Biological membrane fluidized bed wastewater treatment method

A wastewater treatment and biofilm technology, which is applied in biological water/sewage treatment, sustainable biological treatment, processing wastewater treatment, etc., to reduce costs, improve wastewater treatment efficiency, and reduce gas flow rates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

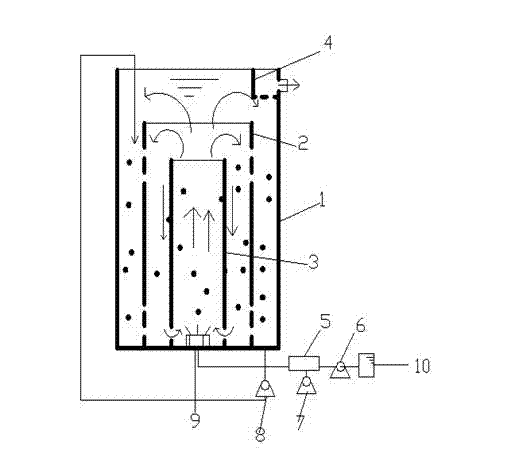

Image

Examples

Embodiment 1

[0018] Embodiment 1. Treatment of printing and dyeing wastewater. The influent COD is 2000-3000mg / l, the dosage of filler is 0.1% of chemical wood pulp, and the volume load is 3.93kgCOD / m 3 .d, the COD removal rate of printing and dyeing wastewater by this process is 85%-90%.

Embodiment 2

[0019] Embodiment 2, treatment of waste paper deinking wastewater, influent COD is 1500-2000mg / l, filler dosage is chemical wood pulp 0.3% and 0.3% chemical mechanical pulp, volume load 6.51kgCOD / m 3 .d, the COD removal rate of waste paper deinking wastewater by this process is 85%-90%, and the removal rate of BOD reaches more than 95%.

Embodiment 3

[0020] Embodiment 3, treatment of high-concentration organic wastewater, influent COD is 10000-15000mg / l, the dosage of filler is 0.4% of chemical wood pulp, 0.3% of chemical straw pulp and 0.3% of chemical mechanical pulp, and the volume load is 4.72kgCOD / m 3 .d, the process has a COD removal rate of 80%-85% for high-concentration organic wastewater, a BOD removal rate of 90%-95%, and an ammonia nitrogen removal rate of more than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com