A scandia-stabilized zirconia solid solution and its preparation process

A preparation process, zirconia technology, applied in the field of zirconia solid solution and its preparation process, can solve the problems of high ionic conductivity, low activation energy, etc., and achieve the effect of small specific surface area, good sintering activity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

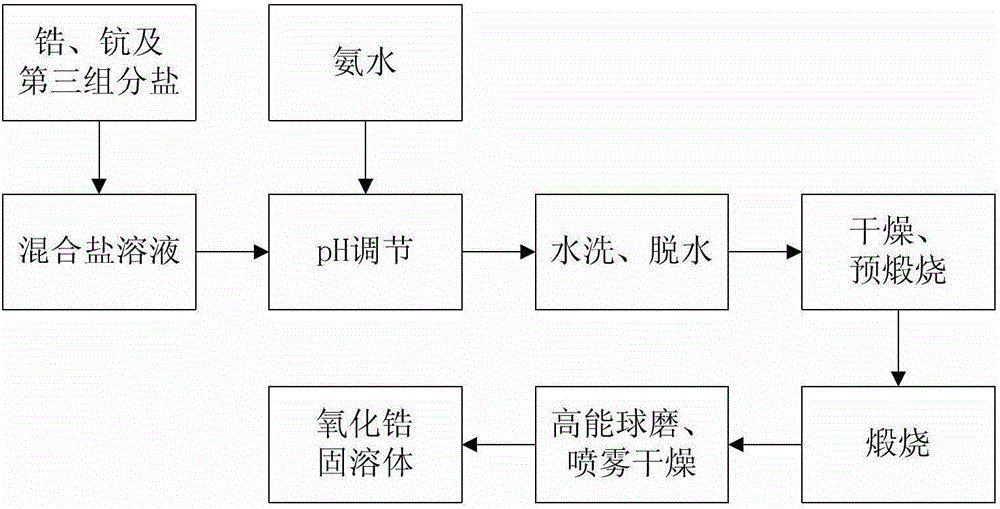

[0023] A preparation process of scandium oxide-stabilized zirconia solid solution, the specific steps are:

[0024] 1) ZrOCl 2 ·8H 2 O2 2.90Kg, ScCl 3 ·6H 2 O4.14Kg and CeCl 3 ·7H 2 0.30Kg is made into mixed aqueous solution;

[0025] 2) Add ammonia water for co-precipitation and adjust the pH value to 7.70;

[0026] 3) Wash with water, control Cl - Content less than 100ppm, centrifugal dehydration;

[0027] 4) The dehydrated powder is dried at 150°C;

[0028] 5) The dried powder is pre-calcined at 400°C to obtain primary powder;

[0029] 6) The primary powder is calcined in an oxidizing atmosphere, the conditions are: the heating rate is 1°C / min, the temperature is raised to 800°C, and kept for 30 hours;

[0030] 7) The calcined powder is milled by a vertical ball mill with high-energy ball milling, adding 50 g of modified ammonium polyacrylate, and milling to a medium particle size of D 50 0.40-0.60μm, specific surface area=10.50±1.00m 2 / g;

[0031] 8) Spray dr...

Embodiment 2

[0034] A preparation process of scandium oxide-stabilized zirconia solid solution, the specific steps are:

[0035] 1) Zr(NO 3 ) 4 ·5H 2 O29.60Kg, Sc (NO 3 ) 3 ·H 2 O3.95Kg and Ce (NO 3 ) 3 ·5H 2 0.99Kg is made into mixed solution;

[0036] 2) Add ammonia water for co-precipitation and adjust the pH value to 9.00;

[0037] 3) Water washing, control NO 3 - Ion content is less than 100ppm, centrifugal dehydration;

[0038] 4) The dehydrated powder is dried at 200°C;

[0039] 5) The dried powder is pre-calcined at 500°C to obtain primary powder;

[0040] 6) The primary powder is calcined in an oxidizing atmosphere, the conditions are: the heating rate is 3°C / min, the temperature is raised to 900°C, and kept for 20 hours;

[0041] 7) The calcined powder is milled by a vertical ball mill with high-energy ball milling, adding 50 g of modified ammonium polyacrylate, and milling to a medium particle size of D 50 0.40-0.60μm, specific surface area=10.50±1.00m 2 / g;

[...

Embodiment 3

[0045] A preparation process of scandium oxide-stabilized zirconia solid solution, the specific steps are:

[0046] 1) Zr(SO 4 ) 2 4H 2 O23.39Kg, Sc 2 (SO 4 ) 3 ·6H 2 O3.81Kg and Ce(SO 4 ) 2 4H 2 O1.90Kg is made into mixed solution;

[0047] 2) Add ammonia water for co-precipitation and adjust the pH value to 10.50;

[0048] 3) Washing with water to control SO 4 2- Ion content is less than 100ppm, centrifugal dehydration;

[0049] 4) The dehydrated powder is dried at 250°C;

[0050] 5) The dried powder is pre-calcined at 600°C to obtain primary powder;

[0051] 6) The primary powder is calcined in an oxidizing atmosphere, the conditions are: the heating rate is 5°C / min, the temperature is raised to 1000°C, and kept for 10 hours;

[0052] 7) The calcined powder is milled by a vertical ball mill with high-energy ball milling, adding 50 g of modified ammonium polyacrylate, and milling to a medium particle size of D 50 0.40-0.60μm, specific surface area=10.50±1.00m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com