Manufacturing method of oxide thin film transistor

A technology of oxide film and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to achieve the effect of reducing process difficulty, avoiding current crowding, and reducing process temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

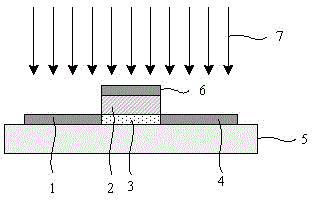

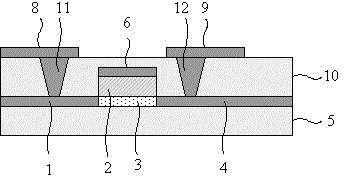

[0028] refer to figure 1 and 2 A partial structure of a coplanar oxide thin film transistor includes a substrate 5, an oxide semiconductor layer, a gate insulating layer 2 and a gate 6, and an oxide semiconductor layer is formed on the surface of the substrate 5, and the oxide semiconductor layer includes The channel region 3 opposite to the gate 6, and the first contact region 1 (for contacting the source 8 ) and the second contact region 4 (for contacting the drain 9 ) on both sides of the channel region 3 contact region), the channel region 3 is located between the first contact region 1 and the second contact region 4 , a gate insulating layer 2 is formed on the oxide semiconductor layer, and a gate 6 is formed on the gate insulating layer 2 .

[0029] The manufacturing method of the coplanar oxide thin film transistor of this embodiment includes the following steps:

[0030] (1) Reference figure 1 , deposit an oxide semiconductor thin film on glass, quartz, silicon waf...

no. 2 example

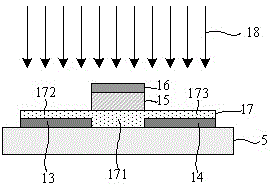

[0046] Such as image 3 As shown, a schematic cross-sectional view of a top-gate thin film transistor, the thin film transistor includes a substrate 5, a source 13 and a drain 14 formed on the substrate 5, an oxide semiconductor layer 17 formed on the source 13 and the drain 14 , the gate insulating layer 15 formed on the oxide semiconductor layer 17, the gate 16 formed on the gate insulating layer 15, the oxide semiconductor layer 17 includes a channel region 171 opposite to the gate 16, and the The first contact region 172 (in contact with the source 13) and the second contact region 173 (in contact with the drain 14) on both sides of the channel region 171, the channel region 171 is located between the source 13 and the drain 14; wherein the gate 16 Self-alignment can be formed with the gate insulating layer 15 and the channel region 171 .

[0047] Such as Figure 4 As shown, another top gate oxide thin film transistor structure, the thin film transistor includes a substr...

no. 3 example

[0057] refer to Figure 6 It is a schematic cross-sectional view of a bottom-gate thin film transistor according to the third embodiment. The thin film transistor includes a substrate 5, a gate 30 formed on the substrate 5, a gate insulating layer 32 formed on the gate, and a gate insulating layer 32 formed on the gate insulating layer. 32, an etching stopper layer 33 formed on the oxide semiconductor layer 31, source and drain electrodes 34 and 35 formed on the oxide semiconductor layer 31, the oxide semiconductor layer includes A standard channel region 311 , a first contact region 312 (contacting to the source 34 ) and a second contact region 313 (contacting to the drain 35 ) respectively located on both sides of the channel region 311 .

[0058] The manufacturing method of the bottom gate oxide thin film transistor of this embodiment includes the following steps.

[0059] (1) Reference Figure 6, form a grid conductive layer on glass, quartz, silicon wafer or other flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com