Thin-film solar cell and p-type semiconductor and preparation method of p-shaped semiconductor

A solar cell and semiconductor technology, applied in semiconductor devices, circuits, photovoltaic power generation, etc., can solve the problems of increasing the additional absorption of incident light, large light-induced attenuation, etc., to achieve increased fill factor, short-circuit current and open-circuit voltage, battery The effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

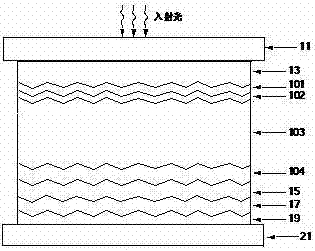

[0033] Such as figure 1 The single-junction amorphous silicon a-Si:H thin-film solar cell shown has the front transparent insulating substrate 11 as the light incident side, and from the light incident side, the front electrodes are laminated in sequence: transparent conductive film 13, p+ layer Amorphous silicon carbide a-SiC:H film 101, p-layer amorphous silicon carbide a-SiC:H film 102, i-layer amorphous silicon a-Si:H intrinsic absorption layer 103, n-layer amorphous silicon a- Si:H thin film 104 , first back electrode layer 15 , second back electrode layer 17 , filling material layer 19 and back transparent insulating plate 21 .

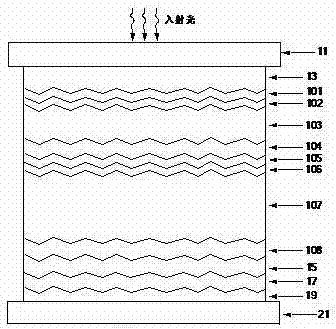

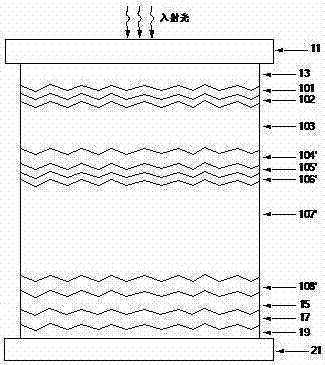

[0034] Such as figure 2 The shown double-junction amorphous silicon a-Si:H / a-Si:H thin-film solar cell uses the front transparent insulating substrate 11 as the light-incident side, and starts from the light-incident side to stack the front electrodes sequentially: transparent Conductive film 13, first junction p+ layer amorphous silicon car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com