Processing method of field emitting cathode

A field emission cathode and processing method technology, applied in the field of FED, can solve the problems of film damage, unsatisfactory field emission performance, affecting the field emission performance of CNTs film, etc., and achieve the effect of increasing the emission current and reducing the field strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

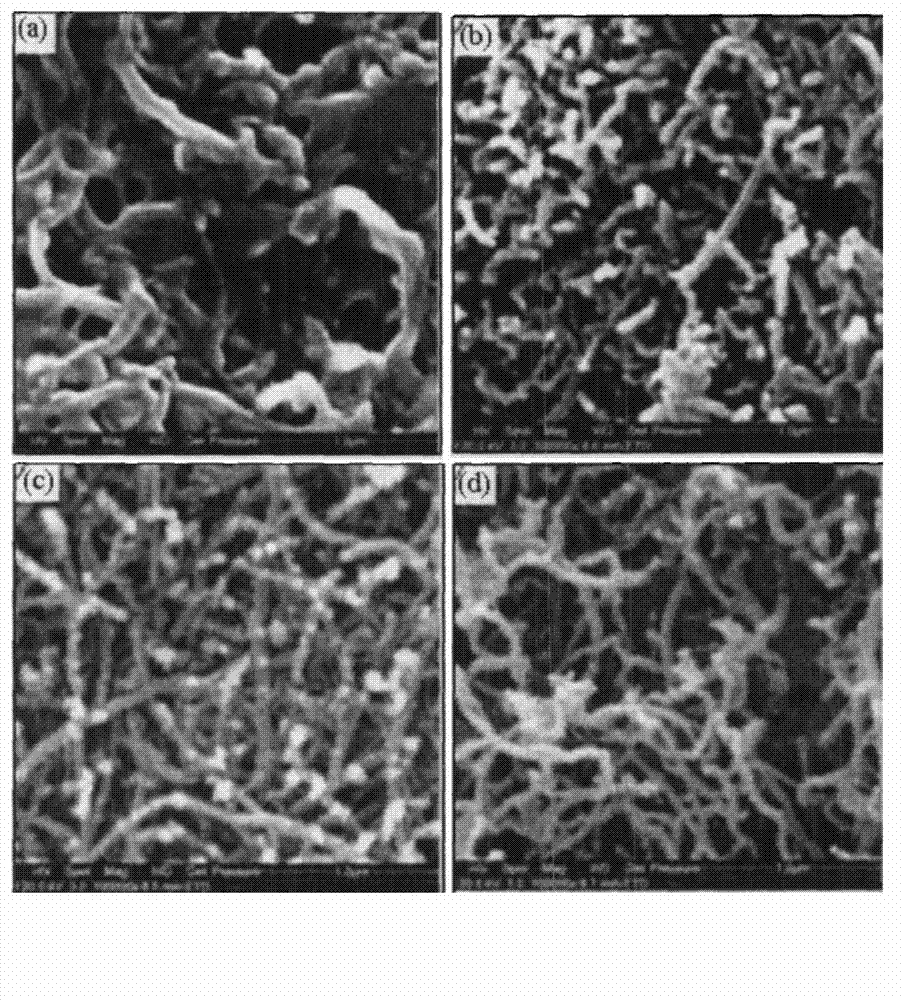

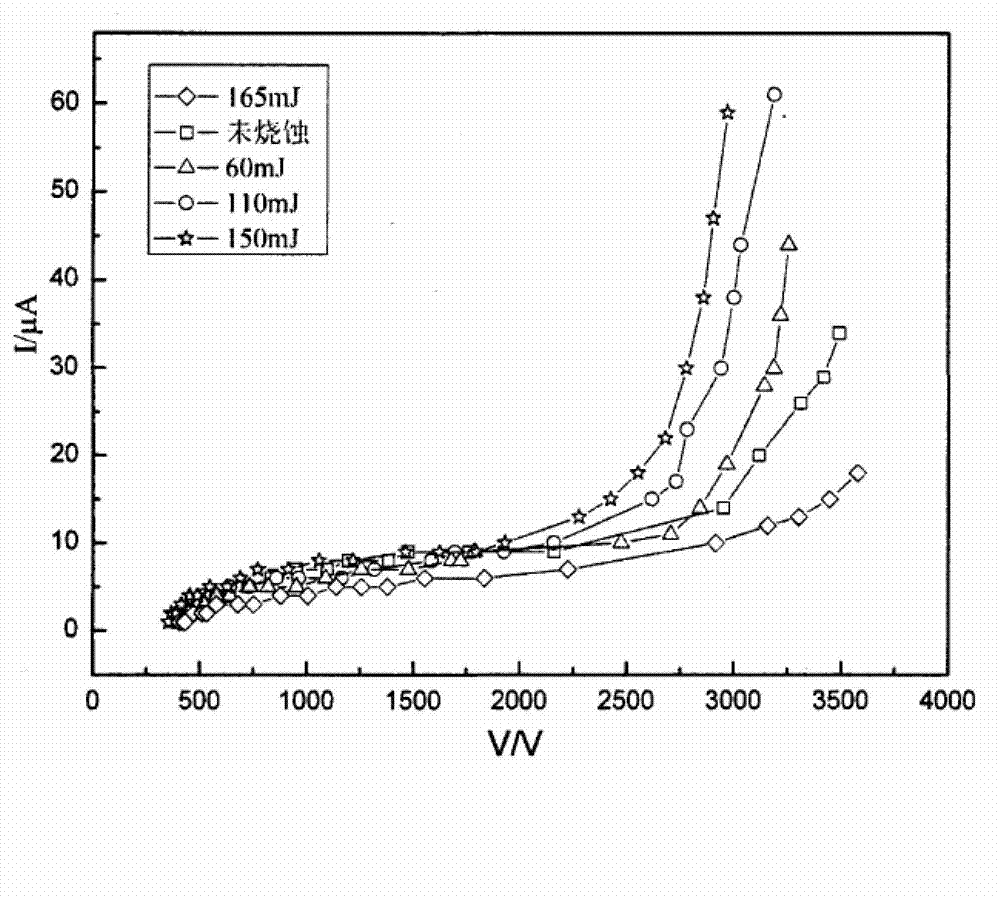

[0015] (l) Preparation of MWCNTs thin film

[0016] The MWCNTs used in the present invention are prepared by chemical vapor deposition (CVD). The diameter is 20~40nm, and the length is about 5μm. The purified MWCNT powder was dispersed in anhydrous ethanol by ultrasonic waves, dried naturally at room temperature and fully ground, then mixed with an organic vehicle and stirred for 1-2 hours as a cathode slurry. Print a layer of silver paste film electrodes with an area of 60mm×25mm on the glass substrate. After the sintering treatment, the prepared carbon tube slurry is used to print the carbon tube film on the center of the substrate with a 200-mesh screen. All the samples were put together in a tube furnace and sintered under Ar environment before use.

[0017] (2) Laser ablation treatment

[0018] A Lambda Physik comPex102 KrF excimer laser system was used in this experiment. The output wavelength of the laser is 248nm, and the pulse width is 30ns. The laser has a la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com