Biofuel production

一种组合物、发酵产品的技术,应用在生物燃料、微生物、基于微生物的方法等方向,能够解决增加成本等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0295] Materials and methods

[0296] Strains and Media

[0297] All chemicals, media components and additives are of analytical grade standard. The genotypes and origins of the plasmids, yeast and bacterial strains used in the experiments are summarized in Table 1. Recombinant plasmids were constructed and amplified in Escherichia coli XL1-Blue. Bacterial strains were grown on rotating wheels in Terrific Broth or on LB agar (Luria-Bertani agar) at 37°C (Sambrook et al., 1989). Add ampicillin for selection of resistant bacteria to a final concentration of 100 μg ml -1 . Fungal strains were grown at 30°C on a rotary shaker set at 100 rpm. Aspergillus strains were grown in maltodextrin medium (5% maltodextrin, 0.6% NaNO 3 , 0.15% KH 2 PO 4 , 0.05% MgSO 4 , 0.05% KCl, and trace elements). Fungal strains were stored at 30°C in minimal medium (1% glucose, 0.6% NaNO 3 , 0.2% peptone, 0.15% KH 2 PO 4 , 0.1% yeast extract, 0.1% casamino acids, 0.05% MgSO 4 , 0.05% KCl, 2...

Embodiment 2

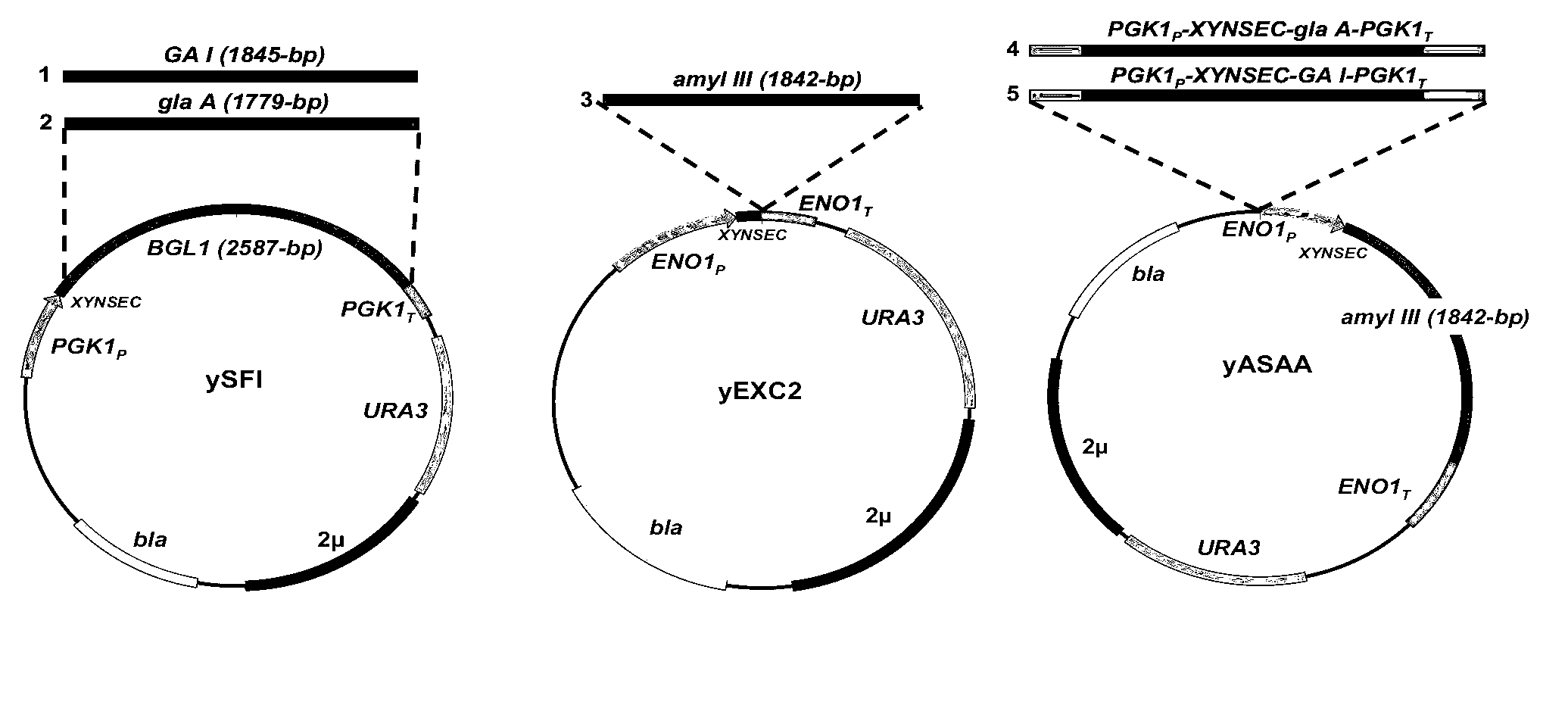

[0388] Embodiment 2: Design novel amylolytic yeast strain for the production strain and medium of industrial ethanol

[0389] All chemicals, media components and additives are of analytical grade standards. Recombinant plasmids were constructed and amplified in E. coli DH5α. Bacterial strains were grown in broth at 37°C on a turntable (Sambrook et al., 1989). Add ampicillin as a selection of resistant bacteria to a final concentration of 100 μg ml -1 . Saccharomyces cerevisiae strains can be grown in YPD medium (1% yeast extract, 2% peptone and 2% glucose) containing other growth factors and amino acids if necessary at 30 °C on a rotary shaker set at 100 rpm and selective complete medium (2% glucose and 0.17% yeast nitrogen source without amino acid).

[0390] DNA processing

[0391] Restriction enzyme digestion, electrophoresis, DNA ligation, transformation and DNA preparation from E. coli were performed using standard methods according to Sambrook et al. (1989). Purifi...

Embodiment 3

[0408] Example 3: Screening and development of an effective saccharification yeast strain for the production of industrial ethanol

[0409] Screening of Saccharomyces cerevisiae and non-Saccharomyces cerevisiae strains for the production of extracellular hydrolases

[0410] The media used in this study are shown in Table (a) below. All chemicals, media components and supplements were of analytical grade.

[0411] culture medium

reference or supplier

Edimburgh Minimal Medium (EMM)

Favaro et al., 2008

Minimal Media Yeast (MMY)

Favaro et al., 2008

DIFCO

Wollum medium

Wollum et al., 1982

[0412] Table (a). Summary of media used in this study

[0413] Screening of Saccharomyces cerevisiae and non-Saccharomyces cerevisiae strains for the production of extracellular hydrolases

[0414] 220 S. cerevisiae strains and 180 non-S. cerevisiae isolates were screened for amylolytic activity. Saccharomyces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com