Composite material connecting structure

A composite material and fiber composite material technology, which is applied in the field of high-strength composite material connection structures, can solve problems such as unfavorable large-scale production, high cost and fiber waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] Preparation of composite parts

[0092] A general method for preparing a composite material part with the composite material connection structure of the present invention comprises the following steps: preparing a fiber preform of the composite material with openings in the corresponding parts, and fixing the reinforcing sheet of the present invention on the composite material fiber After the corresponding position of the preform is solidified and molded, and then the parts are connected by bolts; or the reinforcing sheet is fixed at the corresponding position of the formed open-hole composite material, and after the secondary curing and molding, pass the fastener ( such as bolts) for assembly.

[0093] Fabrication of Composite Connected Structures

[0094] According to the shape, size and force of the hole in the composite laminate, design a suitable reinforcement sheet, use the prepared reinforcement sheet to reinforce the hole in the composite laminate, and then con...

Embodiment

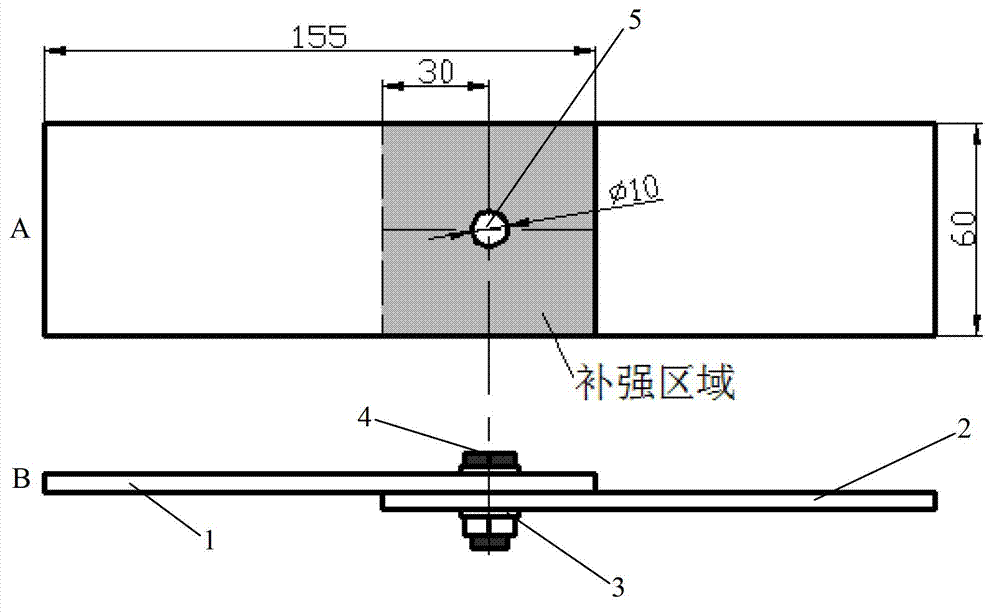

[0112] First, prepare as figure 1 Fiberglass / epoxy composite bolted specimens of dimensions indicated. The preparation method of the above-mentioned glass fiber / epoxy resin composite material bolt connection sample is as follows:

[0113] Step 1: In finite element analysis software such as ANSYS or ABAQUS, perform force analysis on the composite components connected by fasteners to obtain the principal stress distribution around the screw holes.

[0114] Step 2: According to the principal stress vector distribution around the opening, use relevant software to draw the trajectory of tensile stress and compressive stress respectively.

[0115] Step 3: On the basis of the principal stress trajectory obtained in step 2, arrange the circular helical trajectory along the tensile stress trajectory, arrange the radial trajectory along the compressive stress trajectory, and finally connect these trajectories into a whole to form a complementary The fiber placement track of the strong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com