Preparation method of modified manganese oxide material for lithium ion batteries

A lithium ion battery, manganese oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high working voltage, capacity decay, low cost, etc., and achieve the effect of uniform distribution of aluminum and uniform microscopic morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1. Precursor preparation by liquid phase two-stage synthesis: manganese sulfate and aluminum nitrate are prepared in a molar ratio of 37:3 with 0.2mol / L aqueous solution, sodium carbonate is separately prepared with 0.2mol / L aqueous solution, and the two sets of solutions The temperature was controlled at 0°C, the two groups of solutions were reacted for 5 hours by co-precipitation method, and then gradually heated to a range of 80°C for 5 hours, filtered and dried to obtain modified precursor white manganese carbonate powder.

[0029] Step 2: Oxidation in high-temperature air: calcining the obtained precursor manganese carbonate powder at 600° C. for 5 hours to obtain a spherical ion-porous structure modified manganese oxide powder with a particle size of 1 μm to 3 μm.

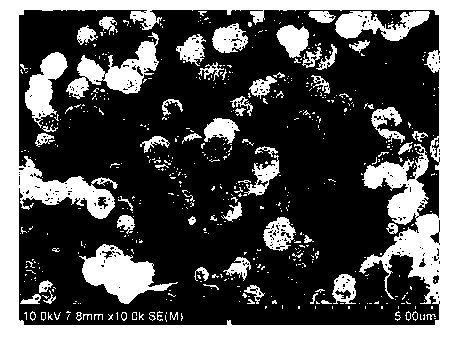

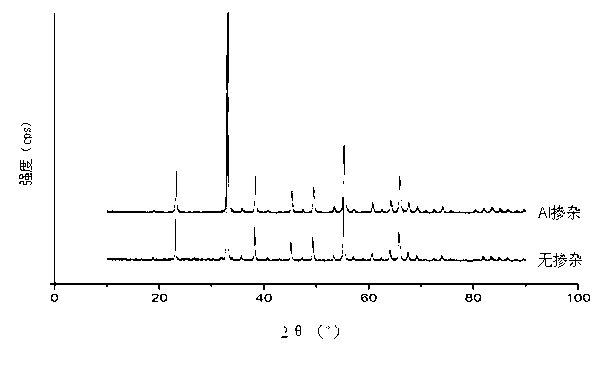

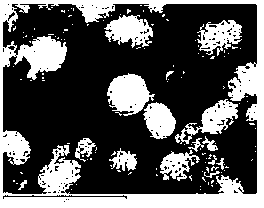

[0030] The scanning electron microscope (SEM) picture of the modified manganese oxide is as follows figure 1 As shown, it can be seen from the figure that the microscopic morphology is a spherical hole-...

Embodiment 2

[0036] Step 1. Precursor preparation by liquid phase two-stage synthesis: manganese sulfate and aluminum nitrate are prepared with a 0.5mol / L aqueous solution at a molar ratio of 39:1, sodium carbonate is separately prepared with a 0.5mol / L aqueous solution, and the two sets of solutions The temperature was controlled at 3°C, and the two groups of solutions were reacted for 4 hours by co-precipitation method, and then gradually heated to 100°C for 4 hours, filtered and dried to obtain modified precursor white manganese carbonate powder.

[0037] Step 2: Oxidation in high temperature air: calcining the obtained precursor manganese carbonate powder at a temperature of 650° C. for 2 hours to obtain a spherical ion hole structure modified manganese oxide powder with a particle size of 1 μm to 3 μm.

Embodiment 3

[0039] Step 1. Preparation of precursor by liquid phase two-stage synthesis method: prepare 0.3mol / L aqueous solution at a molar ratio of 9:1 for manganese sulfate and aluminum nitrate, and separately prepare 0.3mol / L aqueous solution for sodium carbonate. The temperature was controlled at 10°C, and the two sets of solutions were reacted for 8 hours by co-precipitation method, and then gradually heated to 90°C for 8 hours, filtered and dried to obtain modified precursor white manganese carbonate powder.

[0040] Step 2: Oxidation in high-temperature air: calcining the obtained precursor manganese carbonate powder at 700° C. for 4 hours to obtain a spherical ion-porous structure modified manganese oxide powder with a particle size of 1 μm to 3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com