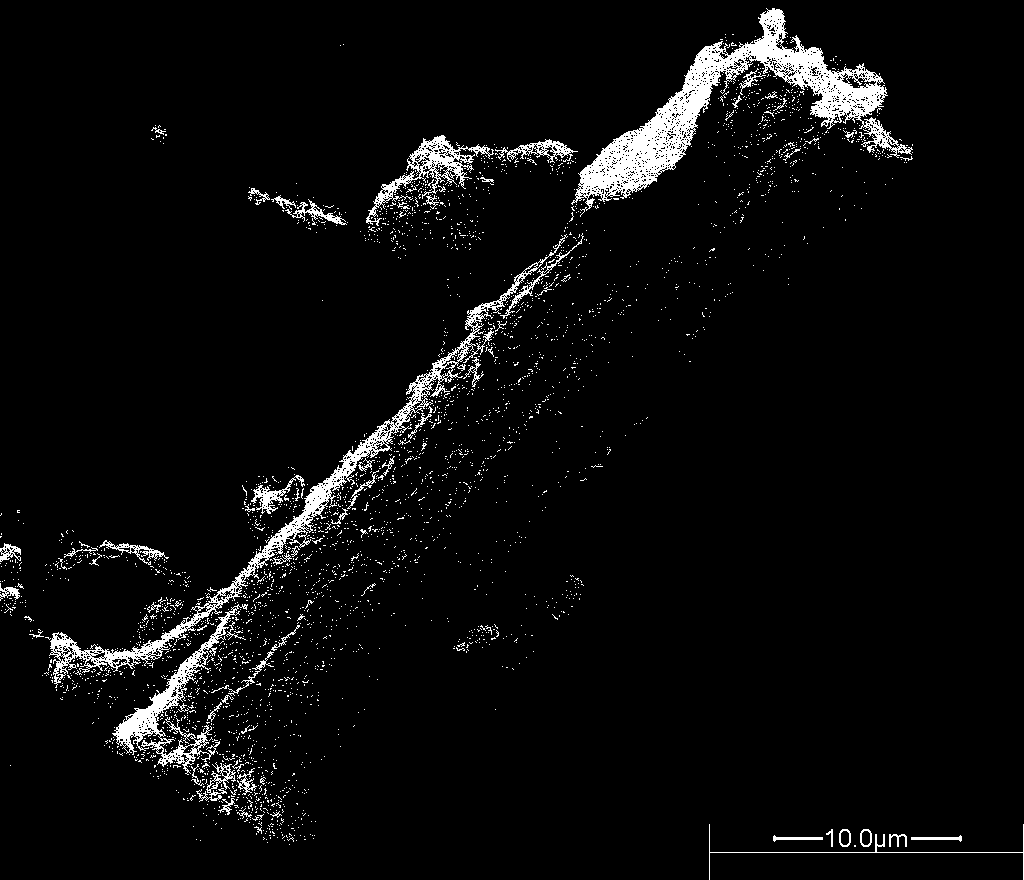

[0026] Example 1: Add 500 mg of multi-walled carbon nanotubes (tube outer diameter ≈ 15 nm) prepared by arc discharge method into 150 ml of concentrated nitric acid (65%), ultrasonically disperse for 10 minutes, and oxidize at 60° C. for 12 hours. After the reaction was completed, it was diluted and washed with deionized water, and separated by filtration until the filtrate was neutral. Vacuum drying at 50°C for 24 hours to obtain acidified carbon nanotubes; add 200 mg each of acidified carbon nanotubes and methyl cellulose to 50 ml of water, ultrasonically disperse for 10 minutes, and adsorb at 40°C for 48 hours to obtain carbon nanotubes with high methylcellulose adsorption capacity. After the adsorption, the temperature was raised to 80° C., centrifuged at a speed of 10,000 r / min for 30 minutes, and a self-assembled carbon nanotube was obtained at the bottom of the container. The length of the carbon nanotube self-assembled tube bundle is 25-40 μm, and the diameter is 3-6 μ...

Embodiment 2

[0027] Example 2: Add 500 mg of multi-walled carbon nanotubes (tube outer diameter ≈ 15 nm) prepared by chemical vapor deposition into 150 ml of concentrated nitric acid (65%), ultrasonically disperse for 10 minutes, and oxidize at 60° C. for 12 hours. After the reaction was completed, it was diluted and washed with deionized water, and separated by filtration until the filtrate was neutral. Vacuum dry at 50°C for 24 hours to obtain acidified carbon nanotubes; add 200 mg each of acidified carbon nanotubes and hydroxypropyl cellulose into 50 ml of ethanol, disperse with ultrasonic waves for 10 minutes, and absorb at 40°C for 48 hours. After being diluted and washed with ionized water and dispersed by ultrasonic waves, centrifuged again, repeated twice, to obtain carbon nanotubes with high adsorption capacity of hydroxypropyl cellulose. Disperse it in water, raise the temperature to 60°C, and let it stand for 24 hours, and the self-assembly of carbon nanotubes can be collected a...

Embodiment 3

[0028] Example 3: Add 200 mg of multi-walled carbon nanotubes prepared by laser evaporation (tube outer diameter ≈15 nm) and hydroxyethyl cellulose into 50 ml of methanol, ultrasonically disperse for 10 minutes, and absorb at 55° C. for 48 hours. After centrifugation, the bottom sediment was diluted and washed with deionized water and dispersed by ultrasonic waves, and then centrifuged again, repeated 10 times, to obtain carbon nanotubes with low hydroxyethyl cellulose adsorption capacity. Disperse it in water, lower the temperature to 20° C., and let it stand for 48 hours. The self-assembly of carbon nanotubes can be collected at the bottom of the container. The self-assembled body has a length of 25-40 μm and a diameter of 3-6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com